OPERATION 9VX3

PRECAUTION ON USE OF RUBBER TRACK SHOE

FflCAUTSON'l

The rubber track shoe may be damaged or worn faster depending on working conditions.

Perform working operation properly according to working site conditions and machine operation.

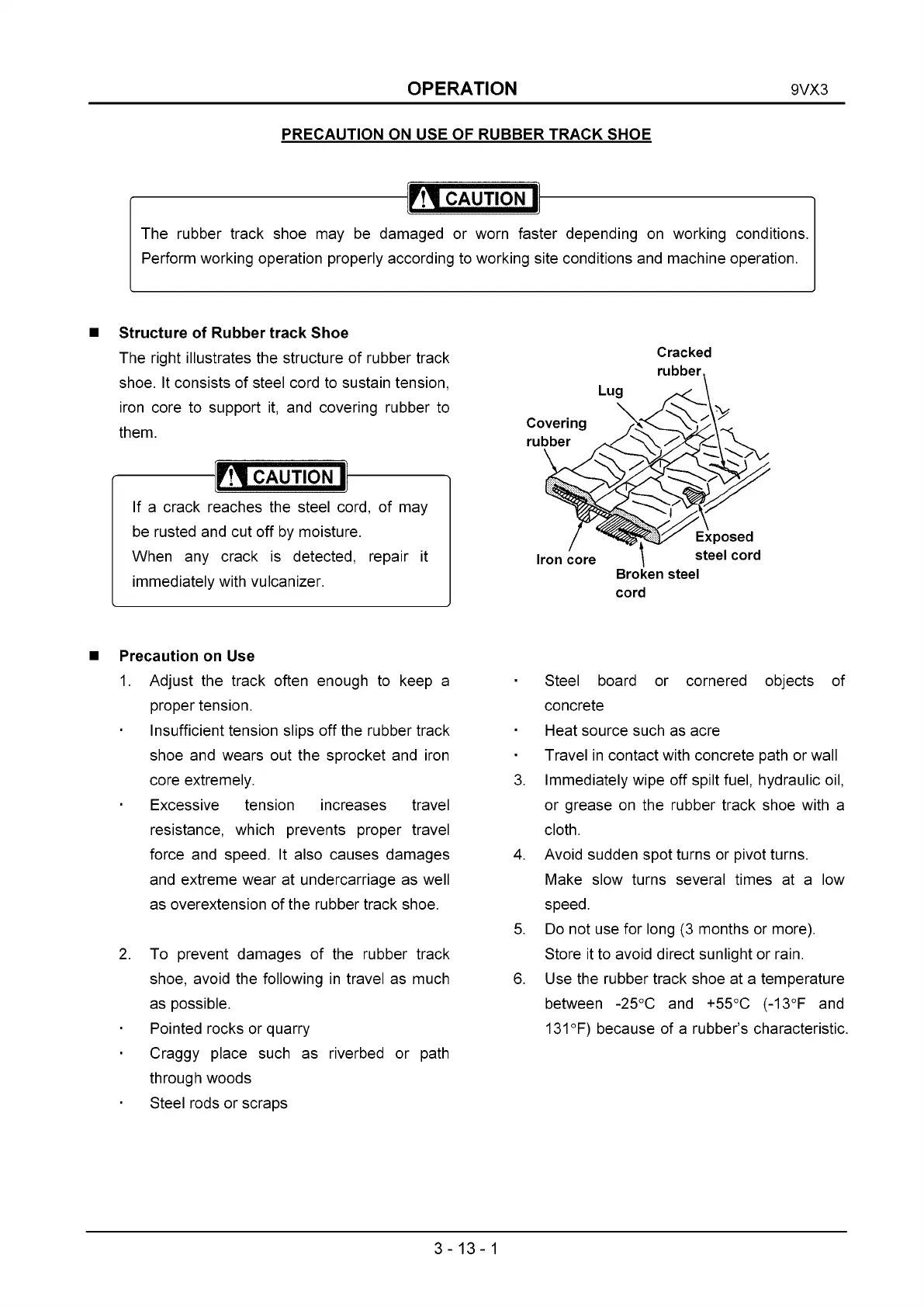

Structure of Rubber track Shoe

The right illustrates the structure of rubber track

shoe. It consists of steel cord to sustain tension,

iron core to support it, and covering rubber to

them.

CAUTION I

If a crack reaches the steel cord, of may

be rusted and cut off by moisture.

When any crack is detected, repair it

immediately with vulcanizer.

Cracked

cord

■ Precaution on Use

1. Adjust the track often enough to keep a

proper tension.

Insufficient tension slips off the rubber track

shoe and wears out the sprocket and iron

core extremely.

Excessive tension increases travel

resistance, which prevents proper travel

force and speed. It also causes damages

and extreme wear at undercarriage as well

as overextension of the rubber track shoe.

2. To prevent damages of the rubber track

shoe, avoid the following in travel as much

as possible.

Pointed rocks or quarry

Craggy place such as riverbed or path

through woods

Steel rods or scraps

Steel board or cornered objects of

concrete

Heat source such as acre

Travel in contact with concrete path or wall

3. Immediately wipe off spilt fuel, hydraulic oil,

or grease on the rubber track shoe with a

cloth.

4. Avoid sudden spot turns or pivot turns.

Make slow turns several times at a low

speed.

5. Do not use for long (3 months or more).

Store it to avoid direct sunlight or rain.

6. Use the rubber track shoe at a temperature

between -25°C and +55°C (-13°F and

131°F) because of a rubber’s characteristic.

3-13-1

Loading...

Loading...