Installation and maintenance manual

H.I.B Hydac International Page 34 of 36

Version: G/DV

Date: 11.01.2023

For the conservation of the following warranty please:

Enclose a precise description of the defect with your letter.

Enclose the proof of purchase in the form of a copy of a delivery note or invoice.

Note on it the type and manufacturing reference number and serial number of the device.

15.0 Shutdown of the unit

If the unit some time out of service, we recommend the coolant drained off. Frost damage is

excluded from all liability.

Please be aware if a turbine flow control is installed in the chiller, it is

not allowed to blow out the tube system by compressed air. In this case the flow control can be

damaged.

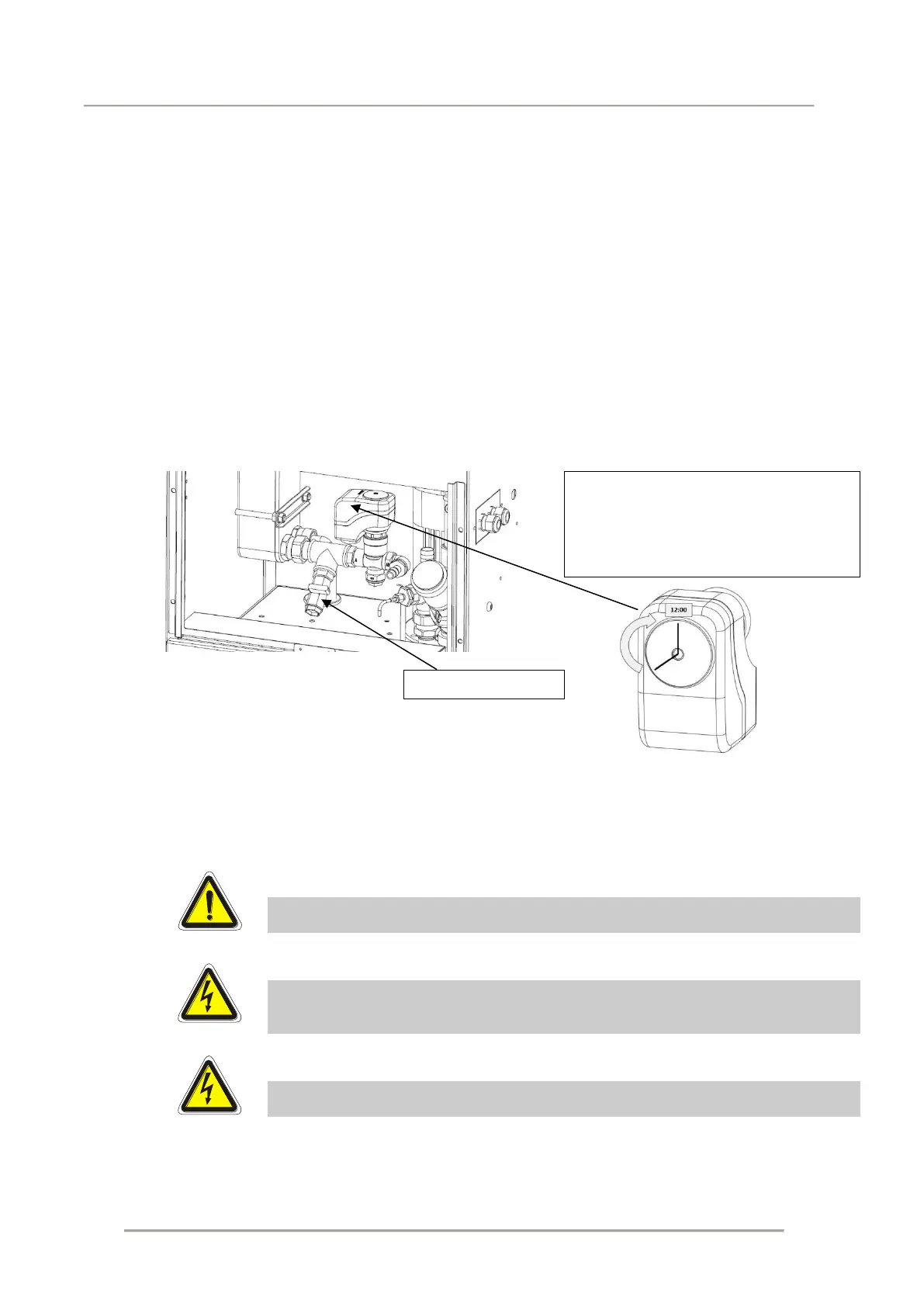

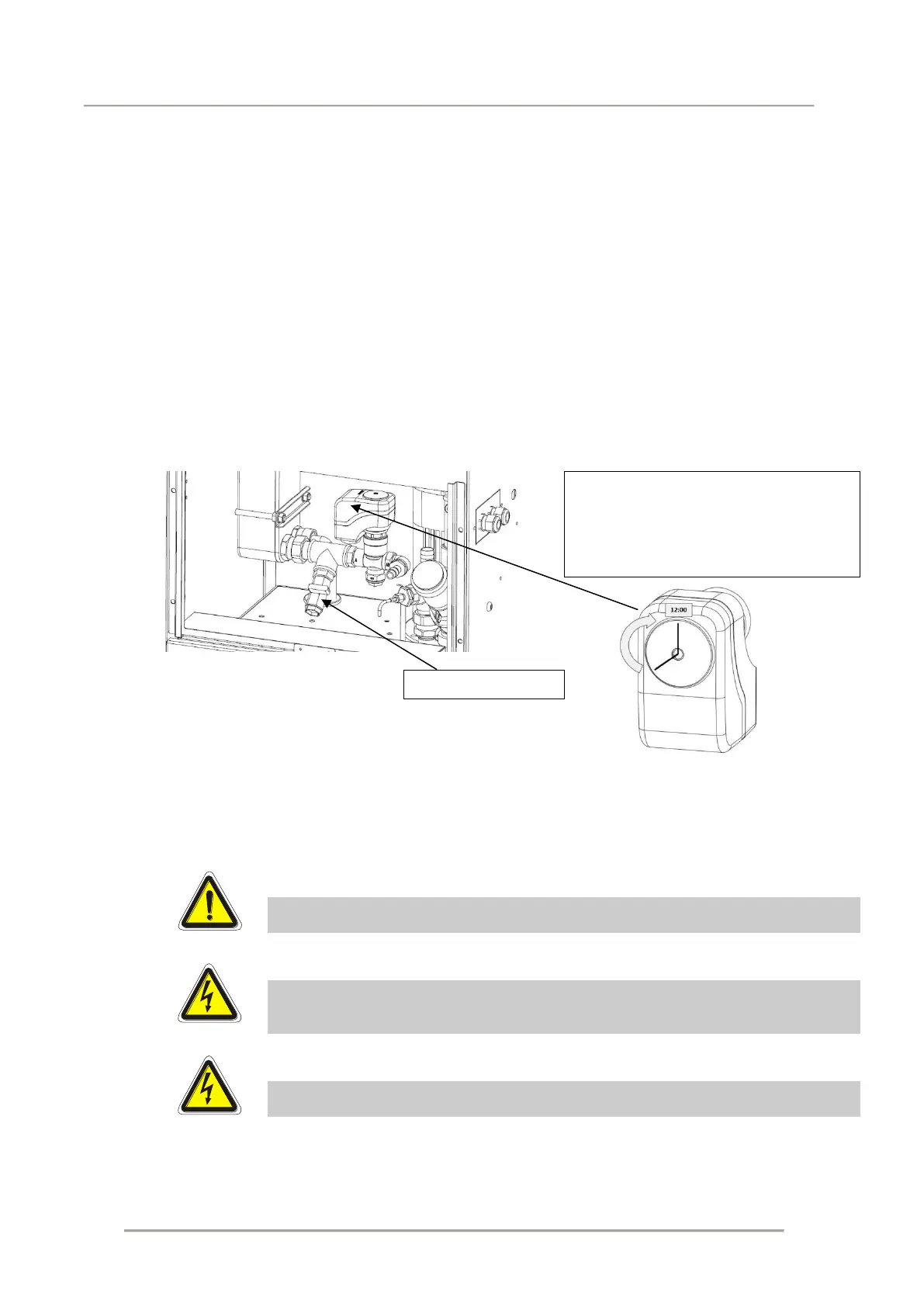

15.1 Emptying the PHE during shipping or storage below 0 ° C (optional)

Empty the tank. (see section - Empty the tank)

Open the ball valve completely to empty the PHE.

schematic diagram

16.0 Repair and Troubleshooting

If the operation a failure occur at the last chiller that you want to search using the interference of

the table makes it easier in the plant. If in doubt, you should always consult a specialist (expert).

When working in the refrigeration cycle is to ensure adequate ventilation.

Check available power supply voltages to the nameplate of the unit.

Repairing the refrigerant circuit may be done by an expert firm only, please contact

the manufacturer

As a rule, work on the electrical system must be carried out by expert personnel; the

valid wiring diagram and the VDE guidelines must be observed. Compare the mains

voltage at site with the nameplate of the unit.

After two short-circuit shutdowns, the power, motor and main switch (if present) must

be revised or replaced.

Check before emptying the position of the

motor control valve.

The controller must be turned by hand with

a hex wrench (Allen) wrench size 3mm to

12:00 clock.

Loading...

Loading...