MAINTENANCE 9VX3

5. Swing Relief Valve Pressure Measuring and Adjusting Procedure

Procedures Note

Conditions

Measuring

procedures

Adjusting

procedures

1. Engine speed : Low idle

2. Hyd. oil Temp. : 50±5°C

3. Install of pressure gauge : Install the

pressure gauge (29.4 MPa) to the P2

gauge port.

1. Align the upper structure with the track

and engage the swing lock pin and

lower the bucket to the ground.

2. Stop the engine. Remove the fill plug

on the hydraulic tank. Install the

pressure gauge on the control valve to

P2 gauge port. Install the fill plug.

3. Start the engine, move the engine

throttle lever to low idle. Move the

swing lever right or left fully stroke to

hold it, and measure the pressure.

4. Stop the engine. Remove the fill plug

on the hydraulic tank.

5. Remove the pressure gauge. Apply

pipe sealant to the plug. Install the fill

plug on the hydraulic tank.

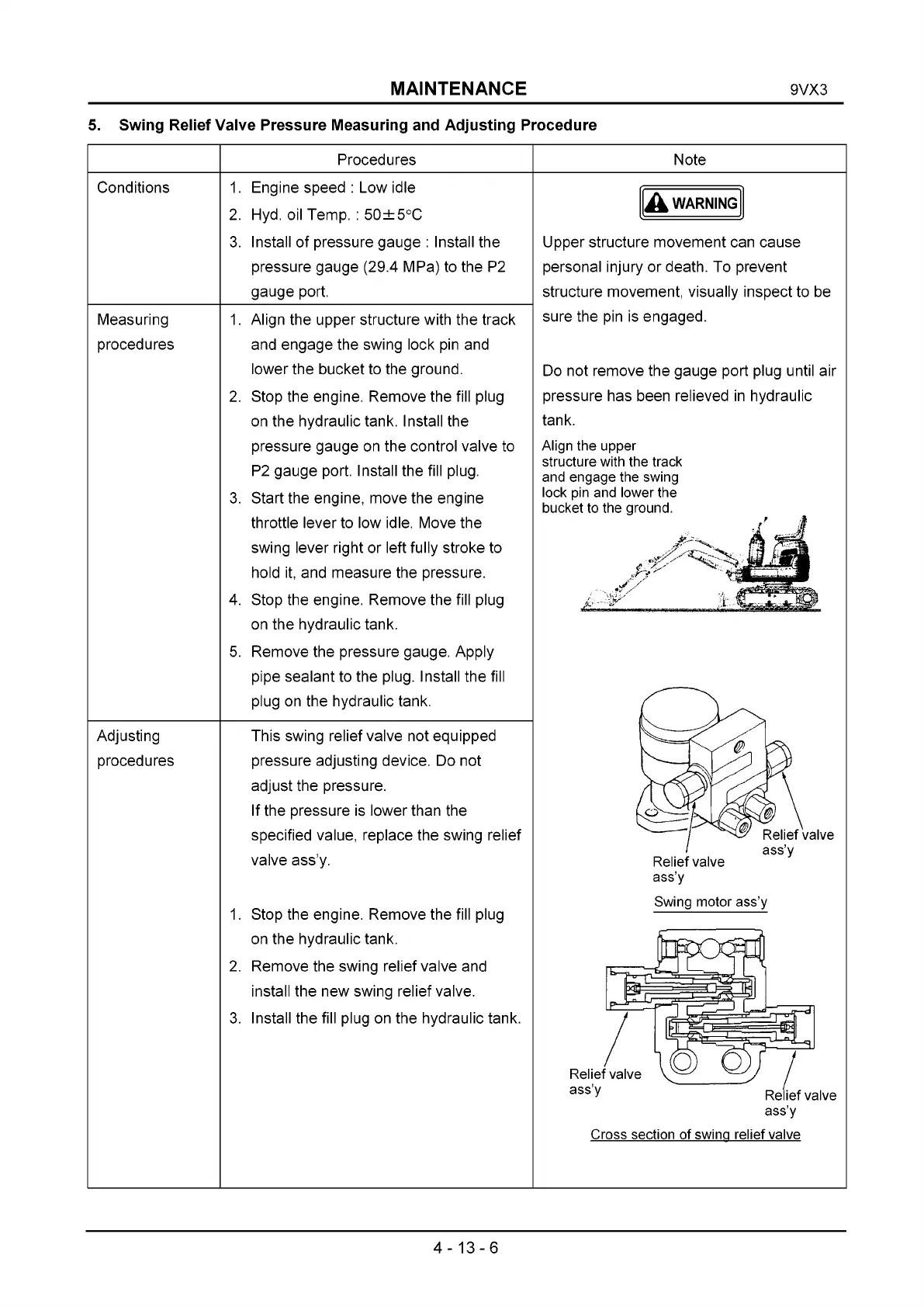

This swing relief valve not equipped

pressure adjusting device. Do not

adjust the pressure.

If the pressure is lower than the

specified value, replace the swing relief

valve ass’y.

1. Stop the engine. Remove the fill plug

on the hydraulic tank.

2. Remove the swing relief valve and

install the new swing relief valve.

3. Install the fill plug on the hydraulic tank.

A WARNING

Upper structure movement can cause

personal injury or death. To prevent

structure movement, visually inspect to be

sure the pin is engaged.

Do not remove the gauge port plug until air

pressure has been relieved in hydraulic

tank.

Align the upper

structure with the track

and engage the swing

lock pin and lower the

bucket to the ground.

Swing motor ass’y

Cross section of swing relief valve

4-13-6

Loading...

Loading...