Do you have a question about the Husqvarna 3010 and is the answer not in the manual?

Procedure for checking machine parts for wear, breakage, or defects.

Specific electrical diagnostics and calibration procedures for model 6570.

General procedures for maintaining and calibrating the sewing machine.

Procedures for repairing individual mechanical or electrical components.

Adjusting the tension of the thread coming from the bobbin case.

First method for setting the upper thread tension accurately.

Second method for setting the upper thread tension accurately.

Procedures for removing the bobbin spindle.

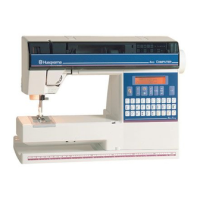

| Brand | Husqvarna |

|---|---|

| Model | 3010 |

| Category | Sewing Machine |

| Language | English |