IMER U.S.A. Inc.

COMBI 250 VA

2

Dear Customer,

Congratulations on your choice of purchase: IMER saws are the result

of years of experience and are equipped with all the latest technical

innovations.

- WORKING IN SAFETY

To work in complete safety, read the following instructions care-

fully.

To work in complete safety, read the following instructions carefully be-

fore using the machine.

To work in complete safety, read the following instructions carefully be-

fore using the machine.

This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always be

available for consultation.

The manual is to be considered integral part of the machine and must

be kept for future reference (EN 12100-2) until the machine is disposed

of. If the manual is damaged or lost, a replacement may be requested

from the manufacturer.

The manual contains important information regarding site preparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experience and knowledge of the machine prior to use.

To guarantee complete safety of the operator, safe operation and long

life of equipment, follow the instructions in this manual carefully, and

observe all safety standards currently in force for the prevention of ac-

cidents at work (use of safety footwear and suitable clothing, helmets,

gloves, goggles etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of modifi cation to

the steel structure or working parts of the machine.

IMER INTERNATIONAL declines all responsibility for failure to com-

ply with laws and standards governing the use of this equipment, in

particular; improper use, defective power supply, lack of maintenance,

unauthorised modifi cations, and partial or total failure to observe the

instructions contained in this manual.

IMER INTERNATIONAL reserves the right to modify features of the saw

and contents of this manual, without the obligation to update previous

machines and/or manuals.

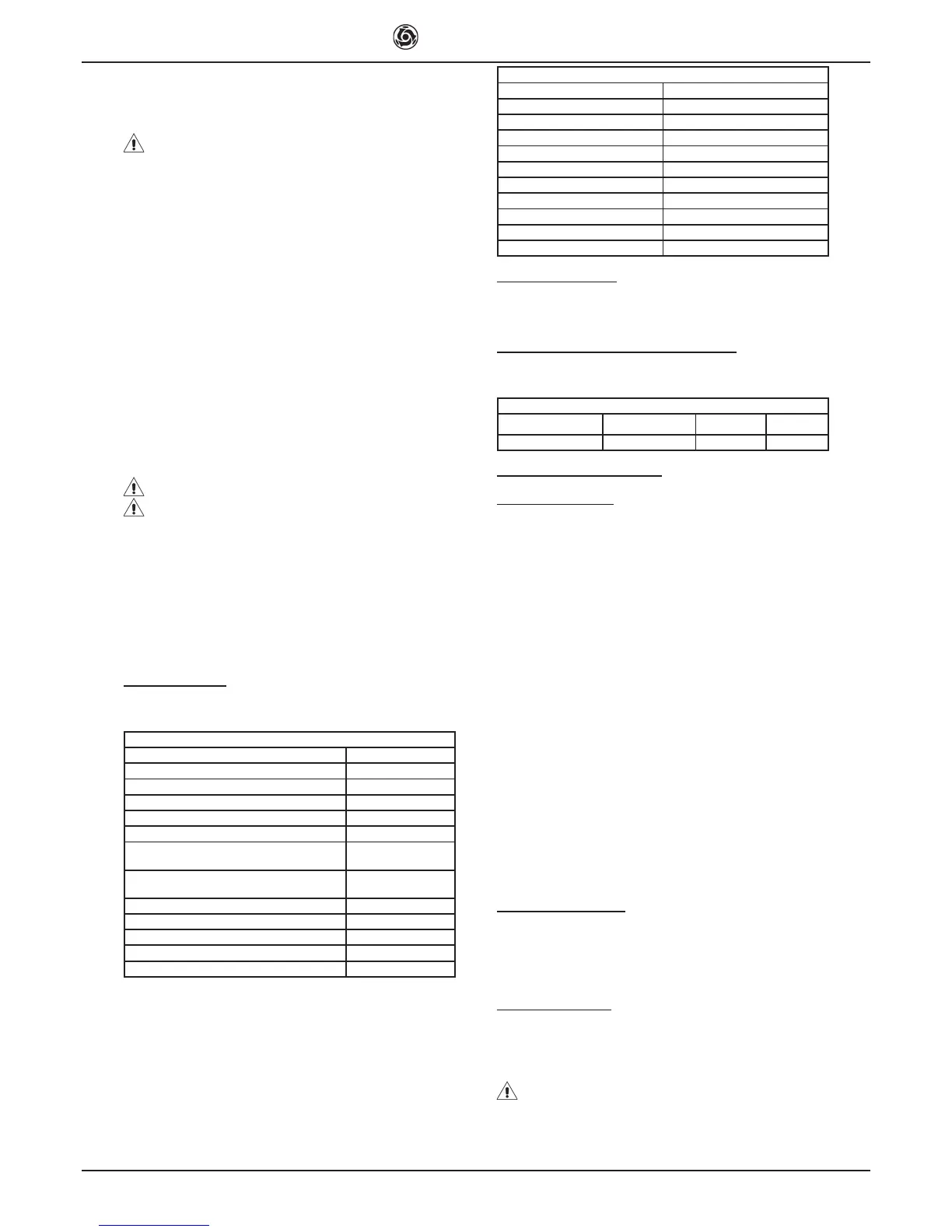

1. TECHNICAL DATA

Technical data are stated in table 1 and electrical specifi cations in table

2.

Table 1 - TECHNICAL DATA

Model Combi 250 VA

Max. blade diameter 10 inches

Diamond Blade hole diameter 5/8 inches

Single phase 115V/60Hz motor power 1.3 kW

Max. blade rotation speed 3.400 rpm

Cutting table dimensions 850x500 mm

Length of 90° cuts (thickness= 10mm)

Length of cuts from above

550 mm

600 mm

Maximum cut depth with single stroke

Maximum cut depth with two stroke

66 mm

105 mm

Water pump fl ow rate 13 L/1’

Water tank capacity 36 L

Machine dimensions 1050x565x480 mm

Packed machine dimensions 1090x610x525 mm

Weight with packaging 45.5 Kg

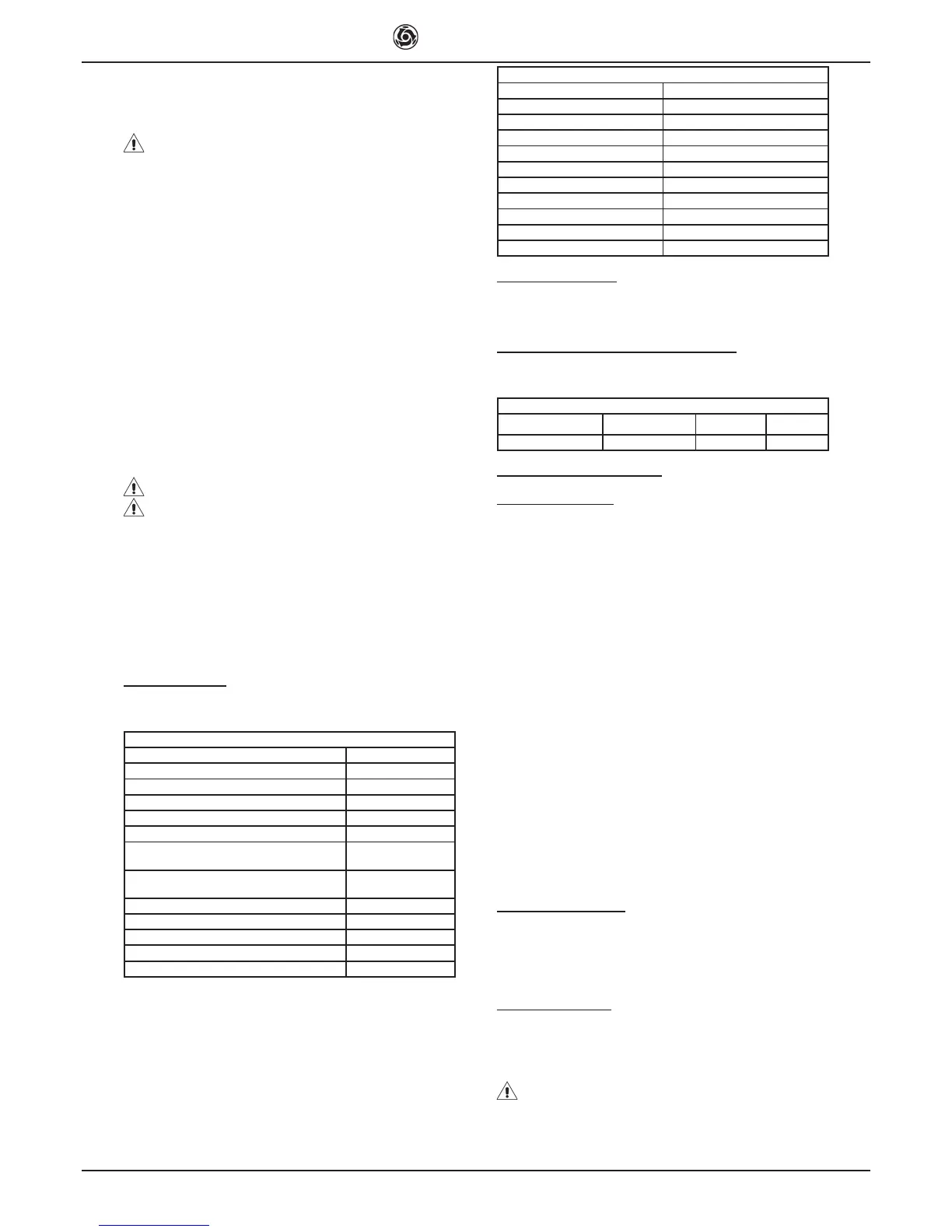

Table 2

Feature Motor (115V/60Hz)

Power (kW) 1.3

Rated voltage (V) 115

Frequency (Hz) 60

Absorbed current (A) 14.4

Number of poles 2

rpm 3400

Service type S6 40%

Insulation category F

Protection category IP55

Capacitor (μF) 110 (Ø 50x120)

2. DESIGN STANDARDS

Combi 250 VA saws have been designed and manufactured according

to the following standards: UNI EN 12418:2001; EN 12100-1/2:2005;

EN 60204-1:2006.

3. SOUND PRESSURE LEVEL AND VIBRATIONS

Table 3 shows the sound pressure level measured loadless at the ope-

rator’s ear (L

pA

) and of the vibrations transmitted during operation.

Table 3

Model Type of motor L

pA

A

eq

Combi 250 VA Electric 86 dB 2.57 m/s

2

4. GENERAL SAW DESCRIPTION

4.1 General description

The Combi 250 VA is a saw comprising the following main sub-groups:

• cutter head (ref.A, fi g.1)

• runner guide and arms (ref.B, fi g.1)

• cutting tables and heads (ref.C, fi g.1)

• water collection tank (ref.D, fi g.1)

• frame (ref.E, fi g.1)

The cutting head is mounted on a reinforced aluminium profi le and is

equipped with horizontal and vertical movement facilities. The alumi-

nium profi le is hinged onto die-cast arms (ref.F, fi g.1) and the entire

unit can rotate through 45° (fi g.2) by means of the relative handwheels

(ref.G, fi g.2).

The machine is supported by a special metallic frame. There is a

shockproof plastic tank between the machine and the frame. The water

immersion pump is mounted below the cutting surfaces on a special bra-

cket and supplies a water distributor inside the blade guard for cooling

the cutting blade during operation.

The high resistance plastic handle (ref.H, fi g.2), is equipped with the

main ON-OFF switch on the operator side to facilitate saw activation

and shutdown.The raised position of the red OFF button on the handle is

designed to facilitate shutdown of the machine in the event of an emer-

gency. The motor capacitor is located in a protected position inside the

handle.

The saw is fi tted with a guard to guarantee optimal safety during opera-

tion and to protect the user during cutting cycles.

A valve is mounted above the blade guard to adjust the fl ow rate of water

delivered to the cutting blade.

4.2 Processable materials

This saw has been designed for cutting the following materials: ceramic

tiles, masonry and stone in general with maximum dimensions com-

patible with the length, cutting depth and dimensions of the surfaces

specifi ed in table 1.

Maximum weight of processable materials: 25 kg.

4.3 Unsuitable material

Materials unsuitable for this machine are all those not specifi ed in pa-

ragraph 4.2.

In any event, before using the saw with materials other than as specifi ed

by the manufacturer for this saw model, contact IMER INTERNATIONAL

S.p.A.

- Use of this machine with workpieces outside the specifi ed

dimensions is strictly prohibited and constitutes a hazard for the

operator.

Loading...

Loading...