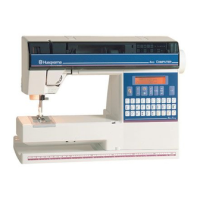

Do you have a question about the Husqvarna VIKING HUSKYLOCK 936 and is the answer not in the manual?

| Brand | Husqvarna |

|---|---|

| Model | VIKING HUSKYLOCK 936 |

| Category | Sewing Machine |

| Language | English |

Instructions for service personnel and salesmen.

Technical specifications of the sewing machine.

Diagram and list of machine components.

Steps for disassembling the sewing machine.

Calibration marks for setting the machine's cams.

Setting the distance between the needle and stitch plate.

Adjusting the vertical position of the lower looper.

Setting clearance between lower looper and needles.

Setting lower looper position relative to the needle.

Clearance between needle support and needle.

Setting the upper looper clutch mechanism.

Setting the upper looper position relative to the needle.

Aligning the upper and lower loopers for correct timing.

Setting clearance between upper and lower loopers.

Adjusting the height of the chain stitch looper.

Setting clearance between double chain looper and needle.

Timing the double chain looper to the needle.

Clearance between needle support and needles.

Setting sideways clearance for feed dogs and stitch plate.

Adjusting the front-to-back position of the feed dog.

Setting the height of the rear feed dog.

Setting the height of the front feed dog.

Setting the position of the lower knife.

Setting the position of the upper knives.

Adjusting the motor belt tension.

Adjusting the speed sensor for proper motor operation.

Setting thread take-up distances to guides.

Adjusting the chain stitch looper take up lever height.

Setting and checking the stitch length.

Adjusting and checking differential feeding.

Setting and checking thread tension.

Setting the height of the presser foot.

Diagram labeling key electrical components of the machine.

Diagram illustrating power, motor, and control circuit connections.

Diagnosing and resolving mechanical sewing problems.

Troubleshooting skipped stitches related to looper interaction.

Diagnosing and resolving needle and looper thread breaks.

Addressing fabric feeding problems and material shrinkage.

Troubleshooting knife cutting problems and thread tension.

Diagnosing and resolving electronic and motor related problems.

Troubleshooting LCD, safety switch, and buzzer malfunctions.

Resolving issues with feeding, lighting, and general machine operation.