13

Tuff Torq K61 Hydrostatic Transaxle

6. Remove the (2) Thrust Metals (bearing pads) from the

Upper Case. (Fig. 36)

Fig. 36, Thrust Metal Bearing Removal

Inspect Thrust Bearing components for pitting,

scoring, discoloration, missing rollers, and roller retain-

er breakage.

Fig. 37, Cylinder Block Assembly & Swash Plate

Swash Plate Removal

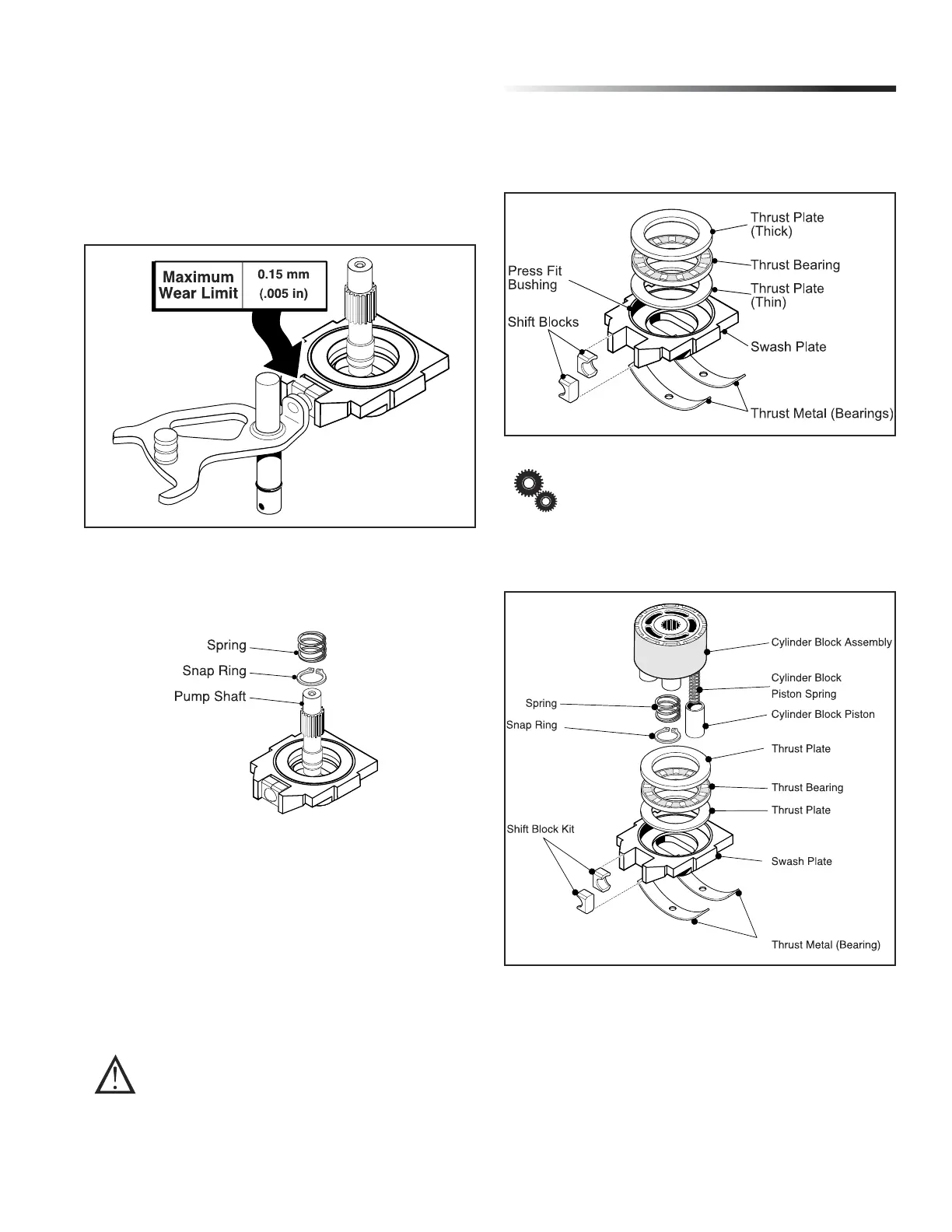

1. Before removing the Swash Plate Assembly measure the

clearance (using Feeler gauge) between edge of Swash

Plate’s Slot and the Shift Blocks. If the clearance (gap) is

> 0.15 mm (0.005 in), replace both Shift Blocks and the

Swash Plate Assembly, simultaneously. (Fig. 34)

Fig. 34, Shift Blocks Clearance Tolerance

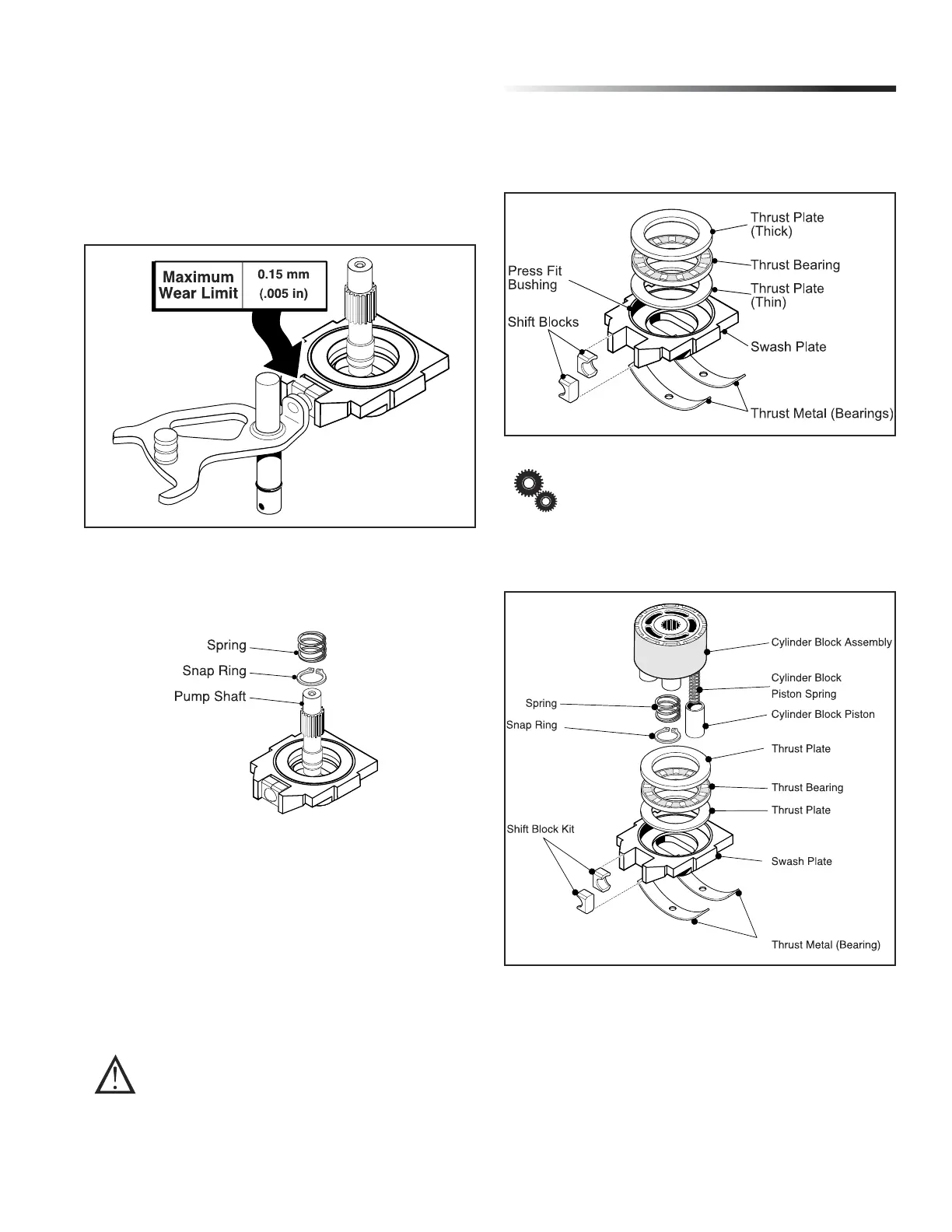

2. Remove the Spring and the Snap Ring. (Fig. 35)

Fig. 35, Swash Plate Removal

3. Remove the Thrust Bearing seated in the Swash Plate.

(Fig. 36)

4. Remove the Swash Plate. (Fig. 36)

5. Inspect the press-fit Bushing in the Swash Plate for

burrs, scoring, pitting, discoloration, and wear. If dam-

age, replace the Swash Plate. The press-fit Bushings are

not serviceable separately.

Do not attempt to remove the press-fit Bushing

in the Swash Plate. If damaged, replace Swash Plate

Assembly (press-fit Bushing is included in the assem-

bly).

Loading...

Loading...