Do you have a question about the Ingersoll-Rand Precedent W/DHC036H and is the answer not in the manual?

| Brand | Ingersoll-Rand |

|---|---|

| Model | Precedent W/DHC036H |

| Category | Heat Pump |

| Language | English |

Defines advisory types (Warning, Caution, Notice) for safety and operational guidance.

Discusses the impact of chemicals on the ozone layer and responsible refrigerant handling.

Outlines best practices for refrigerant handling and technician certification requirements.

Explains the meaning of each digit in the unit model number for identification.

Provides important clarifications and exceptions related to specific model number digits and configurations.

Details procedures for inspecting units upon arrival and proper storage to prevent damage.

Describes unit features, components like ReliaTel™ Control, and optional interfaces (RTCI, RLCI).

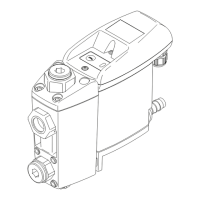

Explains various sensors and switches that provide input to the control system for unit operation.

Details safety measures and PPE required when working with fiberglass insulation during installation.

Provides diagrams and data for unit placement, clearances, and rigging procedures.

Lists detailed weight specifications for various unit models and corner weight distributions.

Outlines foundation needs, roof curb installation, and ductwork connection guidelines.

Details procedures for rigging units, including safety warnings and alignment.

Provides a checklist for essential steps required for successful commercial unit installation.

Details steps for converting units to horizontal discharge for specific models.

Covers main power requirements, grounding, and through-the-base gas installation procedures.

Explains how to configure condensate drains for front, base, or through-the-base drainage.

Details requirements for field-installed power wiring, including grounding and conductor sizing.

Covers procedures for field-installed control wiring, including low voltage and wiring practices.

Explains wiring considerations for 24 Vac controls, including conductor resistance and routing.

Details wiring guidelines for DC analog inputs/outputs and zone sensor module wiring.

Explains how to set up space temperature averaging using multiple remote sensors.

Illustrates typical field wiring diagrams for various optional controls and system components.

Explains how to measure and calculate voltage imbalance in three-phase power for motor protection.

Details procedures for checking and ensuring correct electrical phasing for proper motor rotation.

Discusses the importance and operation of crankcase heaters for compressor oil temperature.

Describes ReliaTel™ control self-diagnostics, test modes, and sequence initiation.

Outlines three methods (Step, Resistance, Auto) for testing unit components during pre-start.

Introduces control options (electromechanical, ReliaTel™) and basic unit operation sequences.

Details ReliaTel™ control features for CV units, including anti-short cycle and diagnostics.

Explains cooling sequences for units with and without economizers, including staging and low ambient.

Describes ReliaTel™ control of the evaporator fan for cooling-only and gas units.

Covers control of multi-speed indoor motors and associated supply fan output percentages.

Explains how ReliaTel™ controls supply fan speed to maintain duct static pressure.

Explains controls for cooling/economizer, setpoint reset, and zone temperature management.

Covers supply fan control, minimum output, and discharge air cool setpoint adjustments for VAV units.

Describes how the economizer is utilized to control zone temperature and optimize cooling.

Details dehumidification cycles, including single/dual compressor operation and purge cycles.

Explains how to adjust the economizer's minimum position for ventilation air control.

Explains heating control sequences for cooling-only and gas units, including ignition module.

Explains heating cycles, defrost initiation, and control logic for maintaining zone temperature.

Covers emergency heat operation and procedures for verifying proper airflow for unit performance.

Details airflow control for direct drive and belt drive fans, including CFM adjustment.

Describes airflow control for constant CFM direct drive fans and adjustment procedures.

Explains airflow adjustment for units with direct drive plenum fans using service test modes.

Explains the function and installation requirements for the return air smoke detector.

Details how to set the economizer's minimum damper position for various fan speeds.

Guides through starting compressors, verifying rotation, and checking operating pressures.

Covers heating start-up checks and final procedures before leaving the unit for operation.

Provides instructions for adjusting and maintaining fan belt tension for optimal performance.

Details the process for replacing fan belts, including tension gauge usage and force values.

Outlines routine checks for filters, smoke detectors, condensate drains, and general unit inspection.

Details the process for cleaning evaporator and condenser coils safely and effectively.

Explains how to safely remove and reinstall hail guards for coil access and cleaning.

Provides a final checklist and a sample log for recording unit data during maintenance.

Explains how to check system status, LED indicators, and diagnose ReliaTel™ control issues.

Details methods for checking system status using zone sensor LEDs and voltage readings.

Lists common system failures, their causes, and corresponding voltage readings for diagnosis.

Provides methods for resetting cooling and heating lockouts from the space or at the unit.

Outlines procedures for testing ZTS components, including thermistor, setpoints, and mode selection.

Describes methods for testing unit LEDs (System, Heat, Cool, Service) using meters.

Details testing procedures for serial communication voltage and ZSM functionality.

Explains RTRM default modes and temporary operation without a zone sensor.

Covers troubleshooting the economizer actuator (ECA) status and error codes.

Explains the diagnostic for mixed air temperature falling below a set limit and its resolution.

Provides procedures for troubleshooting direct drive plenum fans, including motor protection.

Lists drawing numbers for various unit schematics, power, and connection diagrams.

Outlines warranty terms for heat pumps, including coverage, exclusions, and duration.

Specifies warranty applicability for commercial usage and commercial use definitions.

Loading...

Loading...