5 HUSKYTOOLS.COM

Please contact 1-877-260-1630 for further assistance.

APPLICATIONS

You may use this product for the purposes listed below:

• Driving Screws, lag bolts

• Tightening nuts and bolts

• Removing screws, nuts and bolts

OPERATION

Switch Trigger

To turn the impact driver ON, depress the switch trigger. To turn it

OFF, release the switch trigger..

Variable Speed

This tool has a two-step trigger that delivers higher speed with

increased trigger pressure. Speed is controlled by the amount of

switch trigger depression.

Direction for Rotation Selector (Forward / Reverse)

The direction of bit rotation is reversible and is controlled by side

mounted forward/reverse switch.

Installing / Removing Bits

To install:

Remove air supply from the impact driver.

Pull back the coupler sleeve and insert bit. Release sleeve

and bit will lock in place.

Pull on the bit to ensure it is secured in the coupler.

There may be some play in the installed bit; this is

normal.

NOTE: Use only impact quality bits with a locking

groove.

Make sure the bit is secured

in the coupler before using the impact

driver. Failure to do so could cause

serious personal injury.

To remove:

Remove the air supply from the impact driver.

With the nose of the tool pointed away from

you, pull the coupler sleeve back.

The bit can be removed.

Driving or Removing Screws

Place the direction of rotation selector in the

correct position for the operation.

Hold the impact driver with one hand.

Place the bit on the screw head and slowly

depress the switch trigger. Start the bit slowly

for more control.

As screw is driven, impacting will begin.

Maintenance

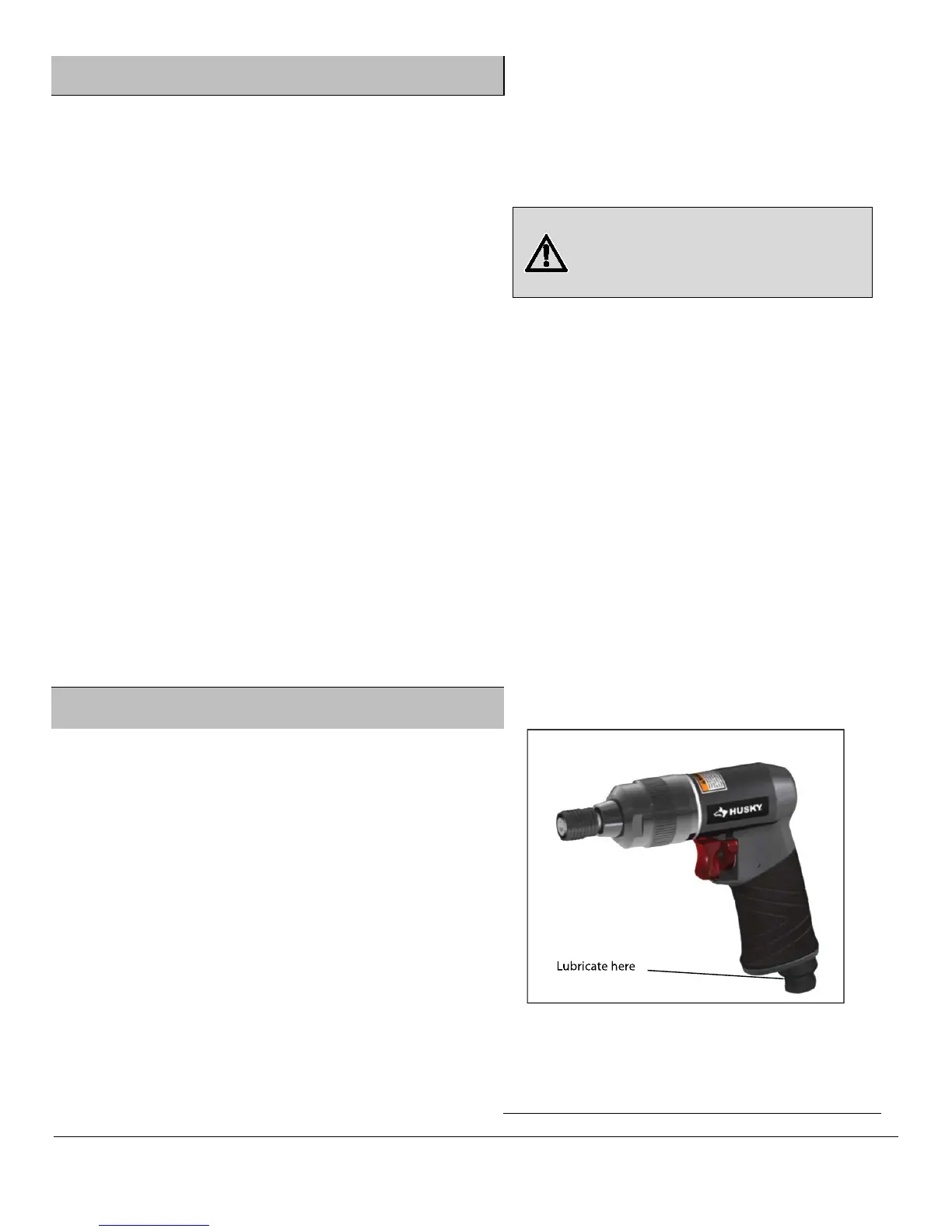

Lubrication

An in-line filter-regulator-lubricator is recommended as it increases

tool life and keeps the tool in sustained operation. The in-line

lubricator should be regularly checked and filled with air tool oil.

Proper adjustment of the in-

line lubricator is performed by placing a

sheet of paper next to the tools exhaust ports and holding the

throttle open approximately 30 seconds. The lubricator is properly

set when a light stain of oil collects on the paper.

Excessive amounts of oil should be avoided. In the event that it

becomes necessary to store the tool for an extended period of time

(overnight, weekend, etc.), it should receive a generous amount of

lubrication through the air inlet. The tool should be run for

approximately 30 seconds to ensure oil has been evenly distributed

throughout the tool. The tool should be stored in a clean and dry

environment.

Recommended lubricants: Use air tool oil or any other high grade

turbine oil containing moisture absorbent, rust inhibitors, metal

wetting agents and an EP (extreme pressure) additive.

Loading...

Loading...