Surge absorber

R

C

+24V 0V

+24V 0V

+-

45.2 1

39.6

4

115

35.2

95

3.5

98.8

7

103.5

3. 200V Driver Unit

Item Specification

External Dimensions 45.2W × 115H × 95D [mm]

Mass Approx. 438g (fan unit weight excluded)

4. Fan Unit for 200V Driver Unit

Item Specification

External Dimensions 44.5W × 64H × 12.5D [mm]

Mass Approx. 20g

5. Terminal Unit for 200V

Item Specification

External Dimensions 12.6W × 115H × 95D [mm]

Mass Approx. 40g

6. Linking Units

Item Specification

External Dimensions (30 + 45.2 + 45.2 + 12.6) W × 115H × 95D [mm]

Mass Approx. 1,077g

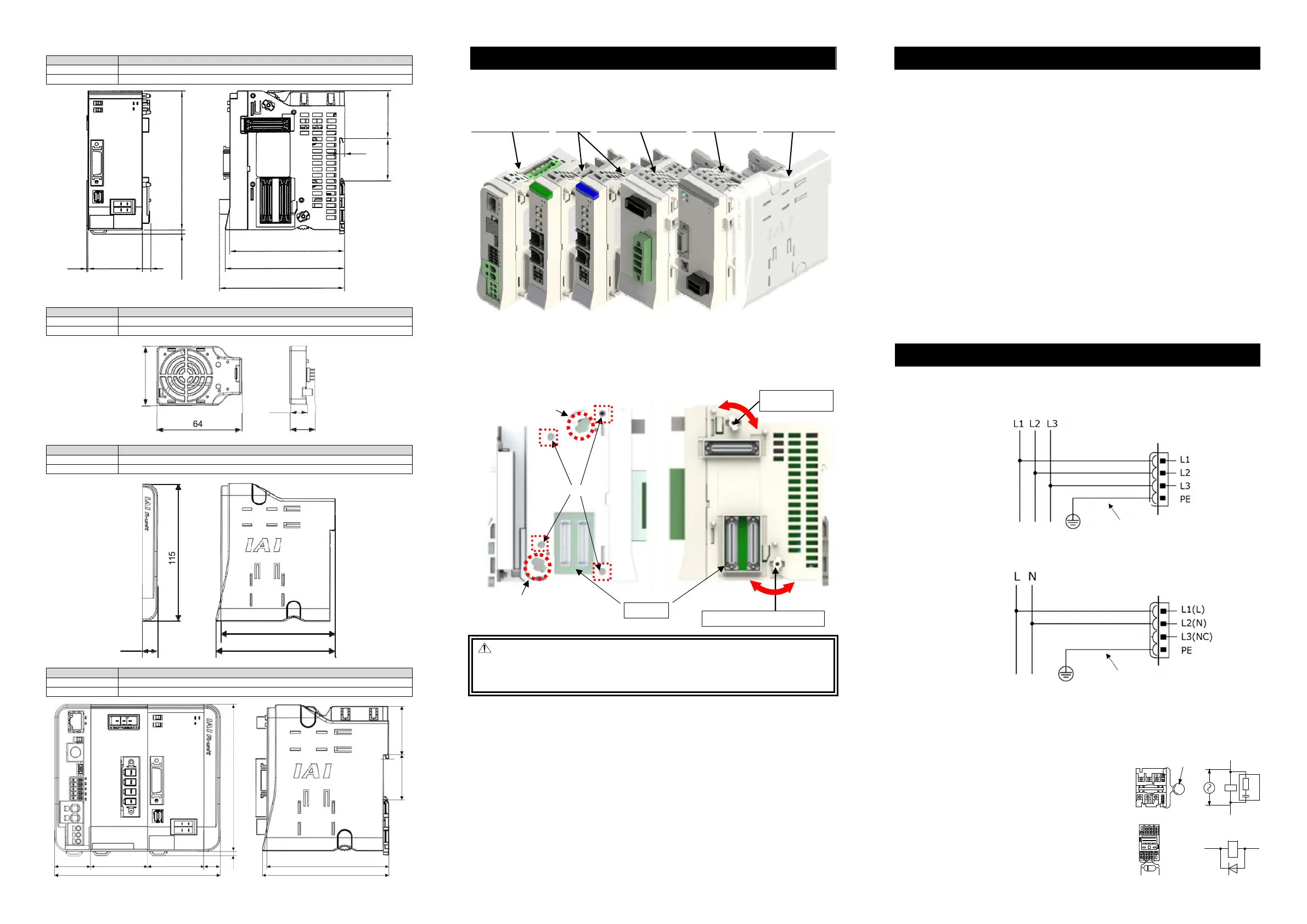

RCON/RSEL Systems possesses a locking structure with unit linking system. The 200V Power Supply Unit

is to be linked on the right of the 24V Driver Unit in the front view. The 200V Driver Units are to be linked on

the right of them for the necessary number of units, and the Terminal Unit for 200V come on the further right.

For the terminal unit, make sure to use the Terminal Unit for 200V enclosed to the 200V Power Supply Unit.

Gateway Unit (Left End) - Driver Unit - Power Supply Unit for 200V - Driver Unit for 200V - Terminal Unit for 200V

Unit should be linked in the process shown below. (Make sure it gets linked before connected to the DIN rails.)

1) Twist the operation parts of the link upper parts and the link bottom parts towards the panel side and

place them at the panel side end.

2) Adjust the position of two units so the link upper parts come to Point [A], link bottom parts to [B] and the

four positioning bosses to [C] and all the six points fit to each other.

3) Once positioning is done, firmly insert the connectors at two points.

4) Twist the operation parts of the link upper parts and the link bottom parts towards the rear side till they

make click feeling.

Danger: When there is a unit of 200V, make sure that the terminal unit on the right is the Terminal

Unit for 200V (RCON-GW-TRS) enclosed to the 200V Power Supply Unit. The Terminal

Unit for 24V has a structure that does not allow itself connected to the 200V units,

however, it could be forcefully inserted, which could cause fire on the connector as well as

damage on it.

Installation Environment

This product is capable for use in the environment of pollution degree 2

*1

or equivalent.

*1 Pollution Degree 2: Environment that may cause non-conductive pollution or transient conductive

pollution by frost (IEC60664-1)

1. Installation Environment

Do not use this product in the following environment.

Location where the ambient temperature is out of the range between 0 and 40C

Location where condensation occurs due to abrupt temperature changes

Location where relative humidity exceeds 85%RH

Location exposed to corrosive gases or combustible gases

Location exposed to significant amount of dust, salt or iron powder

Location subject to direct vibration or impact

Location exposed to direct sunlight

Location where the product may come in contact with water, oil or chemical droplets

Environment that blocks the air vent Refer to [Installation and Noise Elimination]

When using the product in any of the locations specified below, provide a sufficient shield.

Location subject to electrostatic noise

Location where high electrical or magnetic field is present

Location with the mains or power lines passing nearby

2. Storage and Preservation Environment

The storage and preservation environment should comply with the same standards as those for the

installation environment. However, the ambient temperature should be from -20 to 70°C and relative

humidity at 85%RH or below. In particular, when the machine is to be stored for a long time, pay close

attention to environmental conditions so that no condensation forms.

Unless specially specified, moisture absorbency protection is not included in the package when the machine

is delivered. In the case that the machine is to be stored and preserved in an environment where

condensation is anticipated, take the condensation preventive measures from outside of the entire package,

or directly after opening the package.

Installation and Noise Elimination

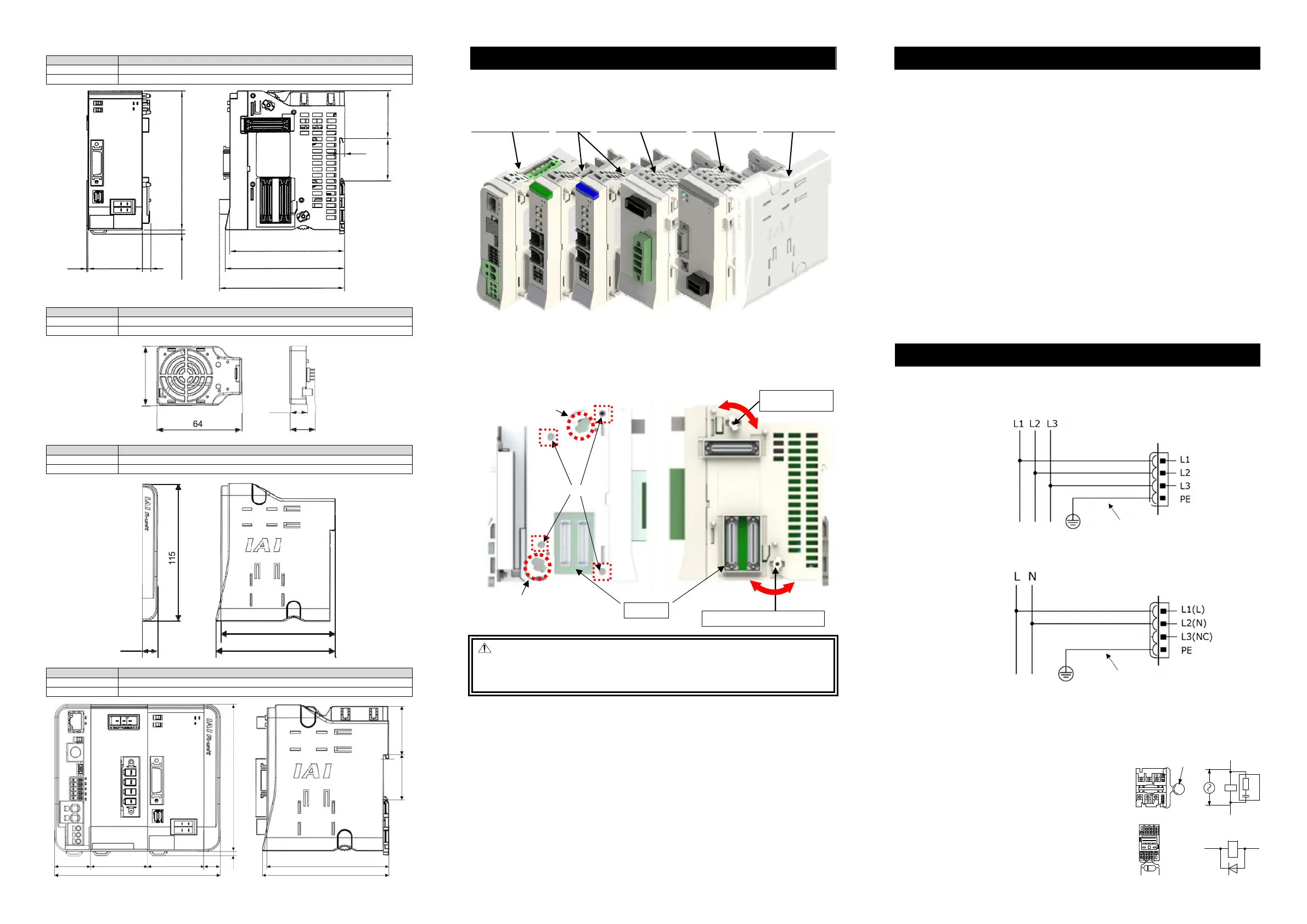

1. Protective Ground

For the grounding, the grounding resistance should be set to 100Ω or less (Class D grounding).

The wiring should apply a twist line or an annealed copper wire of 2.0mm

2

(AWG14) or more with an

isolation sheath with its rated temperature at 60°C or higher.

[200V

Three-phase Type]

[200V Single-phase Type]

2. Noise Elimination Grounding (Frame Ground)

Noise elimination grounding (frame ground) is conducted on the gateway unit side.

3. Precautions regarding wiring method

Separate I/O lines, communication lines and encoders, power source and supply lines from each other to

reduce the influence to each other.

4. Noise Sources and Elimination

Carry out noise elimination measures for electrical devices

on the same power path and in the same equipment.

The following are examples of measures to eliminate noise

sources.

1) AC solenoid valves, magnet switches and relays

[Measure] Install a Surge absorber parallel with the coil.

2) DC solenoid valves, magnet switches and relays

[Measure] Consider whether to attach a diode in parallel

to the coil or to use a diode built-in type.

Linking Units

Rear Side (Link)

Link Upper Parts

Operation Part

[C]

[A]

Link Bottom Parts Operation Part

[B]

Connector

Panel Side

(Unlink)

Rear Side

(Link)

Panel Side

(Unlink)

64

44.5

18.4

12.5

115

12.6

95

98.8

95

98.8

35.2

39.6

4

45.2

45.2

30

133

12.6

115

Motor Power Supply Connector

for 200V Motor Driving

Grounding resistance

at 100

Ω

or less

(Class D grounding)

St rand or annealed copper wire:

Connect with an eart h line of

2.0mm

2

(AWG14)ormore

Motor Power Supply Connector

for 200V Motor Driving

Grounding resistance

at 100

Ω

or less

(Class D grounding)

St rand or annealed copper wire:

Connect with an eart h line of

2.0mm

2

(AWG14) or more

Loading...

Loading...