1

2

3

3

3

4

5

6

7

6

8

9

A

10

11

12

12

A

B

A

C

25

24

17

INSTALLERUSERMAINTENANCE TECHNICIAN

Kit composition:

1 1 Door adaptor Ø 100 or Ø 125

2 1 Door gasket made of neoprene

3 4 Screws 4.2 x 9 AF

4 1 Hex headed screw M6 x 20

5 1 Flat nylon washer M6

6 2 Door hole closure metal-sheet plate

plug

7 1 Plug gasket made of neoprene

8 1 Toothed washer M6

9 1 Nut M6

10 1 (kit 80/125) Concentric gasket Ø 60-100

11 1 (kit 80/125) Flanged adapter Ø 80-125)

12 4 (kit 80/125) Hex headed screws M4 x 16 slotted

- 1 (kit 80/125) Bag of lubricating talc

Supplied separately:

Installation drawings key:

Unique identication of the component in

the kit

Identication of the component not supplied

in this kit

1

A

Ref. Qty Description

A 1 Ducting kit door

Rigid Ø 80

ducting (A)

mm

SHAFT

(B) mm

SHAFT

(C) mm

86 126 146

Flexible Ø 80

ducting (A)

mm

SHAFT

(B) mm

SHAFT

(C) mm

90 130 150

1.17 ADAPTOR C9 KIT INSTALLATION.

is kit allows an indoor unit to be installed in

"C

93

" conguration, with combustion air intake

directly from the sha where the ue gas exhaust

is, obtained by means of a ducting system.

System composition.

e system must be combined with the following

components (sold separately) to be functional

and complete:

- kit C

93

Ø 100 or Ø125 version

- rigid ducting Ø 60 and Ø 80 and exible Ø 50

and Ø 80 kit;

- ue exhaust kit Ø 60/100 or Ø 80/125 cong-

ured according to the installation and type of

indoor unit.

Kit Assembly.

- Mount the components of kit "C9" on the door

(A) of the ducting system (Fig. 25).

- (Version Ø 125 only) mount the anged adap-

tor (11) interposing the concentric gasket (10)

on the heat generator, tting it with the screws

(12).

- Mount the ducting system as described in the

relative instructions sheet.

- Calculate the distances between the indoor unit

drain and the bend of the ducting system.

- Prepare the indoor unit ue system, making

sure that the internal pipe of the concentric kit

is tted up to the end stop in the ducting system

curve (Quota "X" Fig. 26), whereas the external

pipe must reach the end stop of the adapter (1).

N.B.: to encourage the removal of possible

condensate forming in the exhaust pipe, tilt the

pipes towards the indoor unit with a minimum

slope of 1.5%.

- Mount the cover (A) complete with adaptor (1)

and caps (6) on the wall and assemble the ue

system to the ducting system.

N.B.: (version Ø 125 only) before assembly check

the gaskets are in the right position. In the event

component lubrication (already carried out

by the manufacturer) is not sucient, remove

the residual lubricant using a dry cloth, then

to ease tting coat the parts with common or

industrial talc.

Once all components have been assembled prop-

erly, the exhaust fumes will be expelled via the

ducting system; the combustion air for normal

heat generator operation will be aspirated directly

by the sha (Fig. 26).

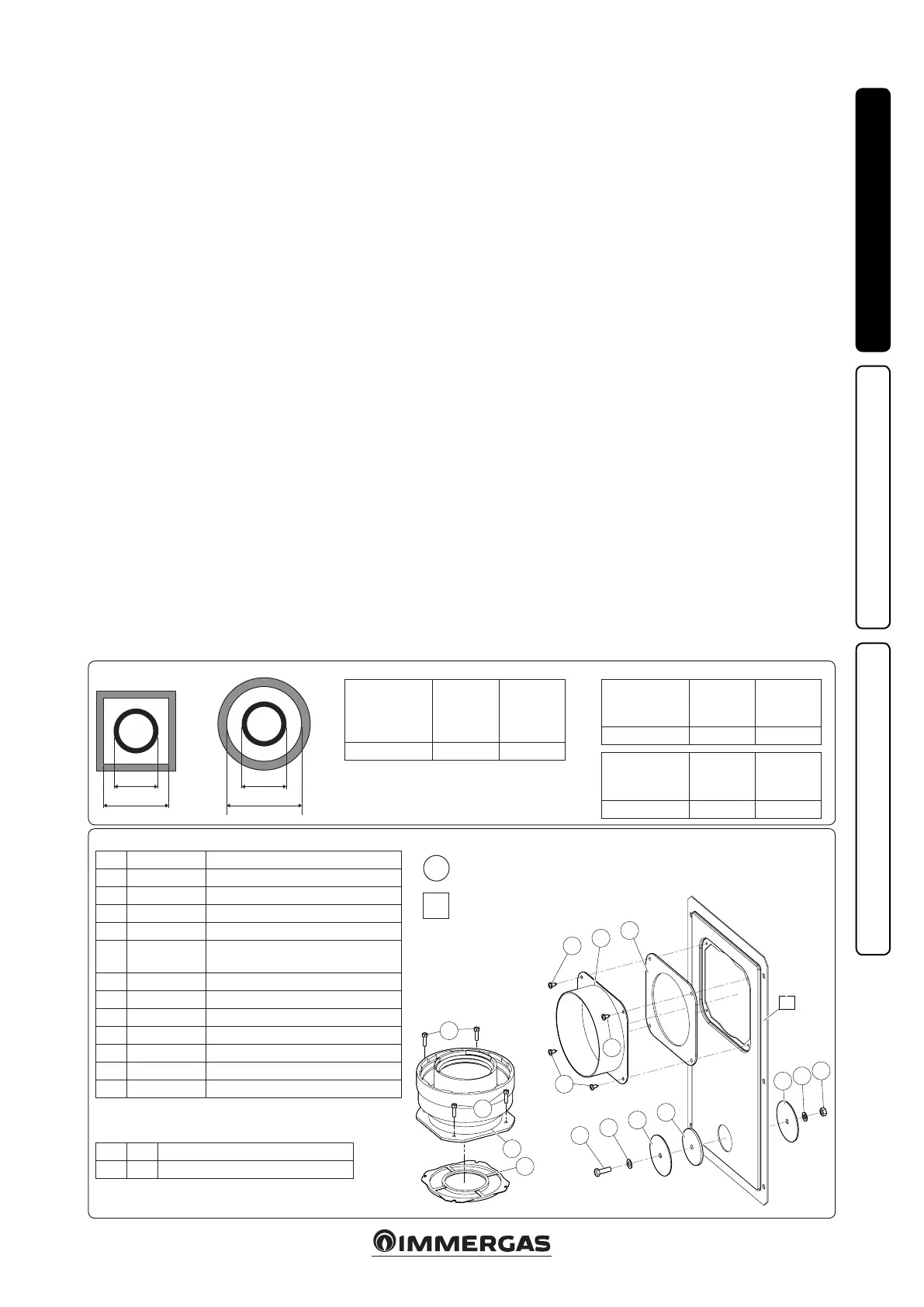

Technical data.

- e dimensions of the shas must ensure a

minimum gap between the outer wall of the

smoke duct and the inner wall of the sha: 30

mm for circular section shas and 20 mm in

the event of a square section sha (Fig. 24).

- Maximum 2 changes of direction are allowed

on the vertical section of the ue system with

a maximum clearance angle of 30° with respect

to the vertical.

- e maximum vertical extension using a Ø

60 ducting system is 13 m, the maximum

extension includes 1 bend Ø 60/10 at 90°, 1 m

of horizontal pipe 60/100, 1 90° ducted bend

Ø 60 and the roof terminal for ducting.

To determine the C

93

ue system in cong-

urations other than that described (Fig. 26)

one must consider that 1 metre of ducted pipe

according to the indications described has a

resistance factor equal to 4.9.

- e maximum vertical extension using a Ø 80

ducting system is 28 m, the maximum exten-

sion includes 1 adapter 60/100 to 80/125, 1 87°

bend Ø 80/125, 1 m of horizontal pipe 80/125,

1 90° ducted bend Ø 80 and the roof terminal

for ducting.

To determine the C

93

ue system in congu-

rations other than that described (Fig. 26) one

must consider the following pressure drops:

- 1 m of concentric pipe Ø 80/125 = 1 m of

ducted pipe;

- 1 87° bend = 1.4 m of ducted pipe;

Consequently one must subtract the equivalent

length of the part added to the 28 m available.

Flexible Ø 50

and Rigid Ø

60 ducting (A)

mm

SHAFT

(B) mm

SHAFT

(C) mm

66 106 126

Loading...

Loading...