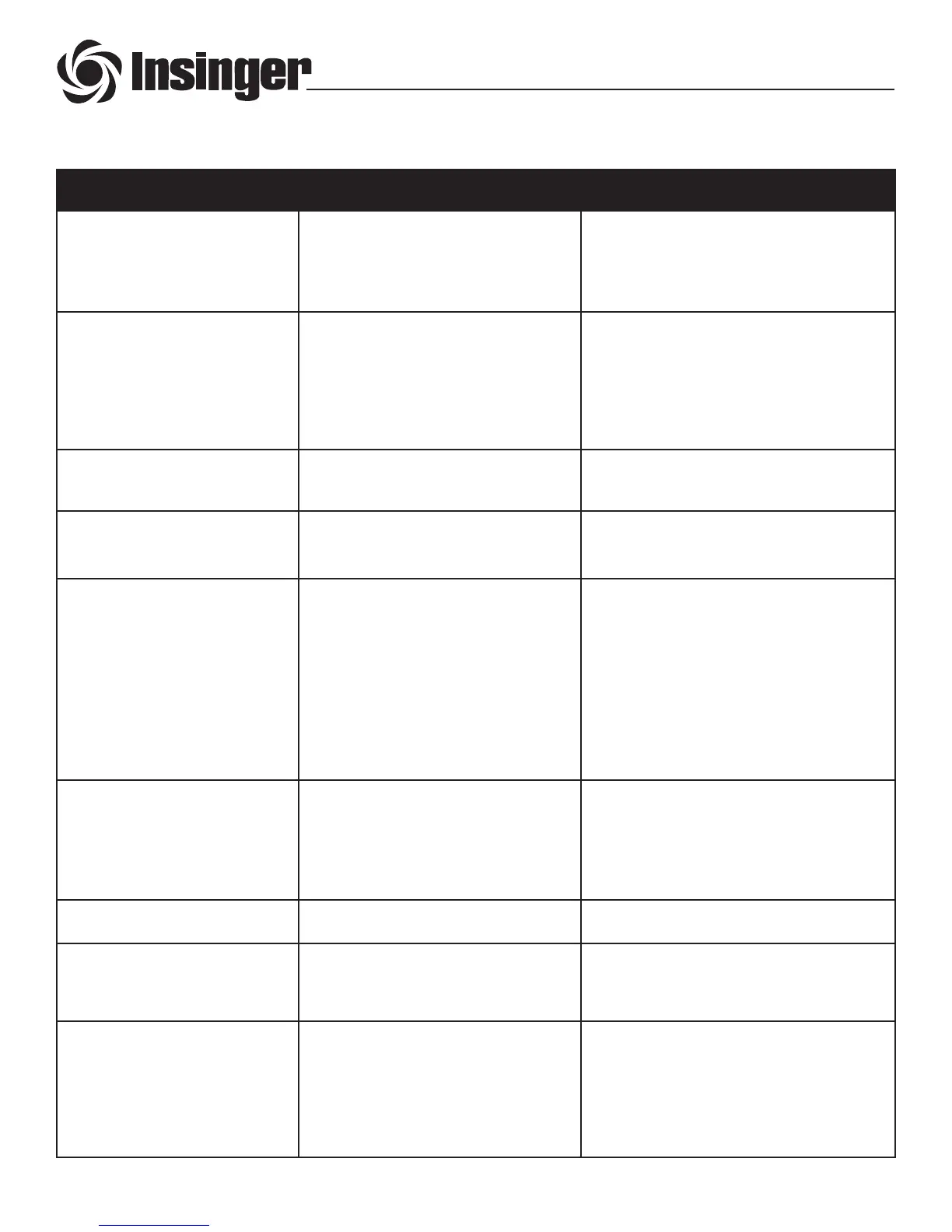

TECHNICAL ISSUES

POSSIBLE CAUSES SOLUTIONS

Machine will not operate 1. No power

2. Blown fuse or tripped breaker

3. Motor overloads tripped

1. Check power supply

2. Replace fuse; reset breaker

3. Reset overload

Tank will not hold water 1. Drain not closed

2. Drain overow not seated or

installed

3. Pump petcock opened

4. Overow v-seal dirty/worn

1. Close drain

2. Reseat or install drain overow

3. Close pump petcock

4. Clean/replace v-seal

Tank lls beyond overow 1. Obstruction in overow tube or

drain line

1. Remove obstruction

Water leaks around door 1. Doors not seating

2. Clogged spray pipe

1. Reseat doors

2. Clean spray pipe with brush

Weak or ineective spray 1. Clogged spray pipe

2. Manifolds not installed properly

3. Obstruction in pump

4. Pump rotation reversed

5. Suction strainer clogged

1. Clean spray pipe with brush pipe

2. Ensure proper placement of upper and

lower pipes

3. Clear obstruction through pump

inspection plate

4. Arrow on pump housing indicates

direction, correct electrically

5. Clean suction strainer

Weak or ineective nal rinse

spray

1. Lime deposits in spray nozzles

2. Low water pressure

3. Clogged line strainer

4. Closed water supply valve

1. Clean or replace nozzles

2. Adjust to 20PSI

3. Remove line strainer and clean

4. Open ball valve

Water hammer 1. Excessive water line pressure 1. Install water hammer valve

Machine vibrates or is noisy 1. Pump rotation reversed

2. Pump bearings worn

1. Arrow on pump housing indicates

direction, correct electrically

2. Replace pump bearings

Final rinse will not shut o 1. Final rinse solenoid valve clogged

2. Diaphragm worn

3. Solenoid valve still powered-up

1. Disassemble valve and clean internal

parts of scale or replace

2. Replace with solenoid valve repair kit

3. Check nal rinse actuating circuit for

proper operation

PART 5 MAINTENANCE & REPAIR PROCEDURES

19

®

TROUBLESHOOTING

CA-3 & DA-3 Technical Manual 2018 www.insingermachine.com 800-344-4802

Loading...

Loading...