Consignes sp6ciales pour rinstallation de ventillation au

Canada

Uinstallation faite au Canada dolt se conformer aux exigences du

code CSA B149. Ce syst_me de ventillation dolt se composer de

tuyaux, raccords, ciments et appr_ts conformes au ULC S636. La

tuyauterie de ventillation des gaz, ses accessoires, le terminal

concentrique mural ainsi que I'ensemble du drain de condensat

exterieur ont et6 certifies ULCS 636 pour I'application des

composantes Royal Pipe, IPEX PVC qui sont certifiees & ce

standard. Au Canada, I'appr_t et le ciment doivent _tre du m_me

fabricant que le systeme d'evacuation. Uappr_t GVS-65 (Purple)

et le ciment-solvant GVS-65 doivent _tre utilise avec les Royal

Pipe. Systeme IPEX 636, appr_t PVC/CPVC, Purple pour

evacuation des gaz de combustion et systeme IPEX 636(1)'=,

ciment PVC pour evacuation des gaz de combustion, cots classe

IIA, 65 deg C. doivent _tre utitises avec le systeme d'evacuation

IPEX 636 - Ne pas combiner I'appr_t et le ciment d'un

manufacturier avec un systeme d'evacuation d'un manufacturier

different.

Bien suivre les indications du manufacturier Iors de t'utilisation de

I'appr_t et du ciment et ne pas utiliser ceux-ci si la date d'expiration

est atteinte.

Uoperation securitaire, tel que definit par ULC S636, du systeme

de ventilation est base sur les instructions d'installation suivantes,

ainsi que I'usage approprie de I'appr_t et ciment. Tout arret feu et

solin de toit utilises avec ce systeme doivent _tre des materiaux

listes UL. L'acceptation du standard Canadien CSA B419 est

directement relie & I'installation conforme aux instructions ci- haut

mentionnees. Le standard Canadien recommande I'inspection

par un personel qualifie et ce, une fois par annee.

Les autoritees ayant juridiction (inspecteurs de gas, inspecteurs

en b&timents, departement des incendies, etc) devraient _tre

consultees avant I'instatlation afin de determiner si un permis est

requis.

On the Dual Certified furnace, the vent and combustion air pipes

attach to the furnace through the top panel for the upflow and

horizontal installations. For the downflow installation, the vent and

combustion air pipes attach to the furnace through the alternate

locations on the furnace side panels.

Note: On the Direct Vent furnace, the vent pipe attaches to the

furnace through the side panels. The combustion air pipe attaches

to the top panel or to the alternate location on the side panel.

On the Single Pipe furnace, the vent pipe attaches to the furnace

through the furnace side panels.

Note: Repositioning of the combustion blower is required for the

vent pipe connection to the furnace through the "right side" panel.

See "Vent and Combustion Air Piping" section for further details.

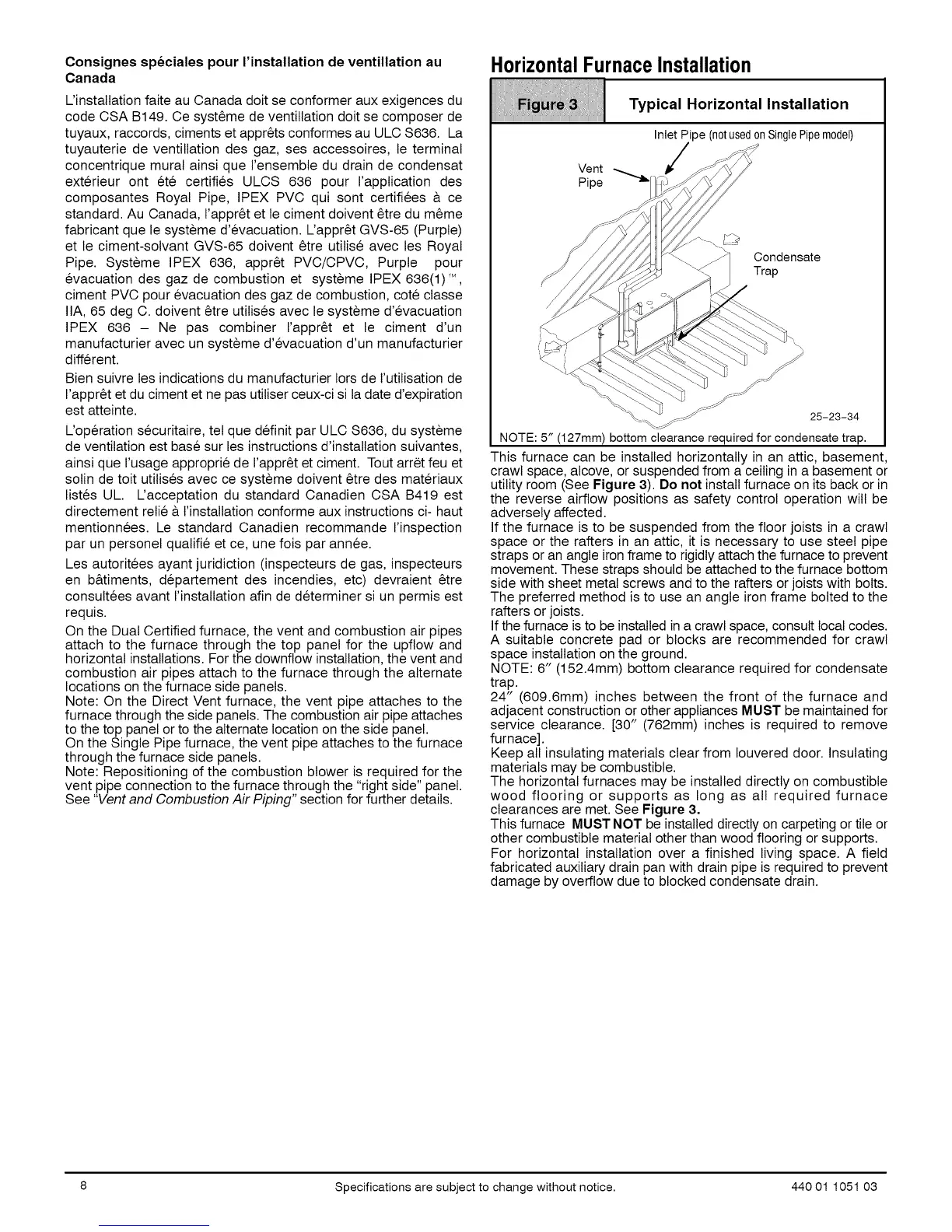

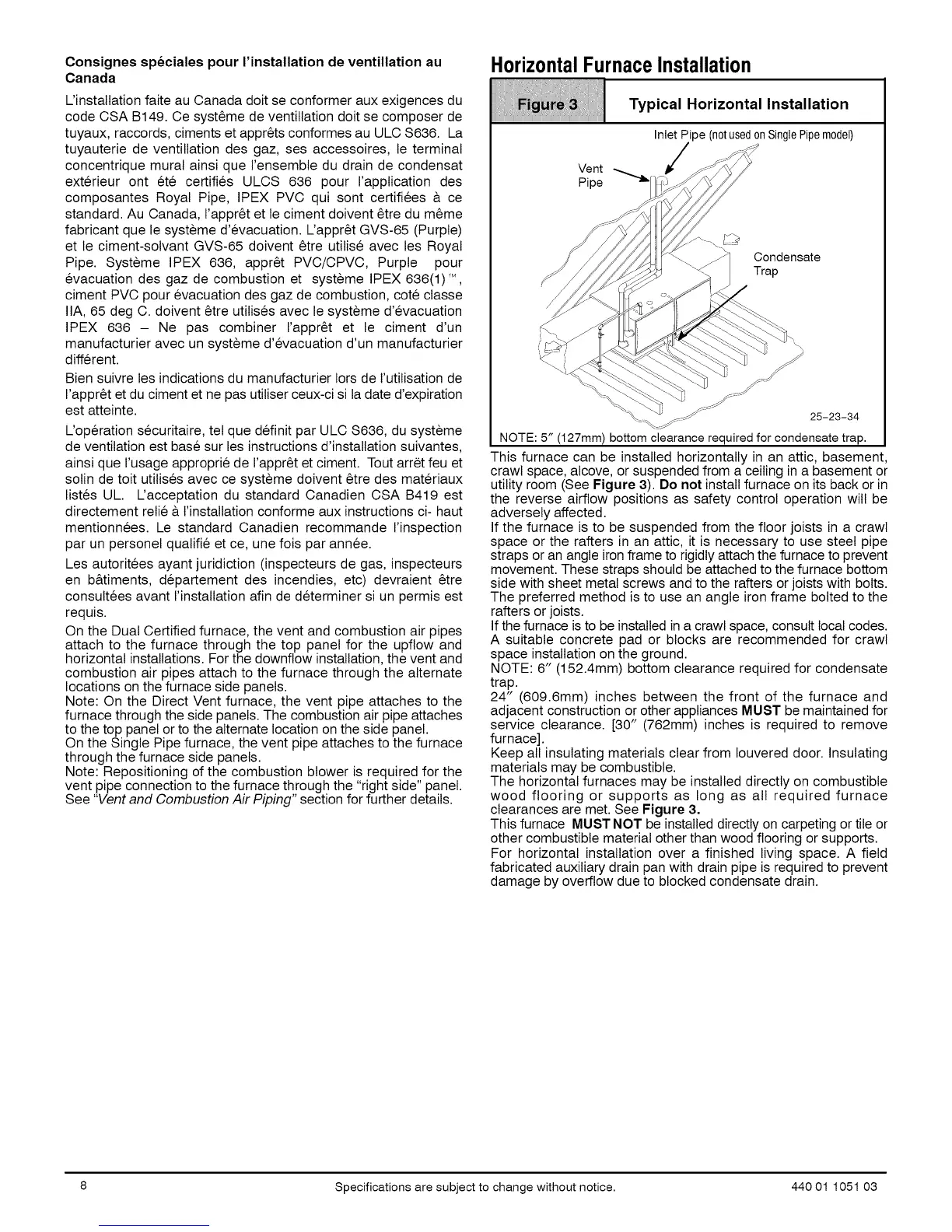

HorizontalFurnaceInstallation

Typical Horizontal Installation

Inlet Pipe (notusedonSinglePipemodel)

Vent

Pipe

_'] Condensate

__ Trap

\h --4:

25-23-34

NOTE: 5" (127mm) bottom clearance required for condensate trap.

This furnace can be installed horizontally in an attic, basement,

crawl space, alcove, or suspended from a ceiling in a basement or

utility room (See Figure 3). Do not install furnace on its back or in

the reverse airflow positions as safety control operation will be

adversely affected.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to rigidly attach the furnace to prevent

movement. These straps should be attached to the furnace bottom

side with sheet metal screws and to the rafters or joists with bolts.

The preferred method is to use an angle iron frame bolted to the

rafters or joists.

If the furnace is to be installed in a crawl space, consult local codes.

A suitable concrete pad or blocks are recommended for crawl

space installation on the ground.

NOTE: 6" (152.4mm) bottom clearance required for condensate

trap.

24" (609.6mm) inches between the front of the furnace and

adjacent construction or other appliances MUST be maintained for

service clearance. [30" (762mm) inches is required to remove

furnace].

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace

clearances are met. See Figure 3.

This furnace MUST NOT be installed directly on carpeting or tile or

other combustible material other than wood flooring or supports.

For horizontal installation over a finished living space. A field

fabricated auxiliary drain pan with drain pipe is required to prevent

damage by overflow due to blocked condensate drain.

8 Specifications are subject to change without notice. 440 01 1051 03

Loading...

Loading...