Example

Natural Gas No. of Seconds Time Per Cubic BTU Per

BTU Content Per Hour Foot in Seconds Hour

1,000 3,600 48 75,000

1,000 x 3,600 ÷ 48 = 75,000 BTUH

3. Relight all appliances and ensure all pilots are operating.

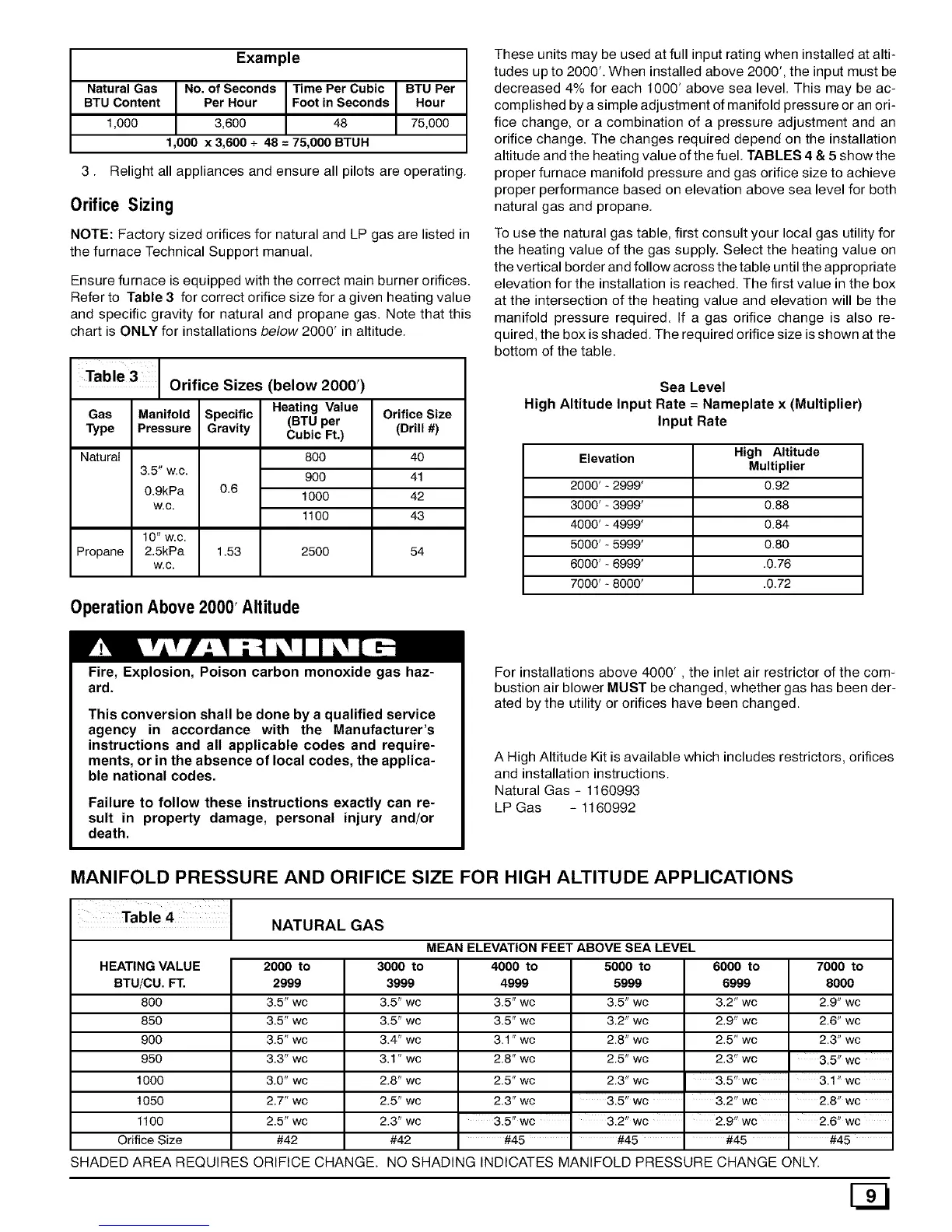

Orifice Sizing

NOTE: Factory sized orifices for natural and LP gas are listed in

the furnace Technical Support manual.

Ensure furnace is equipped with the correct main burner orifices.

Refer to Table 3 for correct orifice size for a given heating value

and specific gravity for natural and propane gas. Note that this

chart is ONLY for installations below 2000' in altitude.

Table 3

Orifice Sizes (below 2000')

Heating Value

Gas Manifold Specific (BTU per

Type Pressure Gravity Cubic Ft.)

Natural 800

3.5" w.c. 900

0.9kPa 0.6

1000

W.C.

1100

10" W.C.

Propane 2.5kPa 1.53 2500

w.c.

Orifice Size

(Drill #)

40

41

42

43

54

OperationAbove 2000' Altitude

Fire, Explosion, Poison carbon monoxide gas haz-

ard.

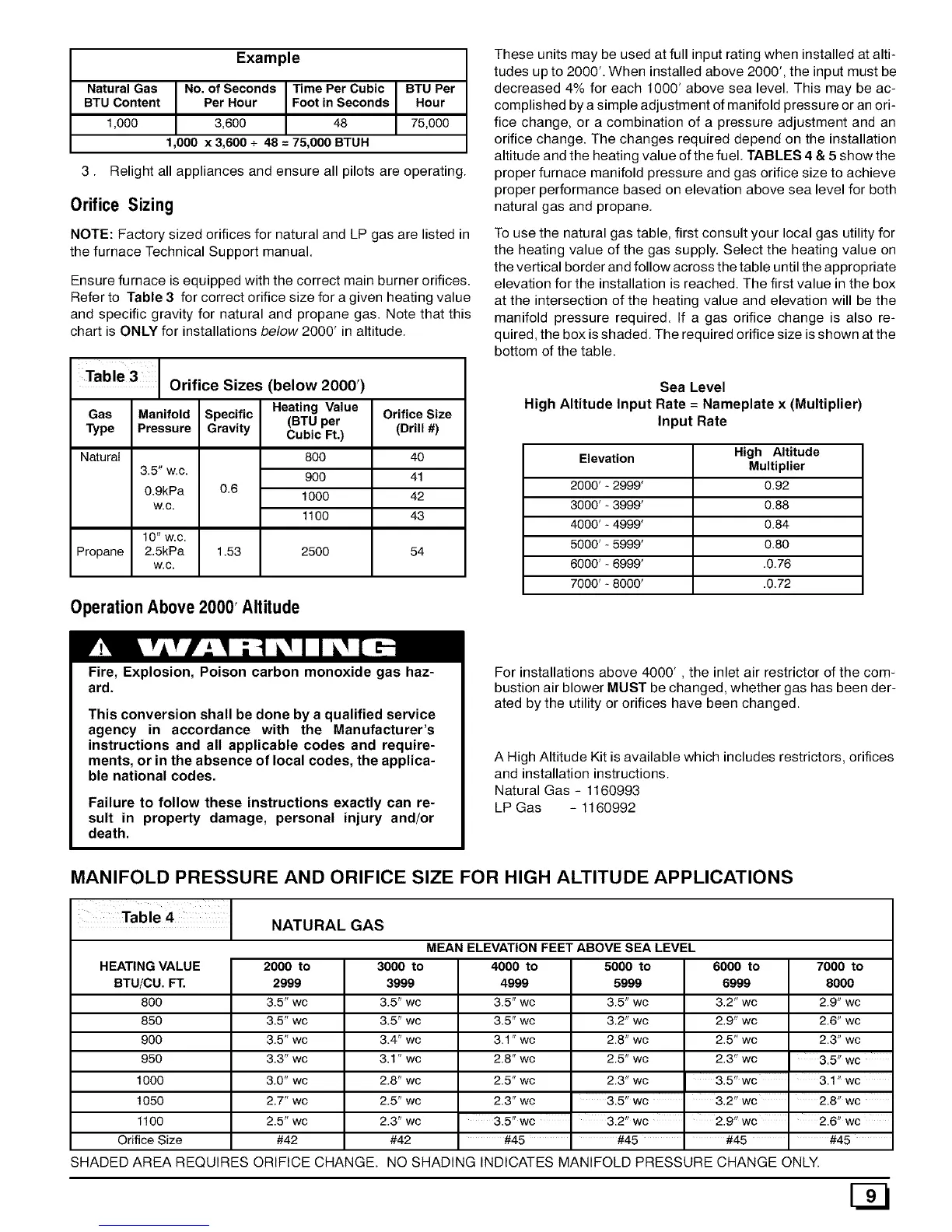

These units may be used at full input rating when installed at alti-

tudes up to 2000'. When installed above 2000', the input must be

decreased 4% for each 1000' above sea level. This may be ac-

complished by a simple adjustment of manifold pressure or an ori-

fice change, or a combination of a pressure adjustment and an

orifice change. The changes required depend on the installation

altitude and the heating value of the fuel. TABLES 4 & 5 show the

proper furnace manifold pressure and gas orifice size to achieve

proper performance based on elevation above sea level for both

natural gas and propane.

To use the natural gas table, first consult your local gas utility for

the heating value of the gas supply. Select the heating value on

the vertical border and follow across the table until the appropriate

elevation for the installation is reached. The first value in the box

at the intersection of the heating value and elevation will be the

manifold pressure required. If a gas orifice change is also re-

quired, the box is shaded. The required orifice size is shown at the

bottom of the table.

Sea Level

High Altitude Input Rate = Nameplate x (Multiplier)

Input Rate

Elevation High Altitude

Multiplier

2000'-2999' 0.92

3000'-3999' 0.88

4000'-4999' 0.84

5000'-5999' 0.80

6000'-6999' .0.76

7000'-8000' .0.72

This conversion shall be done by a qualified service

agency in accordance with the Manufacturer's

instructions and all applicable codes and require-

ments, or in the absence of local codes, the applica-

ble national codes.

Failure to follow these instructions exactly can re-

sult in property damage, personal injury and/or

death.

For installations above 4000', the inlet air restrictor of the com-

bustion air blower MUST be changed, whether gas has been der-

ated by the utility or orifices have been changed.

A High Altitude Kit is available which includes restrictors, orifices

and installation instructions.

Natural Gas - 1160993

LP Gas - 1160992

MANIFOLD PRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDE APPLICATIONS

Table 4

HEATING VALUE

BTU/CU. FT.

800

850

900

950

t 000

t 050

1100

Orifice Size

NATURAL GAS

2000 to

2999

3.5" wc

3.5" wc

3.5" wc

3.3" wc

3.0" wc

2.7" wc

2.5" wc

#42

MEAN ELEVATION FEET ABOVE SEA LEVEL

3000 to 4000 to

3999 4999

3.5" wc 3.5" wc

3.5" wc 3.5" wc

3.4" wc 3.1" wc

3.1" wc 2.8" wc

2.8" wc 2.5" wc

2.5" wc 2.3" wc

2.3" wc

#42

;HADED AREA REQUIRES ORIFICE CHANGE.

5000 to

5999

3.5" wc

3.2" wc

2.8" wc

2.5" wc

2.3" wc

3.5" wc

6000 to

6999

3.2" wc

2.9" wc

2.5" wc

2.3" wc

7000 to

8000

2.9" wc

2.6" wc

2.3" wc

3.5" wc

3.5" wc ' 3.1" wc

3.2" wc • 2.8" wc

3.5" wc " 3.2" wc 2.9" wc • 2.6" wc

#45 " #45 " #45 " #45

NO SHADING INDICATES MANIFOLD PRESSURE CHANGE ONLY.

Loading...

Loading...