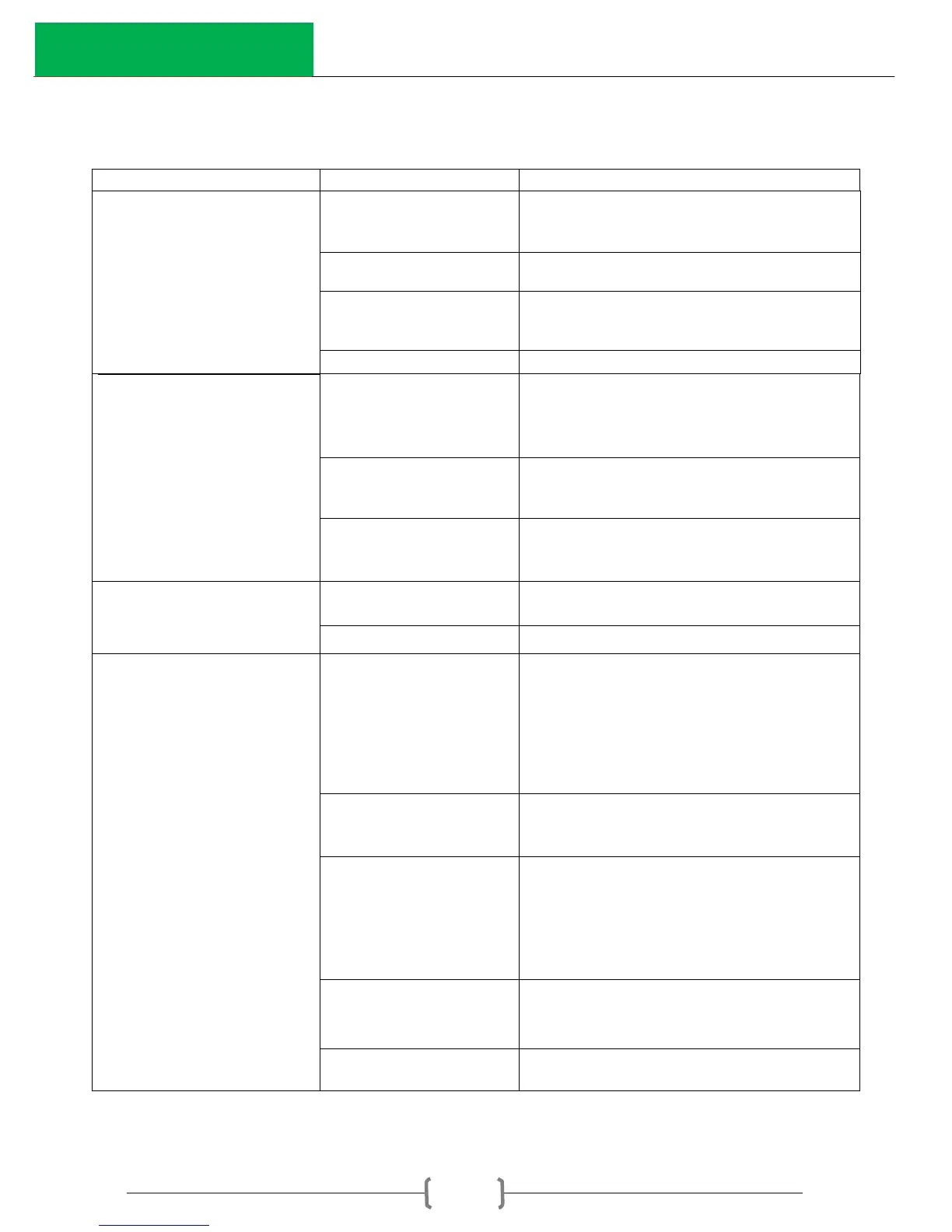

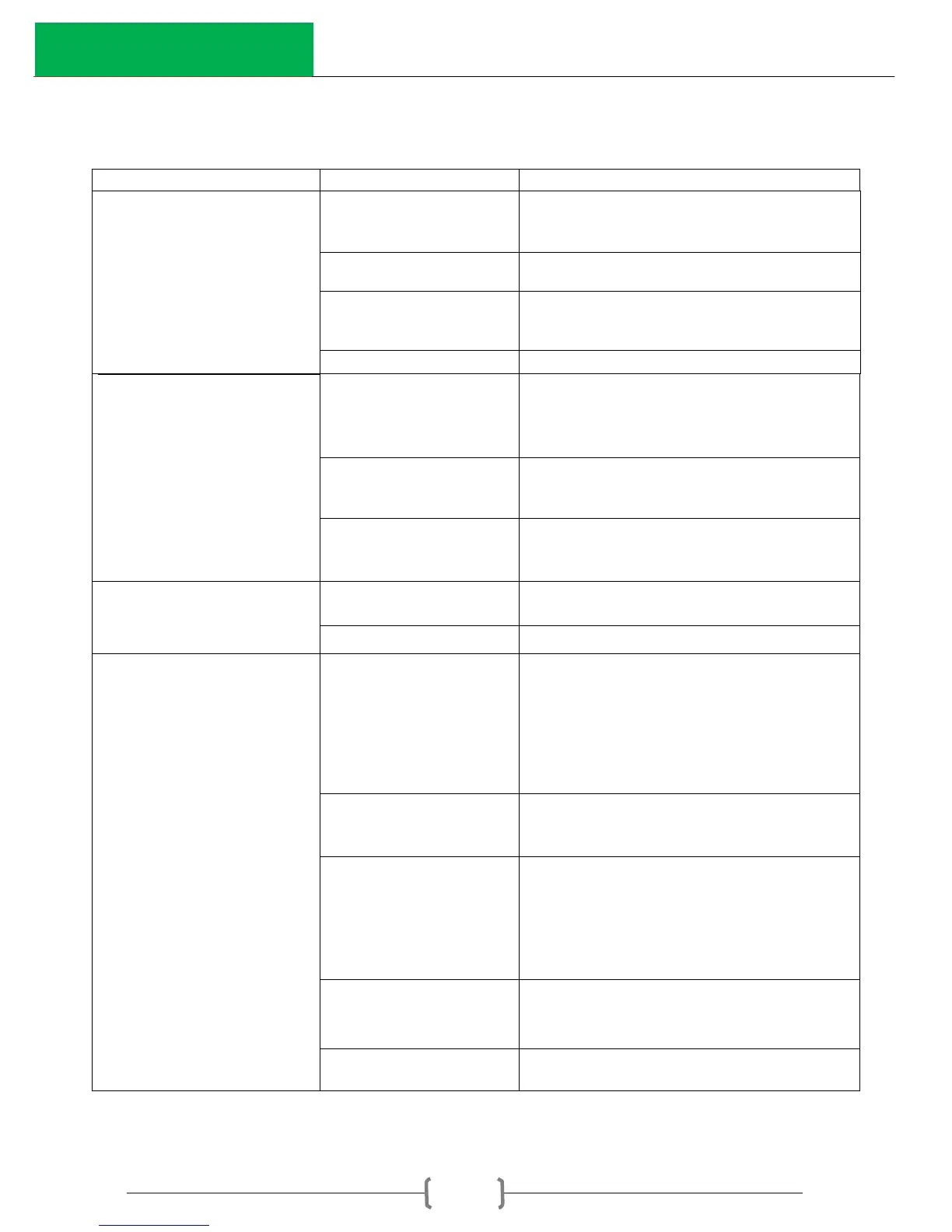

Troubleshooting

No Power

(Vacuum pump does not

run)

Power switch located on right of control

panel may be off. Switch to “ON” position

(display will light up).

The sample is too large. Remove one or

more filler plates.

Power cord loose or

damaged.

Check to ensure wall outlet is working.

Plug in a different appliance to verify.

Power cord attached securely?

Check fuse on front panel. (pg. 43)

No Vacuum

(pump runs but lid does not

stay closed)

Check black seal gasket in the lid. It

should be seated evenly in the groove

and there should not be any cuts, gaps or

debris.

Vacuum ports are

blocked or clogged.

The sample bag is blocking the two

vacuum ports in the rear of the chamber.

Your bag may need to be repositioned.

Cut or disconnected

hose.

Hose accidentally cut or disconnected

during recent servicing or oil change.

Contact InstroTek.

Damaged or broken

seal wire.

Call for replacement seal bar or wire and

tape.

Check fuse on front panel. (pg. 43)

Inadequate Seal

(seal appears too light,

spotty, or inconsistent from

end to end)

Wrinkles in the bag or

debris in the sealing

area.

If the sealing surface in the bag is smooth,

clean and free of debris. If the sample is

too big for the bag, you may not be able

to lay the open end of the bag evenly

across the seal bar.

Make sure tape over the seal wire is

smooth and wrinkle free.

Center the bag evenly over the seal bar.

Make sure the bag width is not larger than

the seal bar width.

Punctures on the

sample edges

Make sure the sliding plate is used with the

smooth side down. Make sure the top of

the sample is not hitting the chamber

door. Remove one or more of the filler

plates. Make sure the bags are not

damaged by inspecting prior to use

Damaged or worn

silicone seal pad in lid

(above seal bar).

The silicone pad is not firmly seated in its

holder or it is cut, damaged or not smooth.

Replace if necessary.

Tape on seal bar is not

even or smooth.

Worn or frayed. Replace if necessary.

Loading...

Loading...