Do you have a question about the Husqvarna 3230 and is the answer not in the manual?

Explains the electric motor's function and connection to the sewing machine.

Details power transmission from motor to machine via V-belt and reduction gear.

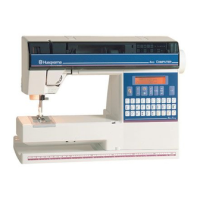

| Brand | Husqvarna |

|---|---|

| Model | 3230 |

| Category | Sewing Machine |

| Language | English |