Interklima Dx Cassette Units

II-IO CCV1 R410A / Rotary / Scroll

36

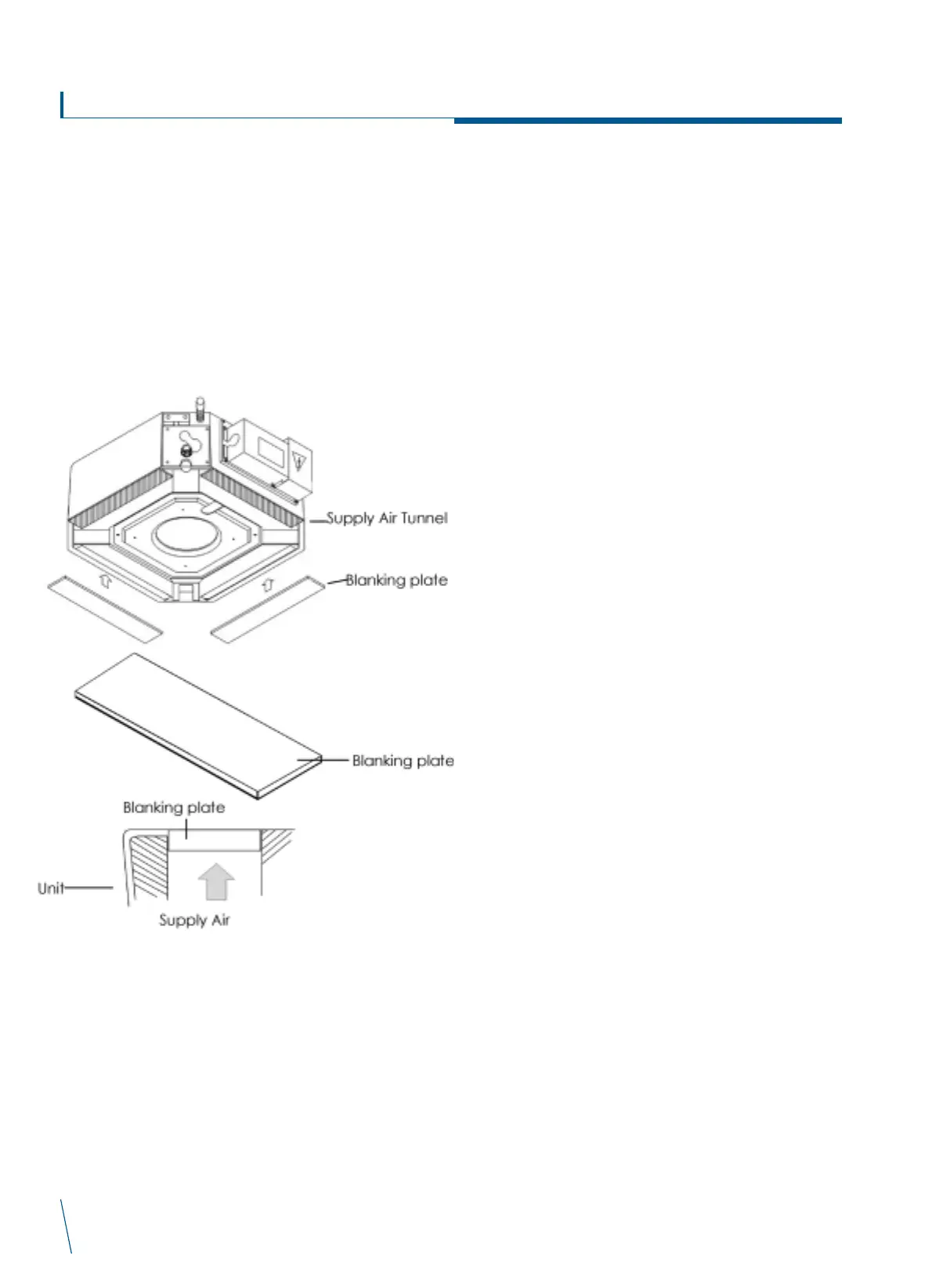

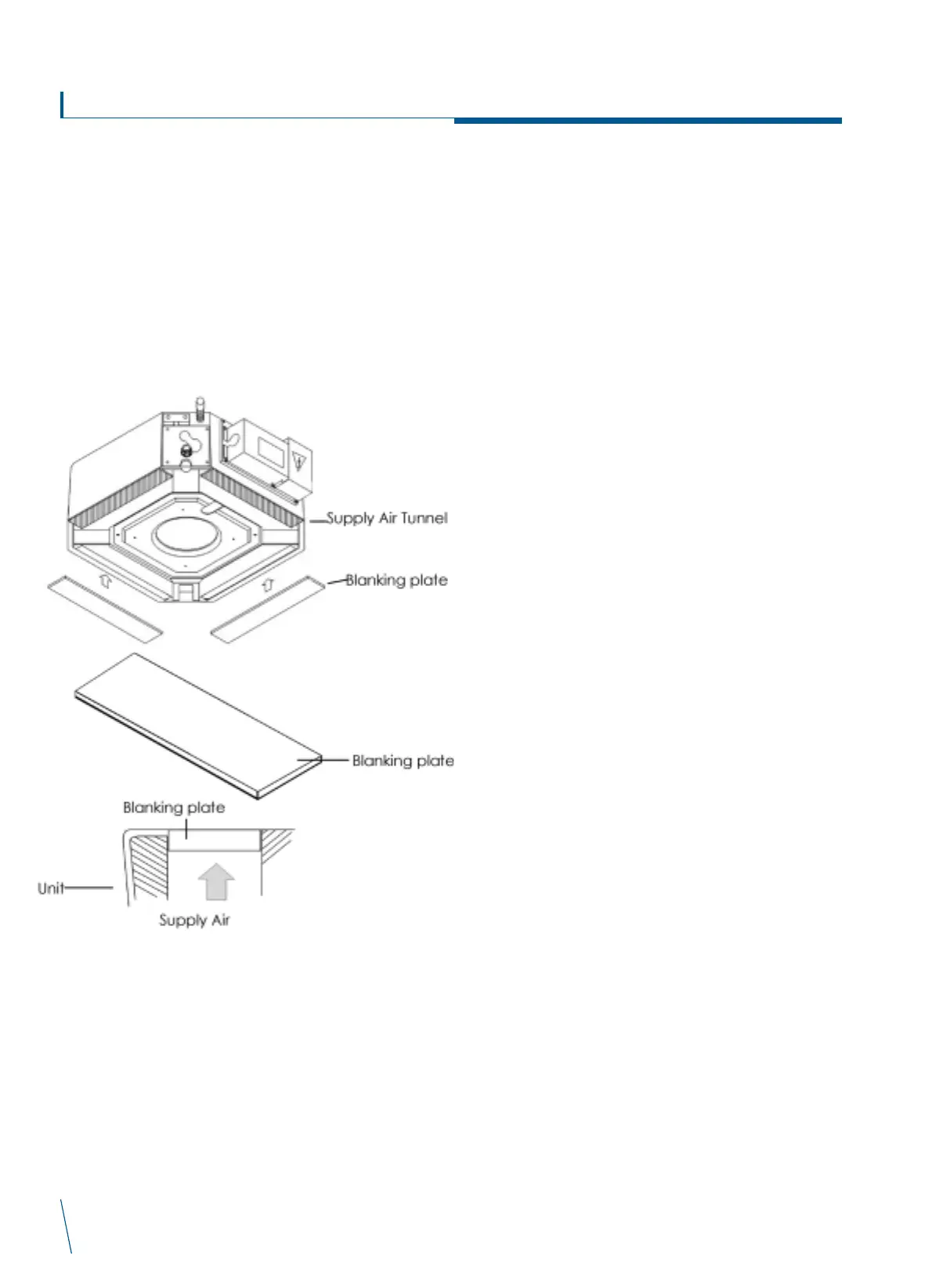

BLANKING PLATES

See the following diagram and installation method.

How to install

1) Peel off the cover paper to expose adhesive surface of the

blanking plate.

2) Apply blanking plate on the supply air tunnel to cover the

opening.

3) Press on the attaching area to firmly seal it.

INSTALLATION, START UP AND SERVICE INSTRUCTIONS FOR

CONDENSING UNITS

COMPRESSOR LUBRICANT: POE(polyol ester) or synoil are

typically used as the lubricant for R-410A.

CHARGING SYSTEM WITH R-410A: It is essential when charging

the system with R-410A that the system be liquid charged by

removing only liquid from the cylinder. Never charge the system

with vapour from a cylinder. Vapor charging R-410A may result in

the wrong refrigerant composition and could damage the system.

Therefore the cylinder must be equipped with a dip tube to

facilitate liquid removal with the cylinder in the upright position.

LEAK DETECTION: Service personnel have used leak detection

equipment for years when servicing equipment. Leak detectors exist

not only for pinpointing specific leaks, but also for monitoring an

entire room on a continual basis for the absence of oxygen or

presence of r frigerants. There are several reasons for leak

pinpointing or area monitoring, including: conservation of

refrigerants, protection of valuable equipment, reduction of fugitive

emissions, and protection of employees. Prior to the purchase of

detector or monitor, make sure you consider your requirements or

criteria for the monitor such as sensitivity, detection limits, and

selectivity. Another simple method used to find leaks is to coat the

suspect area with a soapy water solution and look for soap bubbles.

CHECK SYSTEM OPERATION: Start the system and let conditions

stabilize. If the system is under charged, add additional R-410A in

increments of 5 percent by weight. Continue until desired

conditions, 2700 kpa for high pressure and 700 kpa for low

pressure, are achieved.

REFRIGERANT CHARGING: If recharging is necessary, weight in

the total charge as indicated in the charging table. Remove any

refrigerant remaining in the system before recharging. If the system

has lost the complete charge, evacuate and recharge by weight.

STEP 1 - COMPLETE PRE-INSTALLATION CHECKS

UNPACK UNIT - Move unit to its final location. Remove the carton

from unit being careful not to damage the service valves and grilles.

INSPECT SHIPMENT - File a claim with the shipping company if

the shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS - Consult the local building

and national electrical codes for any special installation

requirements.

Allow sufficient space for air flow clearance, wiring, refrigerant

piping, and servicing the unit. See fig. 1.Locate the unit so that the

condenser's air flow is unrestricted on both sides. Refer to fig. 2.

The unit may be mounted on a level pad directly on its base legs

or mounted on raised pads at the support points.

STEP 2 - RIG AND MOUNT UNIT

MOUNTING ON GROUND - Mount on a solid, level, concrete pad.

Position unit so water or ice from the roof cannot drop directly

onto the unit. If local codes require the unit be fastened to the pad,

tie down bolts should be used and fastened through the slots

provided in the unit's mounting feet.

MOUNTING ON ROOF - Mount on a level platform or frame. See fig.2.

RIGGING

Be sure unit panels are securely in place prior to rigging.

Keep unit upright. Lift unit using slings. Use cardboard or padding

Loading...

Loading...