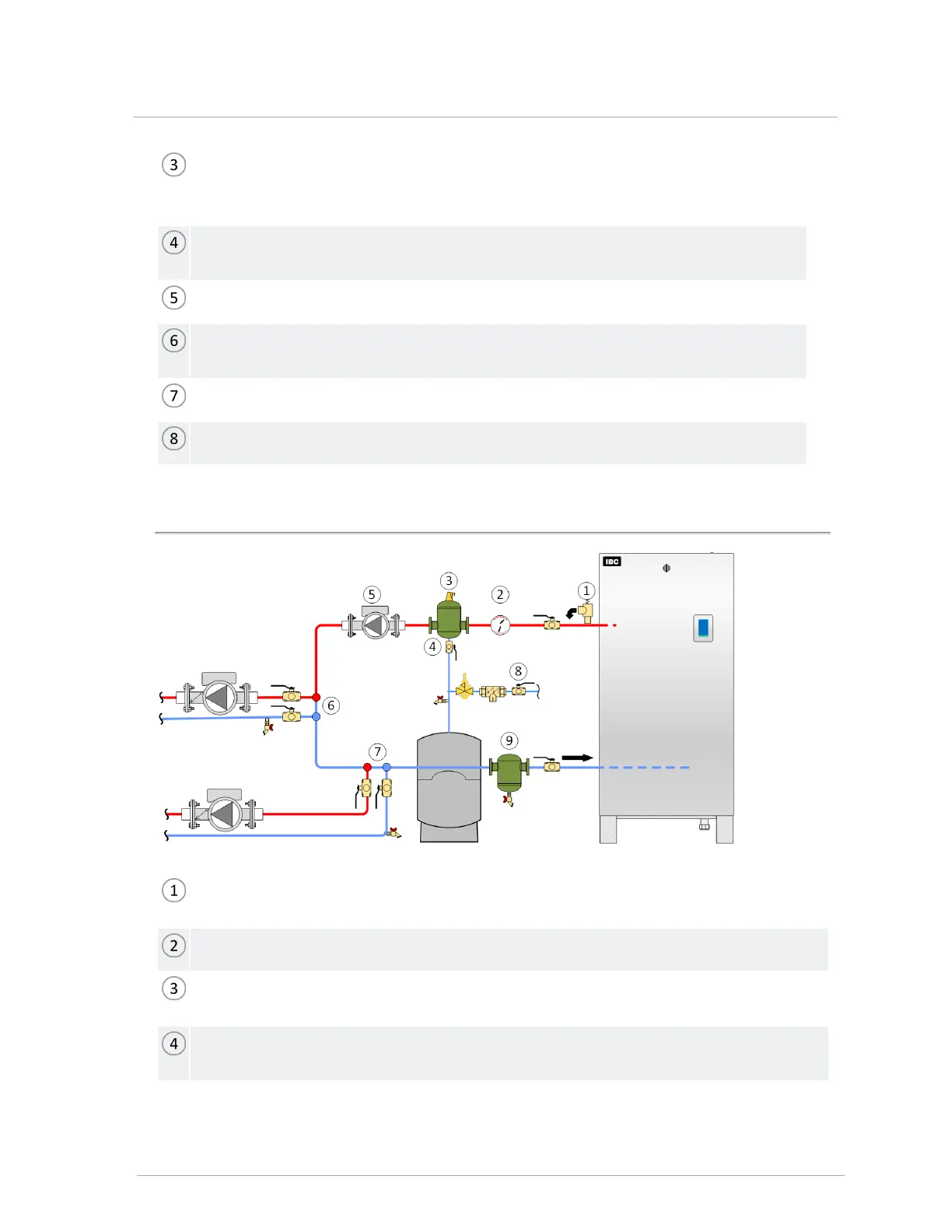

Hydraulic separator (low-loss header) provides primary/secondary hydraulic separation, a

microbubble air eliminator and a dirt separator. Air eliminator is installed at the most effective

point, where the fluid is at the highest temperature and lowest pressure.

Secondary pumps to multiple loads or zones. All receive identical temperatures. Note integrated

check valves.

Return lines from loads.

Expansion tank connection (point of no pressure change)should be on the suction side of the

circulator.

Primary pump or boiler circulator into connection at rear of boiler.

Fill station with isolation valve closed, or fill tank.

Pressure relief valve (field-supplied): no isolation valve is permitted between the boiler and relief

valve.

Tridicator or external pressure and temperature gauge (field-supplied).

Microbubble air eliminators are best installed where the fluid is at the highest temperature and

lowest pressure.

Expansion tank connection (point of no pressure change) should be on the suction side of the

circulator.

Loading...

Loading...