iM3 Self Service Manual - Dental Units

www.im3vet.com

This manual outlines a step by step procedure to perform both a daily, weekly and annual service on

your iM3 GS Start, GS Deluxe, GS Deluxe LED, Elite or Pro2000 dental unit. Please note that servicing is

essential to maintain the dental unit’s optimal performance and to comply with warranty. If you have any

diculties or questions, you can contact a member of our team on +353 1 6911 277.

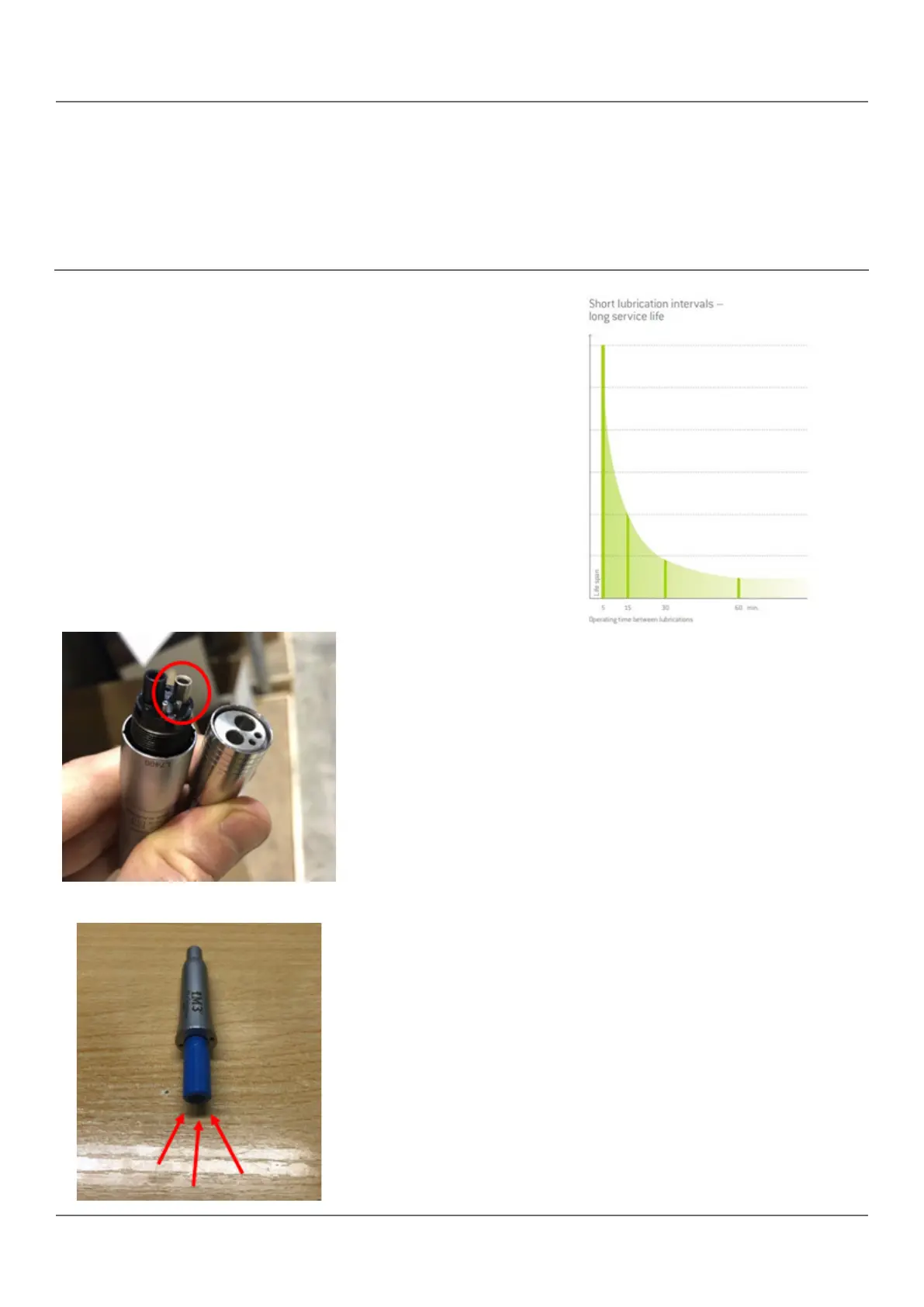

Oiling all of your handpieces is vital to keep them working

properly. This should ideally be done every 5 minutes of use

(drilling time, not surgery time). The below graph shows how

oiling at 5 minute intervals can signicantly increase the life span

of your handpiece.

Daily Maintenance

High Speed/Motors

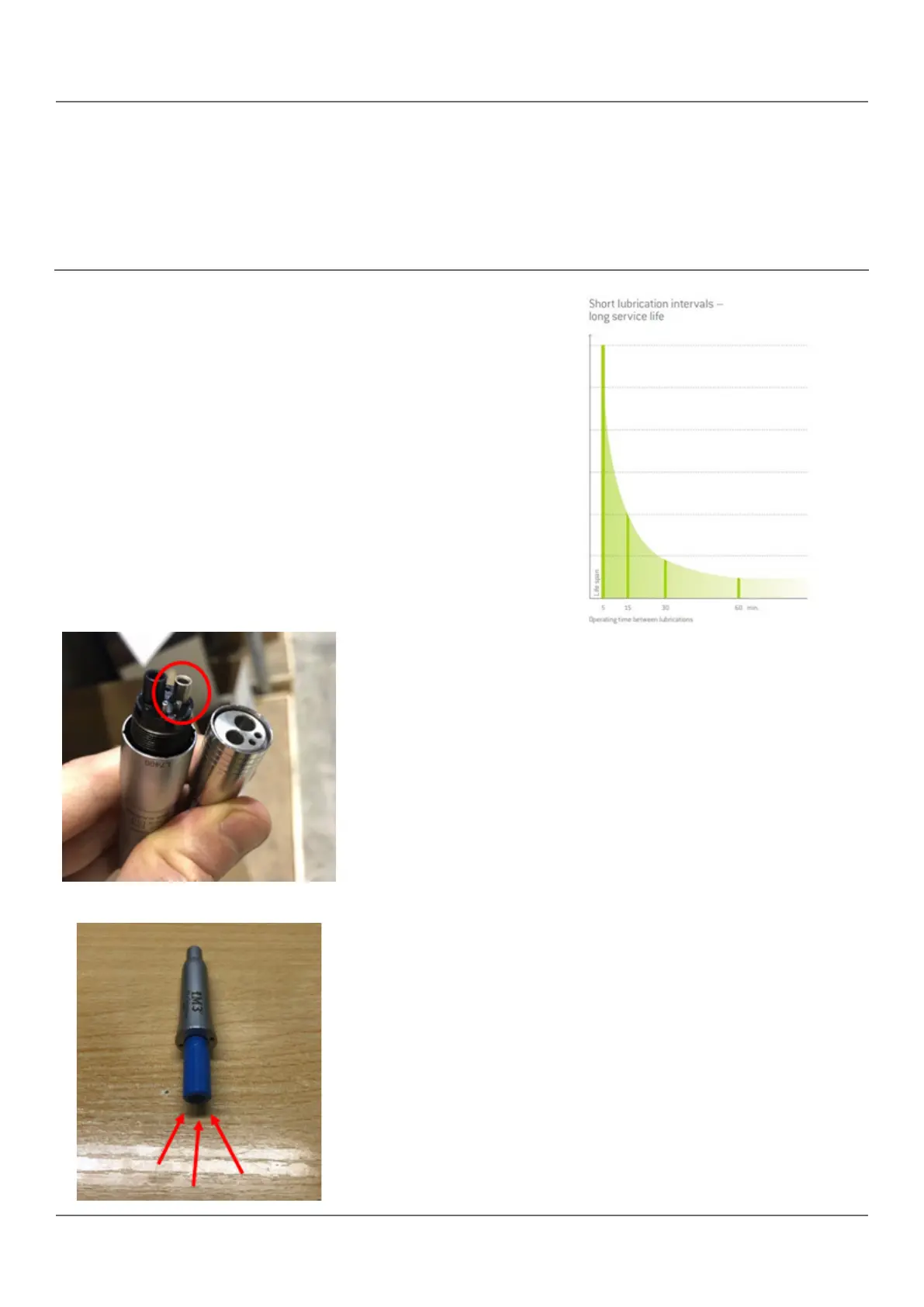

The turbine, located in the head of your high-speed handpiece,

rotates at 400,000rpm. Most cars have a maximum 7,000rpm which

puts this speed into perspective. To maintain these high speeds,

the turbine requires plenty of oil to stay lubricated. This is done by

unscrewing your handpiece from its connector and placing 4 drops

of iM3 oil (MD30) into the second largest hole. Re-connect your

handpiece and run it for 30 seconds while holding the handpiece

downwards so gravity pushes the oil to the turbine.

iM3 aerosol oil (MD40) can also be used by spraying directly into the

second largest hole, using the pointed nozzle, for 2 seconds. This will

eliminate the need to run the handpiece as the aerosol force will spin

the turbine and evenly distribute the oil.

Low Speed/Nose Cone/Contra Angle

To oil your cone attachments and contra angles, use iM3 aerosol with

the tubular nozzle. Seperate the cone/contra angle from the motor

and insert the nozzle. Spray for 2 seconds.

It is possible to oil using the drops method with the provided oiling

tube. Apply and operate for 30 seconds as for high speed handpieces.

Loading...

Loading...