INSTALLATION PROCEDURES

3-19

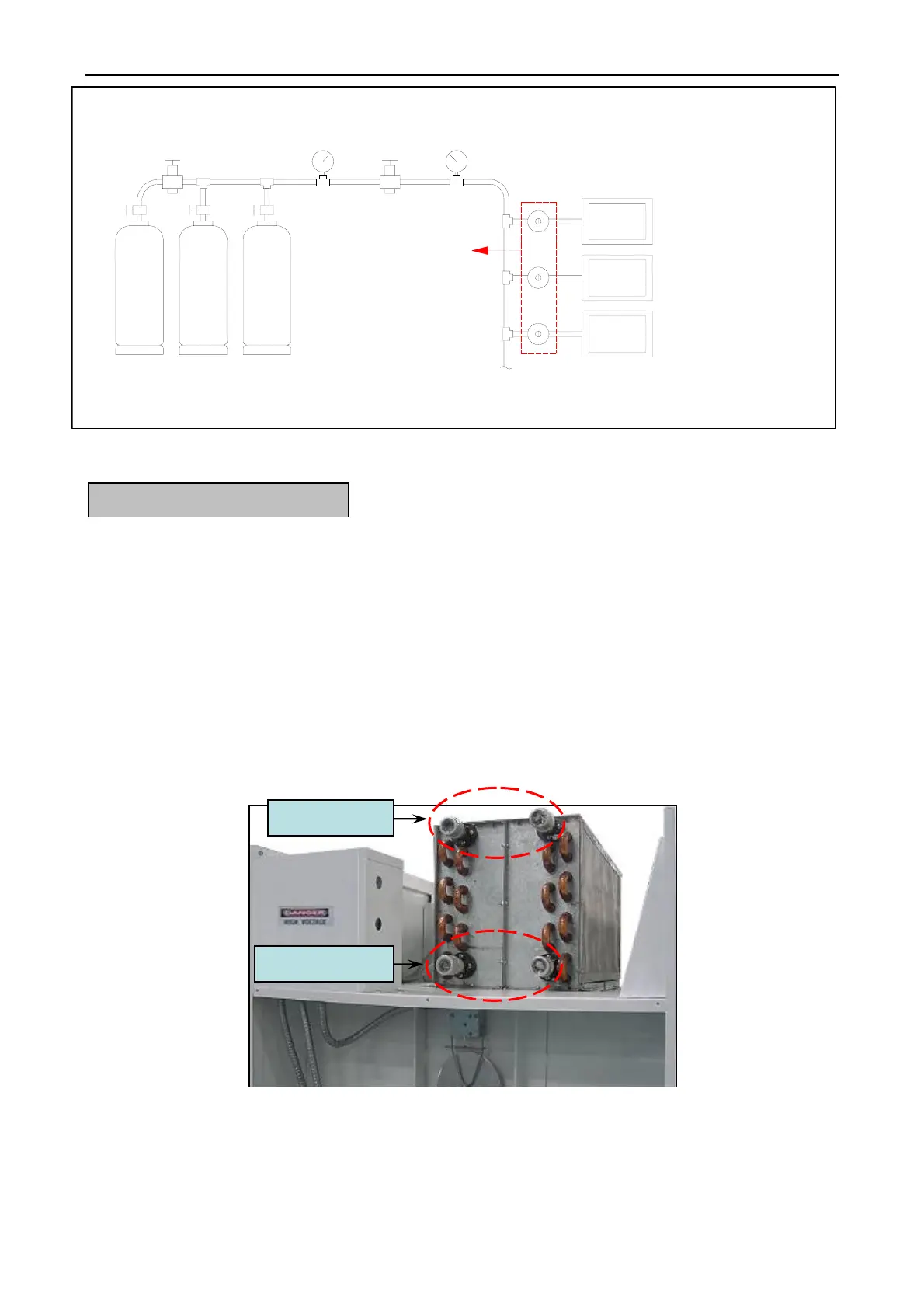

Figure.3-16 Typical of Gas Installation

Piping must be installed in accordance with good commercial steam system practice. Care

must be exercised when leveling steam dryers in final position. After leveling the dryer, check the

downward pitch of the heat exchanger from front to rear with a level. Likewise, check the

downward pitch of the return condensate manifold toward its outlet part. Absence of these

downward pitches will result in probable water hammer and premature heat exchanger fracture and

leakage.

The presence of condensate in the steam will cause water hammer and subsequent heat

exchanger failure. The steam supply connection must be taken from the top of a well-dripped steam

main. If the supply run – out to the dryer exceeds 20 feet, it should be dripped just before the

control valve with a proper trap and dirt pocket.

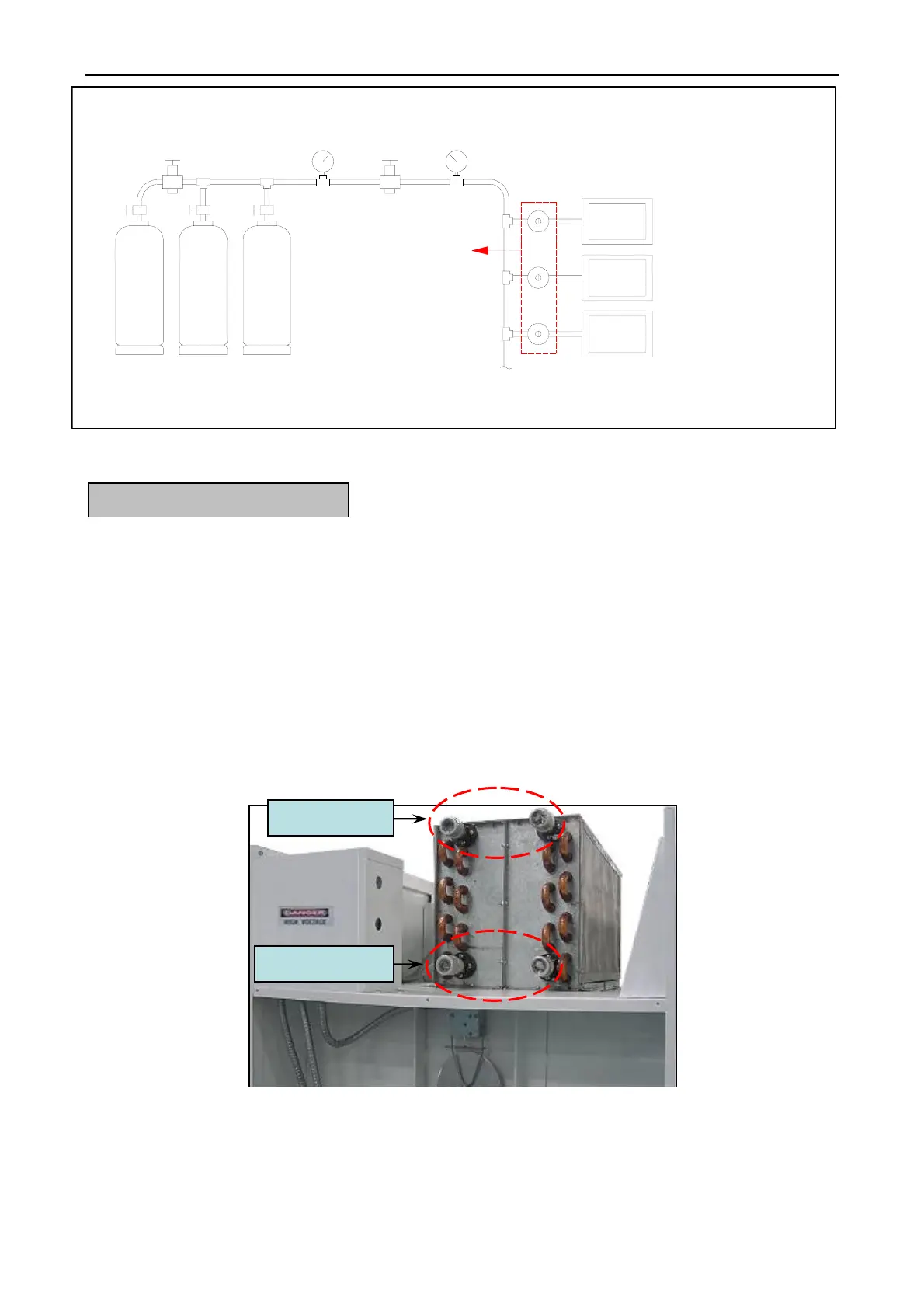

Figure.3-17 Typical of Steam Installation

H. STEAM INFORMATION

MAIN GAS SUPPLY TANKS

HIGH PRESSURE 0-300PSI

PRESSURE

RELIEF VALVE

HIGH PRESSURE

GAUGE 0-300PSI

PRESSURE GAUGE 0-60PSI

MEASURING 7PSI (0.48BAR)

HIGH PRESSURE

REGULATOR

GAS SUPPLY LINE 7PSI

LOW PRESSURE

SECOND STAGE

GAS REGULATOR

MAX INLET PRESSURE

10PSI (0.69BAR)

OUTLET PRESSURE

12-14 INCHES WC. (LPG)

4.5-14 INCHES WC. (NG)

GAS DRYER MACHINE

WITH GAS VALVE MAX INLET

PRESSURE 0.5PSI BUT IF USE

SECOND STAGE REGULATOR

WITH 11 INCHER WC. 0.41PSI (LPG)

4 INCHES WC.0.145 PSI (NG)

Steam Inlet

Steam Return

Loading...

Loading...