ML49810/MP34.9576

31JAN12

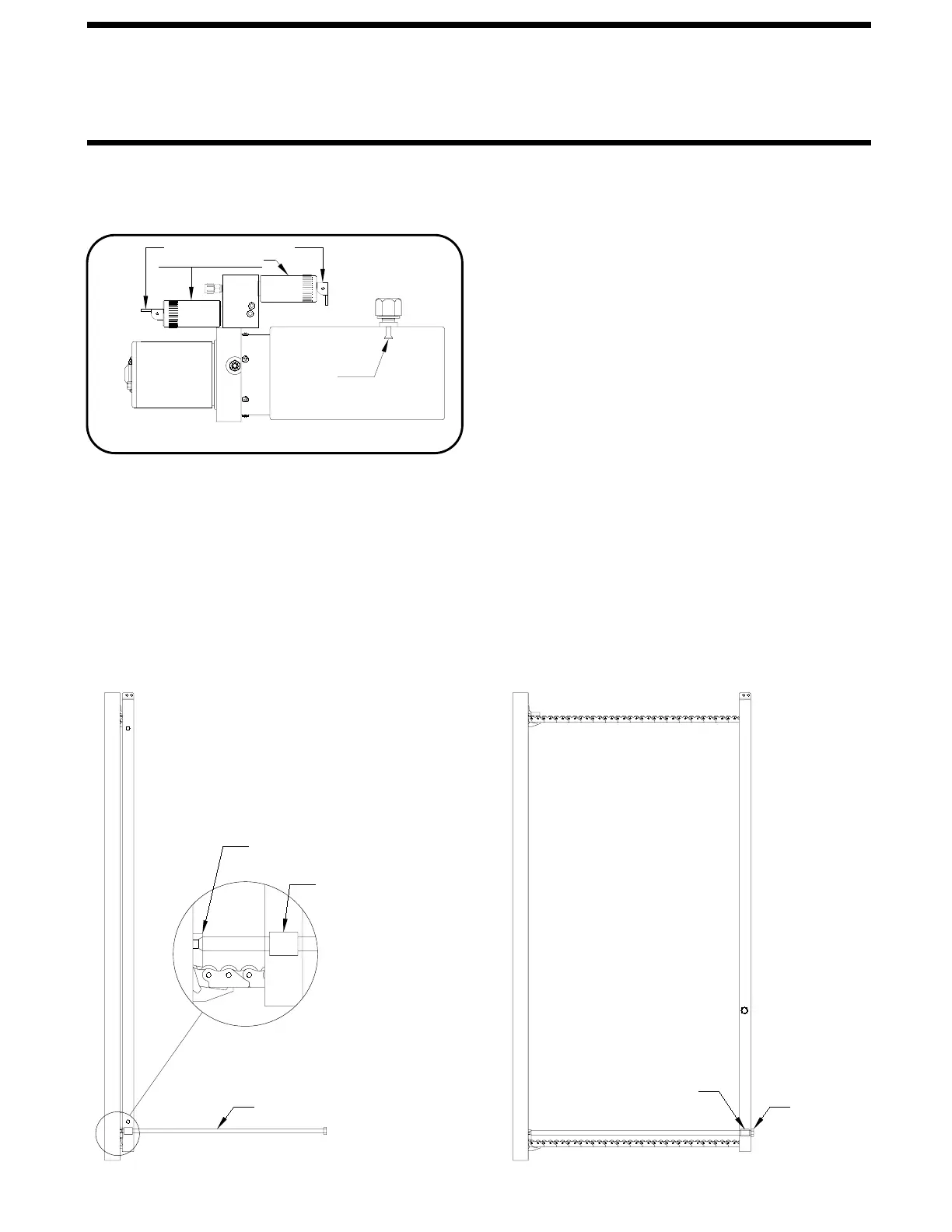

PLATE

RECEIVER

ROD

THREADED

ROOM EXTENDED

THREADED

BLOCK

ROOM RETRACTED

BLOCK

THREADED

THREADED

ROD

manufacturer.

the front and one for the rear mechanism should be provided.

3. Start both threaded rods until resistance is met, one for

NOTE: To access the threaded blocks refer to vehicle

to step 2.

retracted. Leave the floor solenoid valves open and proceed

1. After the floor is completely lowered, the room can be 5. Move to the other room extension mechanism, rotate

the room, contact HWH Customer Service for assistance

understood or if the room begins to bind DO NOT force

IMPORTANT: If at any stage something is not

7. Repeat steps 4 and 5 alternating from mechanism to

mechanism rotating each threaded rod 12 complete

turns until room is sealed. (DO NOT exceed 15

6. Return to the first room extension mechanism and rotate

the threaded rod clockwise 12 complete turns.

the threaded rod clockwise 12 complete turns.

ft.lbs) Make sure the room does not bind.

1-800-321-3494.

Do Not use an impact wrench.

either mechanism’s threaded rod clockwise 6 complete turns.

a personal wrench or a tire iron with a 1-1/8" opening rotate

4. Using wrench provided,

threaded rods impact the coach wall or the mechanism.

Be careful to not extend the room so far that the

threaded rods out and slightly extending the room.

threaded rods completely, alternate backing the

NOTE: If there is not enough room to remove both

ROOM HAS BEEN SERVICED. ANY SOLENOID VALVES

RODS SHOULD BE COMPLETELY REMOVED.

LEFT OPEN SHOULD BE CLOSED AND THE THREADED

IMPORTANT: DO NOT EXTEND THE ROOM UNTIL THE

threaded rods in place until the room has been

NOTE: Leave the solenoid valves open and the

serviced.

PAGE 2 OF 2

UNIVERSAL LEVEL IN/LEVEL OUT ROOM EXTENSION MECHANISM

OPERATING PROCEDURES

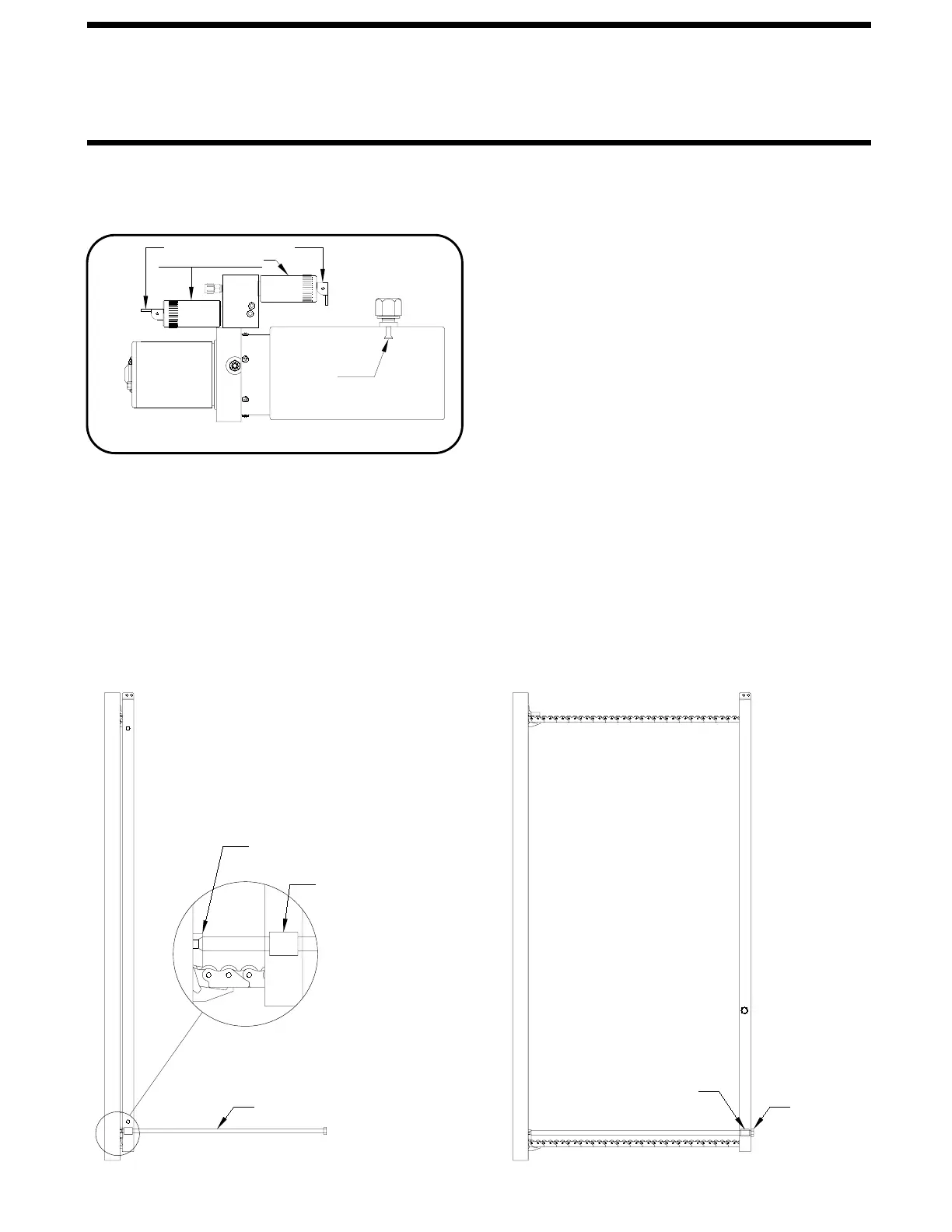

VALVE RELEASE CAMS

SOLENOID VALVES

HYDRAULIC PUMP/MANIFOLD

(VALVE CLOSED)

(VALVE OPEN)

CAP-DIP

BREATHER

STICK

MANUAL ROOM RETRACTION PROCEDURES - SPLINED TORSION SHAFT

room mechanism.

2. Locate and open both solenoid valves for the

Loading...

Loading...