3. Timehowmanysecondsittakesthesmallestdialonthegas NOTE:Ifmeterusesa2cubicfootdial,divideresults(seconds)by

metertomakeonecompleterevolution.RefertoExample. two.

4. Relightallappliancesandensureallpilotsareoperating.

!i!i!i!!ii !i!i ilii!iiii!!

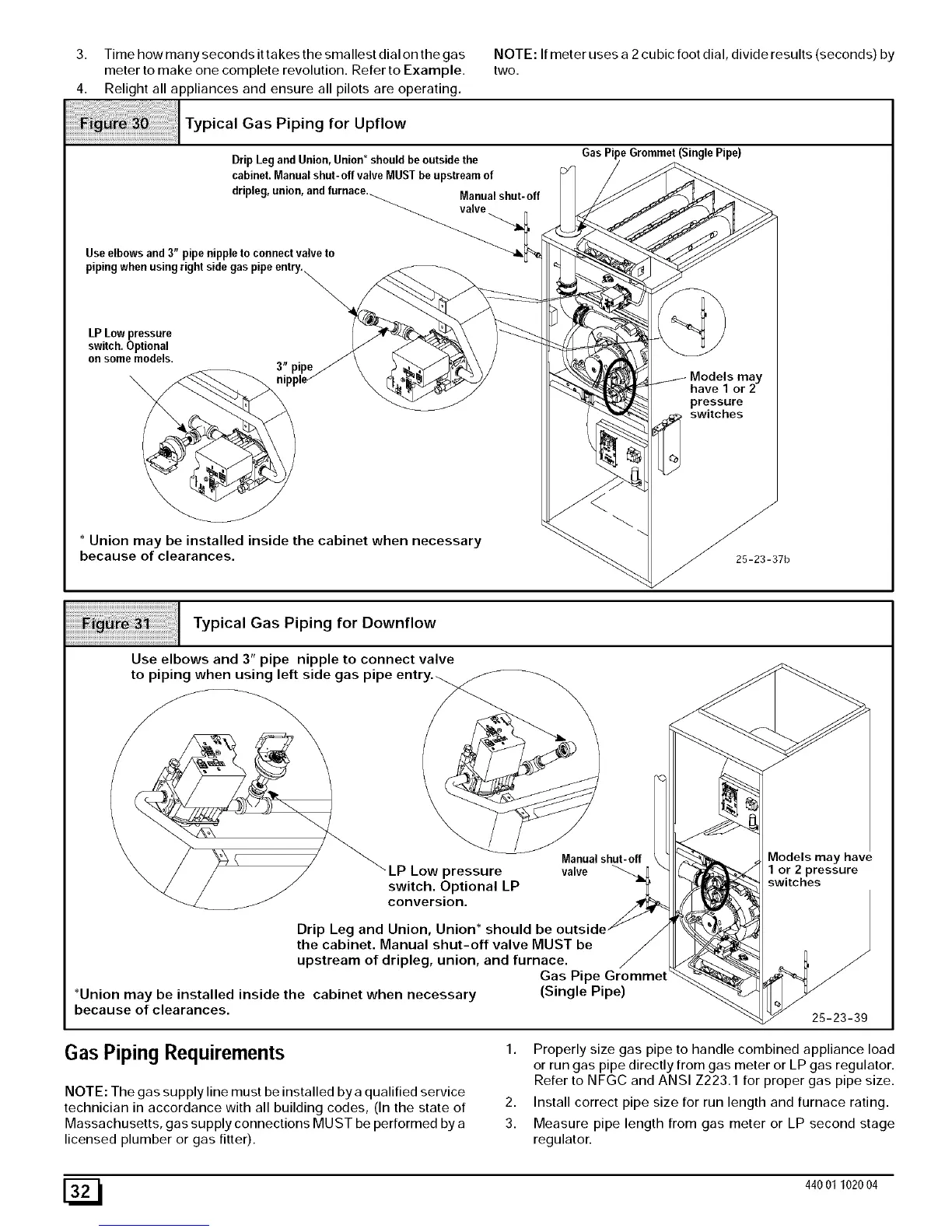

Typica,GasPipiog,orU .ow

Drip Legand Union,Union* shouldbeoutsidethe GasPipe Grommet(SinglePipe)

cabinet.Manualshut-off valveMUSTbe upstreamof "_ _Y / _//_

dripleg,union, andfurnace. Manualshut-off

Useelbows and3" pipenippleto connectvalveto _

on some models. . / \ /_ _ \ /

have 1 or 2

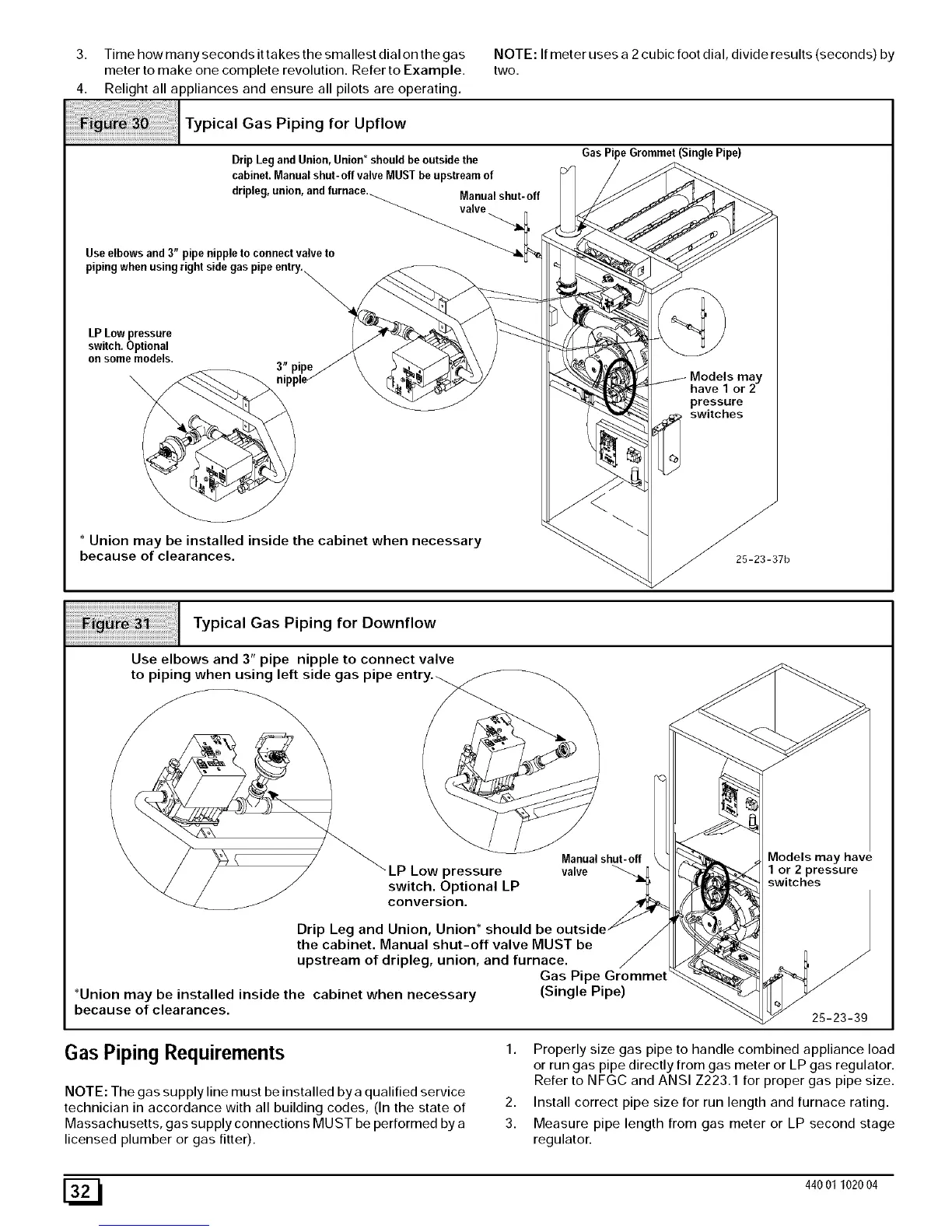

I Typical Gas Piping for Downflow

Use elbows and 3" pipe nipple to connect valve

to piping when using left side gas pipe

LP Low pressure

switch. Optional LP

conversion.

Manualshut- off

valve

Drip Leg and Union, Union* should be

the cabinet. Manual shut-off valve MUST be

upstream of dripleg, union, and furnace.

Gas Pipe Grommet

*Union may be installed inside the cabinet when necessary (Single Pipe)

because of clearances.

4odels may have

1 or 2 pressure

switches

25-23-39

Gas Piping Requirements

NOTE: The gas supply line must be installed bya qualified service

technician in accordance with all building codes, (In the state of

Massachusetts, gas supply connections MUST be performed by a

licensed plumber or gas fitter).

1. Properly size gas pipe to handle combined appliance load

or run gas pipe directly from gas meter or LP gas regulator.

Refer to NFGC and ANSI Z223.1 for proper gas pipe size.

2. Install correct pipe size for run length and furnace rating.

3. Measure pipe length from gas meter or LP second stage

regulator.

[_1 440 01 1020 04

Loading...

Loading...