4000 SRM 481 Free-Lift Cylinder Repair

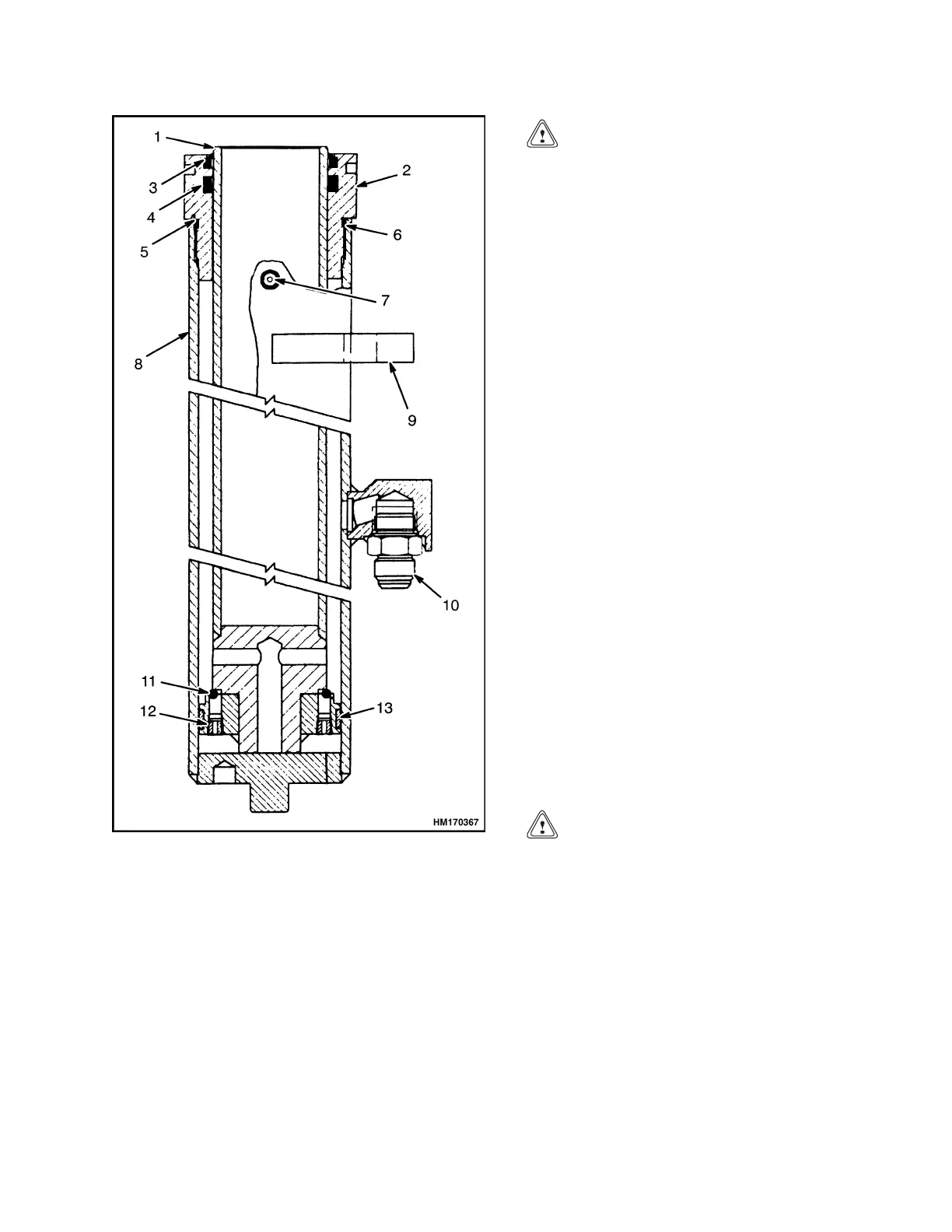

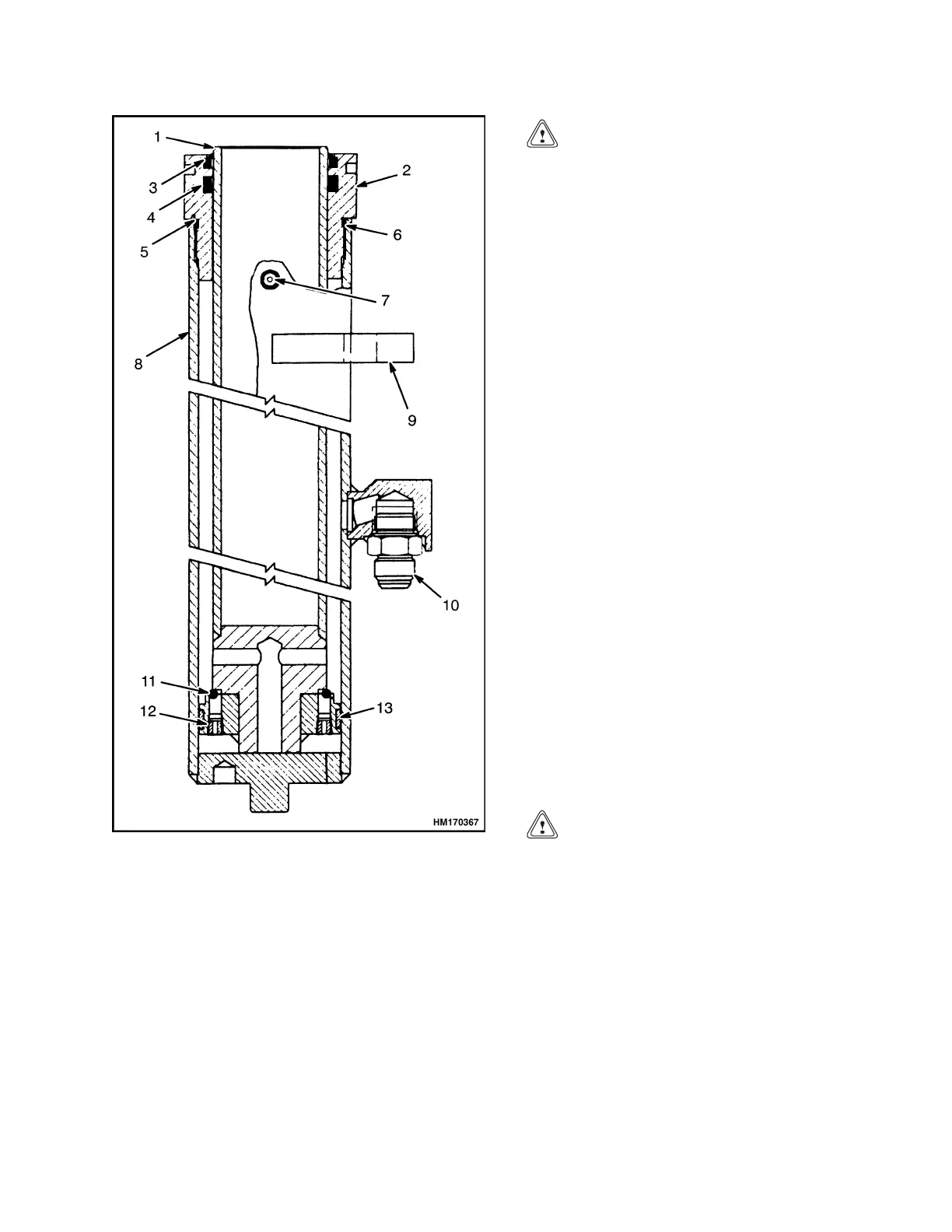

1. ROD

2. RETAINER

3. WIPER RING

4. SEAL

5. O-RING

6. BACKUP RING

7. BLEED SCREW

AND SEAL

8. SHELL

9. CHAIN ANCHOR

10. LOWERING

CONTROL VALVE

(ALL CYLINDERS)

11. STEEL BALL

12. PLUG

13. WEAR PLUG

Figure 5. Free-Lift Displacement Cylinders

CAUTION

A difficult and important step in assembling

lift cylinders is the correct installation of the

seals. Most lift cylinder maintenance is caused

by seal leaks. Special installation sleeves come

in the seal kits.

1. Install the internal check valve, if installed. See

Figure 5. Make sure the arrow on the internal

check valve is toward the base of the piston.

2. Install the wear ring, single lip seal, and backup

ring onto the piston assembly. If a spacer is used,

installit. Useshimmaterialandaclampasa

guide to move the seal over the threads of the

shell.

3. Carefully push the piston and rod assembly into

the shell. Release the clamp on the seal when the

seal travels past the threads of the shell.

4. Install the seal, O-ring, wear ring, and wiper ring

in the retainer. If the wiper ring has a spring for a

backup ring, the spring must be toward the base

of the lift cylinder.

5. Carefully install the retainer on the piston rod.

6. Engage the threads and tighten the retainer

in the shell to the proper torque. Refer to Ca-

pacities and Specifications 8000 SRM 1198,

Capacities and Specifications 8000 SRM

1028, Capacities and Specifications 8000

SRM 1380, or Capacities and Specifications

8000 SRM 972 for your truck model. Use the cor-

rect spanner wrench. DO NOT hit the retainer

with a hammer and driver.

CAUTION

Wrong in

stallation of the special washer and

spring c

an make the load lower too fast.

7. Install

the lowering control valve. Make sure the

special

washer and the spring are installed cor-

rectly.

A wrong installation can cause the load to

lower to

ofast.

8. See the s

ection Mast, Repair 4000 SRM 482 for

cylind

er installation in the mast assembly.

7

Loading...

Loading...