Current Amperage

The current amperage should be divided into the control power capacity and motor power capacity.

In this guide, describes about the current amperage of the control power supply and 200V motor power

supply. For the current amperage of the 24V motor power supply, refer to the first step guide (ME0383) and

instruction manual (DVD) of RCON 24V Driver Unit.

The control power supply should be input from the control power supply connector on the gateway unit. The

motor power supply should be input from the 200V input connector on the 200V power supply unit.

The specifications related to the power capacities should be as shown below.

[Control Power Supply]

Item Specification

Power Supply Voltage 24V DC ±10%

Control Power Capacity

(for one unit)

Gateway unit

(terminal unit included)

RCON Gateway Unit

0.8A (Ethernet option: Not equipped)

1.0A (Ethernet option: Equipped)

SEL Unit 1.2A

24V Driver unit

Brake: Not equipped 0.2A

Brake: Equipped (one-axis type) 0.4A

Brake: Equipped (two-axis type) 0.6A

200V Driver uni

(200V power supply

unit included)

Brake: Not equipped 0.2A

Brake: Equipped 0.5A

Extension unit

SCON Extension Unit 0.1A

PIO/SIO/SCON Extension Unit 0.3A

PIO Unit 0.2A

Simple absolute unit (in common for all types) 0.2A

EC Connection Unit 0.1A

[200V Motor Power Supply]

Actuator Motor Wattage Motor Power Capacity Peek Max. Motor Power Capacity

60 138 414

60 (RCS3-CTZ5) 197 591

100 234 702

100S (LSA) 283 851

150 328 984

200 421 1263

200S (DD) 503 1509

200S (Excluding LSA (S)-N15H) 486 1458

200S (LSA (S)-N15H) 773 2319

300S(LSA) 662 1986

400 920 2760

400 (RCS3-CT8) 1230 3690

600 1164 2328

600 (DD) 1462 4386

750 1521 3042

750S 1521 4563

Restrictions in Unit Connection

(1) Current Restrictions

Shown below is the restricting values of current for selecting calculation.

Item Restricting Value of Current for Selecting Calculation

Control Power Supply (CP) 9.0A or less

The capacity necessary in the control power supply should be figured out by [Total of control power

capacity of used units].

In the table of the capacity [Control Power Supply] shown above, add the power capacity of all the units

constructing the system and check that it does not exceed the restricting values of current for selecting

calculation described in Restrictions in Unit Connection.

Also, the gateway units should not be included for the calculation.

Shown below is some examples for calculation.

[Control Power Supply] * The gateway units should not be included for the calculation.

Example 1

200V Actuator × 8 axes, All axes equipped with brake

200V Driver unit (with brake) 0.5A × 8 = 4.0A ⇒ OK

Example 2

200V Actuator × 16 axes, All axes equipped with brake

200V Driver unit (with brake) 0.5A × 16 = 8.0A ⇒ OK

Example 3

24V Actuator × 8 axes, All axes equipped with brake (2 axes/unit), All axes simple absolute type

200V Actuator × 8 axes, All axes equipped with brake

24V Driver unit (with brake) 0.6A × 4 + Simple absolute 0.2A × 8

+200V Driver unit (with brake) 0.5A × 8 = 8.0A ⇒ OK

Example 4

200V Actuator × 16 axes, All axes equipped with brake + PIO/SIO/SCON Extension Unit one unit, PIO Unit 7 units

200V Driver unit (with brake) 0.5A × 16 +

PIO/SIO/SCON Extension Unit 0.3A × 1 + PIO Unit 0.2A × 7 = 9.7A ⇒ NG

(2) 200V Motor Power Supply Current Restrictions

Shown below is the restricting values for selecting calculation.

Item

Restricting Value for Selecting Calculation

200V Motor Power Supply (Single-phase)

1600W

200V Motor Power Supply (Three-phase)

2400W

The capacity necessary in the motor power supply should be figured out by [Total of control power

capacity of used units].

In the table of the capacity [Motor Power Supply] shown above, add the power capacity of all the actuator

motor wattages constructing the system and check that it does not exceed the restricting values of

current for selecting calculation described in Restrictions in Unit Connection.

However, apply the motor wattage for calculation for the actuators listed below.

Actuator Model Code

Motor Wattage for

Calculation

RCS3-CTZ5 120W

LSA-S6S□/S8S□/S8H□/N10S□ 300W / 1 Slider

LSA-S10SM/H8SM/H8HM/L15SM/N15SM/N15HM/N19SM 400W / 1 Slider

LSA-S10SS/S10HS/H8SS/H8HS/L15SS/N15SS/N15HS/N19SS

600W

LSA-W21S□、RCS3-CT8 800W / 1 Slider

Shown below is some examples for calculation.

[200V Motor Power Supply]

Example 5

One axis for each of actuator of 200W motor, actuator of 300W motor and actuator of 600W

moto

200W × 1 axis + 300W ×1 axis + 600W × 1 axis = 1100W

⇒

Single-phase OK, Three-phase OK

Example 6

RCS-CTZ5 × 1 axis, actuator of 200W motor × 7 axes

120W + 200W × 7 axes = 1520W⇒ Single-phase OK, Three-phase OK

Example 7

actuator of 200W motor × 6 axes, LSA-S10SM (Multiple Slider) × 1 axis

200W × 6 axes + 400W × 2 = 2000W ⇒ Single-phase NG, Three-phase OK

Example 8

actuator of 200W motor × 16 axes

200W × 16 axes = 3200W ⇒ Single-phase NG, Three-phase NG

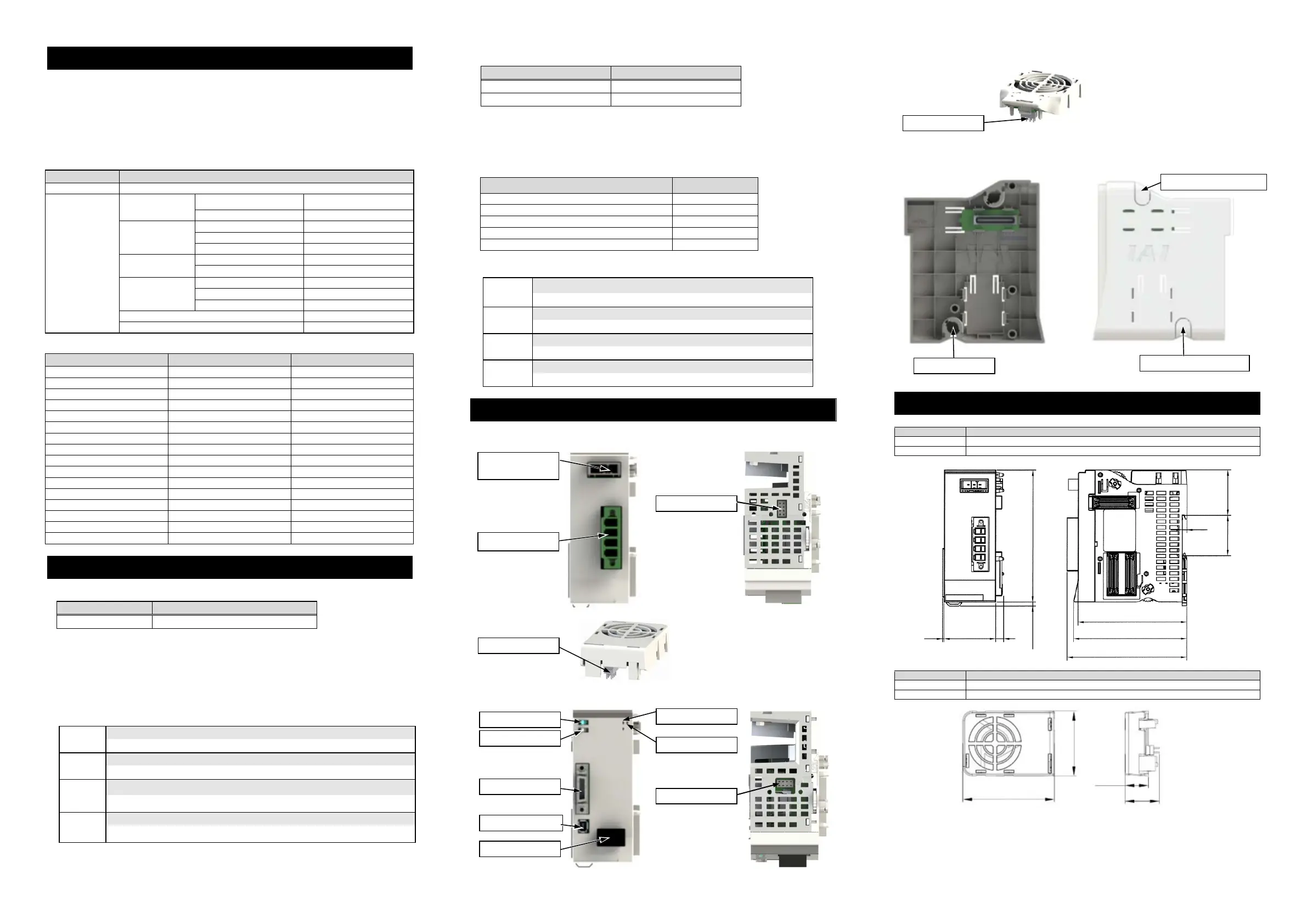

(1) 200V Power Supply Unit

Front Top

(2) Fan Unit

(3) 200V Driver Unit

Front Top

(4) Fan Unit for 200V Driver

(5) Terminal Unit for 200V

Left Side Right Side

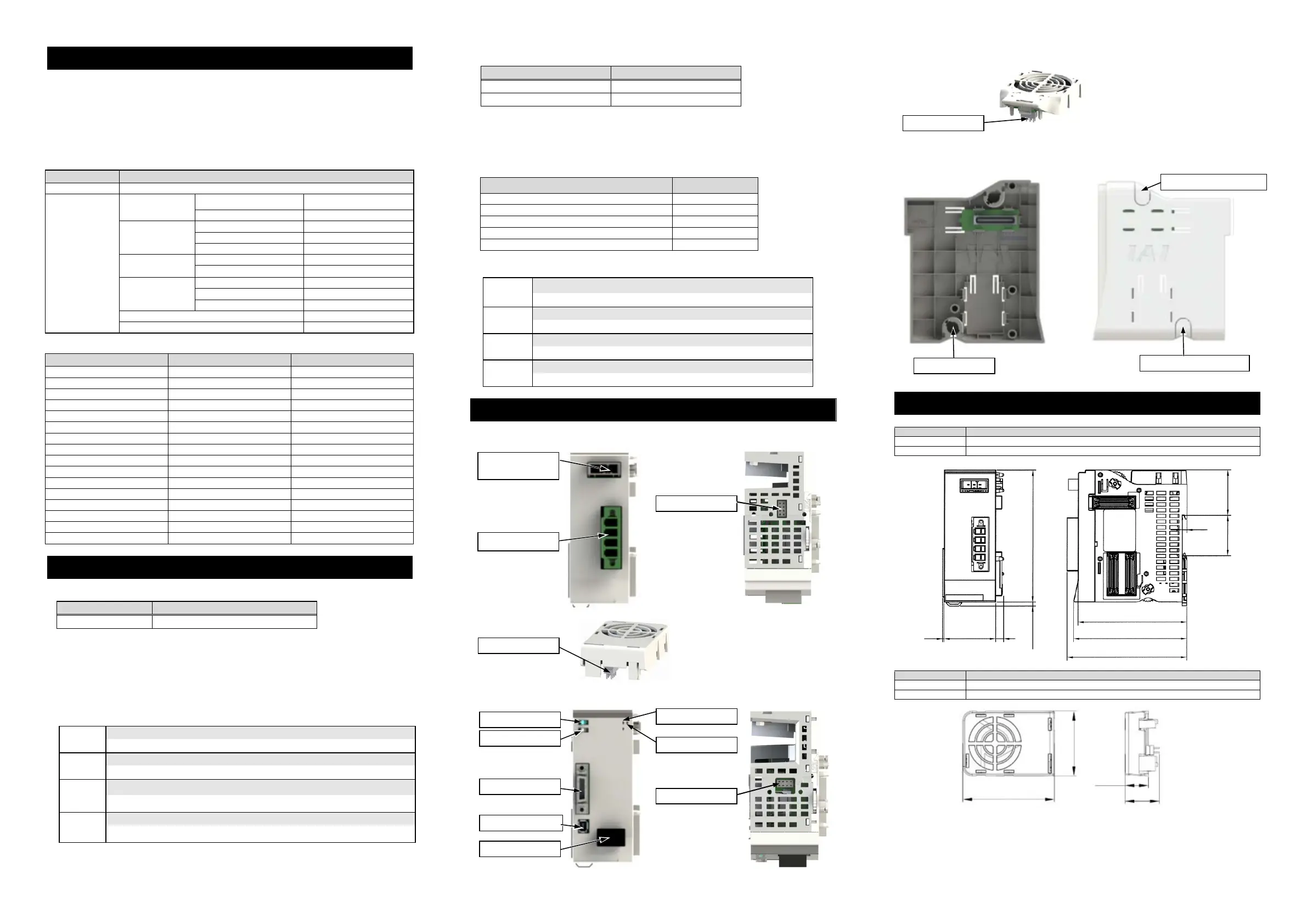

1. 200V Power Supply Unit

Item Specification

External Dimensions 45.2W × 115H × 95D [mm]

Mass Approx. 393g (fan unit weight excluded)

2. Fan Unit

Item Specification

External Dimensions 34.2W × 49H × 12.5D [mm]

Mass Approx. 16g

Names for Each Part

External Dimensions

External

Regenerative

Connector

200V AC

Input Connector

FAN Connector

FAN Connector

FAN Connector

Jog Switch

Brake Switch

Encoder Connector

Driver Stop Connector

SYS LED

T RUN LED

Motor Connector

Fan Connector

Bottom Parts for Terminal Unit

Upper Parts for Terminal Unit

34.2

49

12.5

18.4

115 3.5

7

45.2

39.6

4

35.2

95

1

98.8

104.5

Linked Connector

Loading...

Loading...