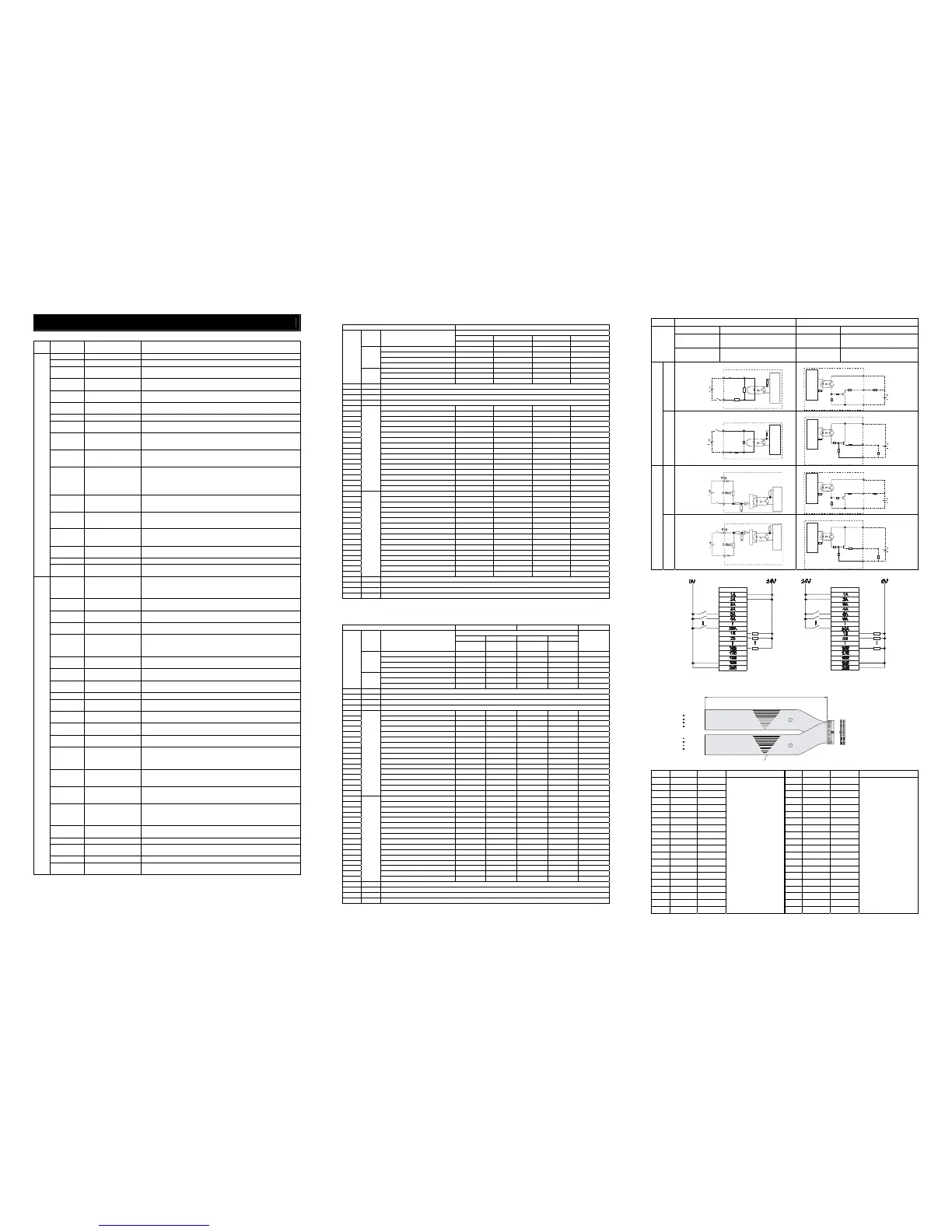

I/O Signal

Explanation of I/O Signal Functions

Category

Abbreviated

Code

Signal Name Contents of Functions

CSTR Start Signal (PTP Strobe) Starts moving toward the position set in Command Position No.

PC1 to PC256 Command Position No. To input position No. desired to move (binary input)

BKRL

Brake Compulsory

Release

To release the brake compulsorily

RMOD

Operation Mode

Changeover

Operation Mode can be changed over when MODE Switch on the controller

is on AUTO. The setting is AUTO when signal is OFF, and MANU when ON.

*STP Pause

Turn the signal off during operation to decelerate and stop. Turn the signal

ON to resume the operation.

RES Reset

Turn the signal on to reset the alarm. Also, it is possible to cancel the

residual operation if turning on during the pause (*STP is off).

SON Servo ON Turn on to turn the servo ON, and off to turn the servo OFF.

HOME Home return

Perform the home-return operation with the signal rising edge (OFF →

ON).

MODE Teaching Mode

Turn the signal on to set to the Teaching Mode, and off to cancel the

Teaching Mode. The mode will not be switched over unless CSTR, JOG+

and JOG− are all off and the actuator operation is stopped.

JISL Jog/Inching Changeover

Jog Operation can be performed with JOG+ and JOG− while this signal is

off.

Inching Operation is performed with JOG+ and JOG− when it is on.

JOG+

JOG−

Jog

Jog Operation is performed to positive direction by detecting ON edge of

JOG+ signal and to negative direction by JOG− signal while JISL signal is

off. The actuator will decelerate and stop if OFF edge is detected while in

each Jog Operation.

Inching Operation is performed while JISL signal is on.

PWRT Teaching

Write the current position to the indicated position if indicating the written

position and turn this signal on for more than 20ms during the Teaching

Mode.

CLBR

(Specified only

for CA)

Loadcell Calibration

Command

Turn this signal on for more than 20ms to perform calibration of loadcell.

ST0 to ST6 Start Signal 0 to 6

The actuator moves to the commanded position with this signal on during

the electromagnetic valve mode.

(CSTR signal is not required)

TL Torque Limit Select

Puts torque limitation to the motor with the signal on and the value set to

the parameter.

DCRL Deviation Counter Clear Clears the deviation count with the signal on.

Input

CSTP Compulsory Stop

Performs compulsory stop of the actuator. Turn the signal on to decelerate

and stop the actuator and turns the servo off.

PEND/INP Position Completion

Turns on in the positioning band range after actuator operation. PEND

signal will not turn off once it turns on until the next operation even if the

actuator goes off the range of positioning band. INP will turn off. PEND

and INP can be switched over by the parameter.

PM1 to PM256 Completion Position No.

Outputs (binary output) the position No. that is reached at the same time

the positioning is complete.

HEND Home Return Completion

Turns on when home-return operation is complete. It will be kept on unless

the home position is lost.

ZONE1, 2 Zone

Turns on if the current actuator position is within the range set to the

parameter.

PZONE Position Zone

Turns on when the current actuator position gets into the range set to the

position data during the move towards the position. It can be utilized

together with ZONE 1, however, PZONE is effective only when moving

towards the set position.

RMDS Operation Mode Output

Outputs the operation mode status. It turns on when the controller is on

Manual Mode.

*ALM Alarm

Turns on when controller in normal condition, and off when alarm is

generated.

MOVE While in Operation

Turns on during the actuator is moving (including home-return operation

and pressing operation).

SV Servo ON status

Turns on when the servo is on.

*EMGS Emergency Stop Output

Turns on when the controller emergency stop is cancelled, and off during

the emergency stop (regardless of alarms).

MODES Teaching Mode Output

Turns on when it turns to the Teaching Mode by MODE signal input. It is off

in the normal mode.

WEND Writing Complete

Turns on after the writing by PWRT signal is complete in the Teaching

Mode. This signal turns off if PWRT signal is turned off.

PE0 to PE6 Current Position Number

Turns on when moving to the target position is complete in

Electromagnetic Valve Mode.

LS0 to LS2 Limit Switch Output

Turns on when the current actuator position is within the range of

positioning band (±) of the target position. It is output even before the

movement command and the servo is off if the home-return operation is

completed.

CEND

(Specified only

for CA)

Loadcell Calibration

Complete

Turns on after loadcell calibration is complete. This signal turns off if CLBR

signal is turned off.

*BALM

Warning for Absolute

Battery Voltage Drop

Turns on when the battery voltage for the absolute type actuator is within

the normal voltage range. Replace the battery if it is turned off. (this signal

is always on for the incremental type actuator.)

LOAD

Load Output Judgment

Signal

Outputs when current exceeds the value set to “threshold” within range of

position data “ZONE+” or “ZONE−” during the pressing operation.

Utilize this signal for a judgment of a press-fitting process being properly

performed, etc.

TRQS Torque Level Output

Outputs when current of motor reaches the value set to “threshold” by the

slider (or rod) being hit to an obstacle during the pressing movement.

ALM1 to 8 Alarm Code Output Outputs the alarm code when an alarm is generated

TLR Torque Limit Restricted

Turns on when torque reaches the limit while in torque restriction (TL

signal is on).

PWR System Standby Turns on when the controller is able to be controlled.

Output

*ALML

Light Error Alarm

(only for SCON-CA)

This turns on when any of the absolute battery alarm, overload alarm or

message level alarm is occurred.

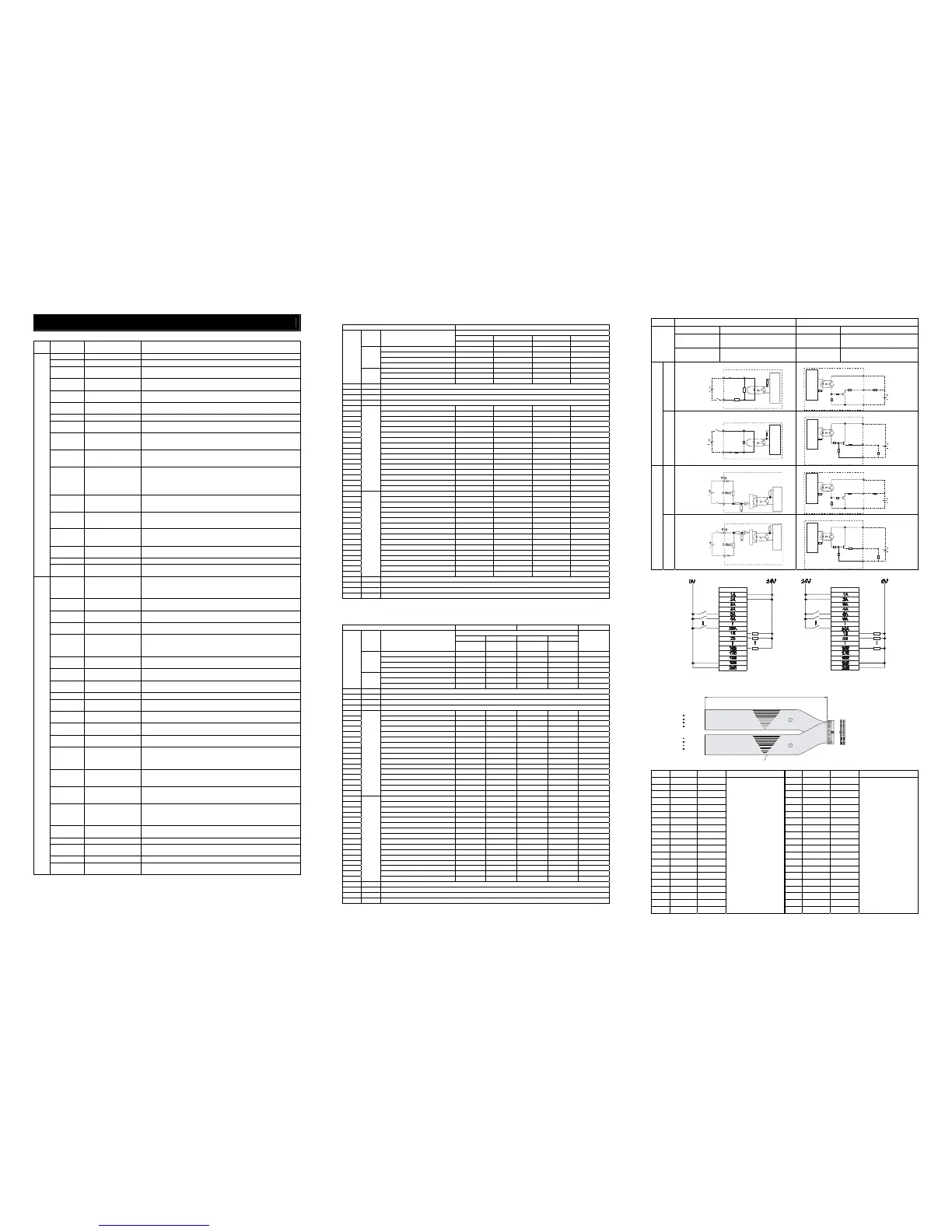

Signal Assignment for Each Mode

The signal assignment of I/O flat cable by the PIO pattern is as shown below. Follow the following table to connect the external equipment (such as PLC).

Corresponding Type All Types

Selection in Parameter No. 25 (PIO Pattern)

0 1 2 3

Category

PIO Functions

Positioning mode Teaching mode 256-point mode 512-point mode

Number of Positioning Points 64 points 64 points 256 points 512 points

Jog Signal × { × ×

Teaching Signal (Current Position Writing)

× { × ×

Input

Brake Release { × { {

Signal during Operation { { × ×

Zone Signal { × × ×

Pin No.

Output

Position Zone Signal { { { ×

1A 24V P24

2A 24V P24

3A − −

4A − −

5A IN0 PC1 PC1 PC1 PC1

6A IN1 PC2 PC2 PC2 PC2

7A IN2 PC4 PC4 PC4 PC4

8A IN3 PC8 PC8 PC8 PC8

9A IN4 PC16 PC16 PC16 PC16

10A IN5 PC32 PC32 PC32 PC32

11A IN6 − MODE PC64 PC64

12A IN7 − JISL PC128 P128

13A IN8 − JOG+ − PC256

14A IN9 BKRL JOG− BKRL BKRL

15A IN10 RMOD RMOD RMOD RMOD

16A IN11 HOME HOME HOME HOME

17A IN12 *STP *STP *STP *STP

18A IN13 CSTR CSTR/PWRT CSTR CSTR

19A IN14 RES RES RES RES

20A

Input

IN15 SON SON SON SON

1B OUT0 PM1 (ALM1) PM1 (ALM1) PM1 (ALM1) PM1 (ALM1)

2B OUT1 PM2 (ALM2) PM2 (ALM2) PM2 (ALM2) PM2 (ALM2)

3B OUT2 PM4 (ALM4) PM4 (ALM4) PM4 (ALM4) PM4 (ALM4)

4B OUT3 PM8 (ALM8) PM8 (ALM8) PM8 (ALM8) PM8 (ALM8)

5B OUT4 PM16 PM16 PM16 PM16

6B OUT5 PM32 PM32 PM32 PM32

7B OUT6 MOVE MOVE PM64 PM64

8B OUT7 ZONE1 MODES PM128 PM128

9B OUT8 PZONE/ZONE2 PZONE/ZONE1 PZONE/ZONE1 PM256

10B OUT9 RMDS RMDS RMDS RMDS

11B OUT10 HEND HEND HEND HEND

12B OUT11 PEND PEND/WEND PEND PEND

13B OUT12 SV SV SV SV

14B OUT13 *EMGS *EMGS *EMGS *EMGS

15B OUT14 *ALM *ALM *ALM *ALM

16B

Output

OUT15 *BALM

*BALM *BALM *BALM

17B − −

18B − −

19B 0V N

20B 0V N

(Note) “*” in codes above shows the signal of the active low.

PM1 to PM8 indicate the alarm binary code output signal when an alarm is generated.

(Reference) Signal of Active Low

Signal with “*” expresses the signal of active low. A signal of active low is a signal that the input signal is processed when it is

turned off, output signal is ordinary on while the power is on, and turns off when the signal is output.

Corresponding Type All Types CA Type All Types

Selection in Parameter No. 25 (PIO Pattern)

4 5 6 7

Category

PIO Functions

Electromagnetic

Valve Mode 1

Electromagnetic

Valve Mode 2

Force Control

Mode 1

Force Control

Mode 2

Pulse Train

Control Mode

Number of Positioning Points 7 points 3 points 32 points 5 points −

Jog Signal × × × × ×

Teaching Signal (Current Position Writing)

× × × × ×

Input

Brake Release { { { { {

Signal during Operation × × × × ×

Zone Signal { { × × {

Pin No.

Output

Position Zone Signal { { { { ×

1A 24V P24

2A 24V P24

3A − −

4A − −

5A IN0 ST0 ST0 PC1 ST0 SON

6A IN1 ST1 ST1 (JOG+) PC2 ST1 RES

7A IN2 ST2 ST2

*1

PC4 ST2 HOME

8A IN3 ST3 − PC8 ST3 TL

9A IN4 ST4 − PC16 ST4 CSTP

10A IN5 ST5 − − − DCLR

11A IN6 ST 6 − − − BKRL

12A IN7 − − − − RMOD

13A IN8 − − CLBR CLBR −

14A IN9 BKRL BKRL BKRL BKRL −

15A IN10 RMOD RMOD RMOD RMOD −

16A IN11 HOME − HOME HOME −

17A IN12 *STP − *STP *STP −

18A IN13 − − CSTR − −

19A IN14 RES RES RES RES −

20A

Input

IN15 SON SON SON SON −

1B OUT0 PE0 LS0 PM1(ALM1) PE0 PWR

2B OUT1 PE1 LS1(TRQS) PM2(ALM2) PE1 SV

3B OUT2 PE2 LS2

*1

PM4(ALM4) PE2 INP

4B OUT3 PE3 − PM8(ALM8) PE3 HEND

5B OUT4 PE4 − PM16 PE4 TLR

6B OUT5 PE5 − TRQS TRQS *ALM

7B OUT6 PE6 − LOAD LOAD *EMGS

8B OUT7 ZONE1 ZONE1 CEND CEND RMDS

9B OUT8

PZONE/ZONE2 PZONE/ZONE2 PZONE/ZONE1 PZONE/ZONE1

ALM1

10B OUT9 RMDS RMDS RMDS RMDS ALM2

11B OUT10 HEND HEND HEND HEND ALM4

12B OUT11 PEND − PEND PEND ALM8

13B OUT12 SV SV SV SV −/*ALML

*2

Loading...

Loading...