9

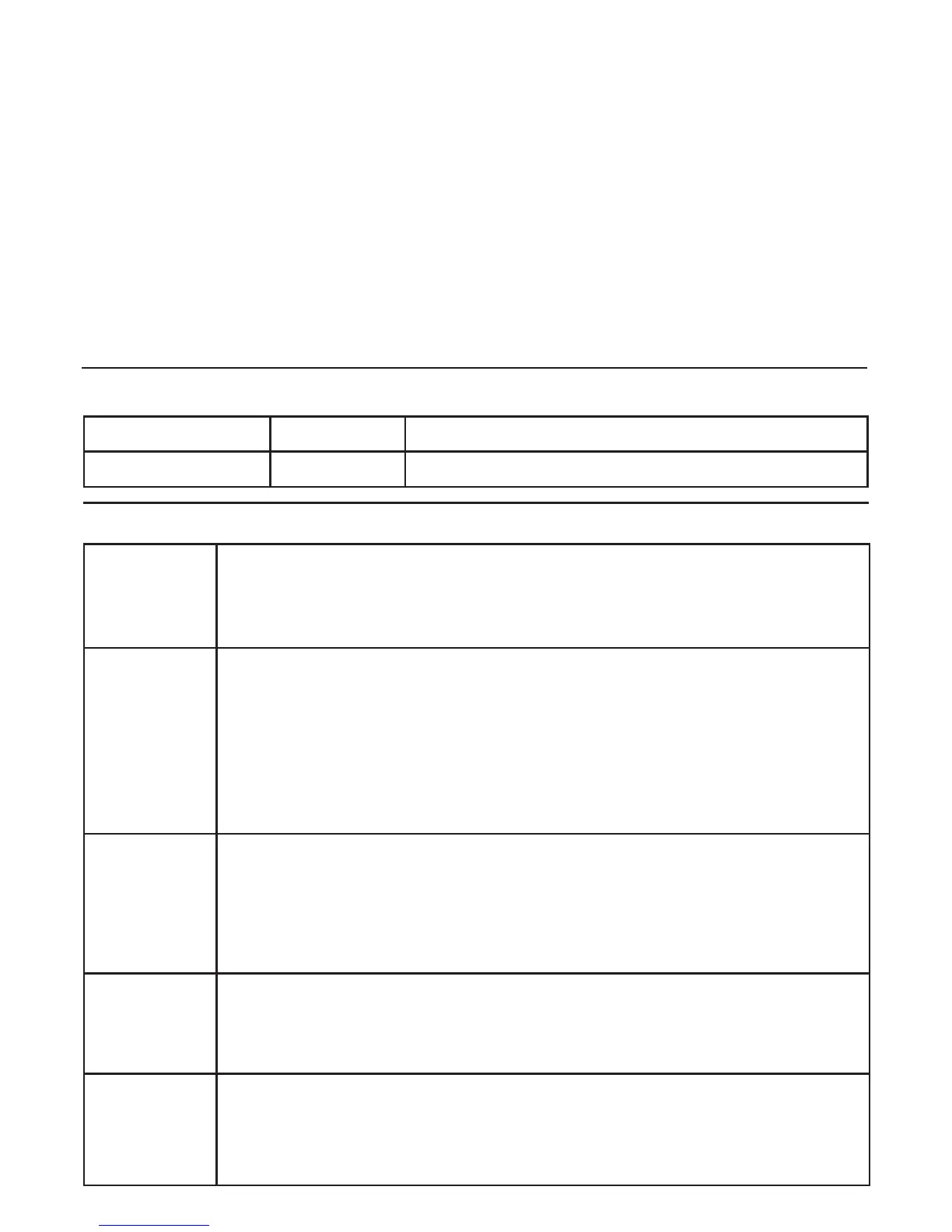

After the rst 50 hours Every 500 ore Every 1000 ore (mean period. Reduce for severe operating conditions)

Oil change Oil change Checking/replacement: Valve assemblies, pumping seals.

START-UP

- Replace the RED transport cap with the cap with a built-in dipstick.

- Check the oil level through the window or using the dipstick and, if necessary, top it up.

- Make sure that all ttings are securely tightened and that the pump feed is open.

- To expel the air present in the pump and make it easier to ll, we recommend you detach the delivery

pipe from the pump or keep the port/s open without any nozzles tted.

- Start the pump for 5/10 seconds until the liquid ows out smoothly from the delivery pipe or applian-

ces; if this does not happen, stop the pump and repeat the operation after a 10-second pause.

- Complete the connections and/or install the nozzles.

- Calibrate or regulate the valves; to prevent tampering, apply lead seals where possible, or paint the

regulating registers so that any tampering can be readily detected.

- All INTERPUMP pumps are tried and tested prior to shipment, the installation engineer is, however,

obliged to test the complete system for an adequate time to check for leaks, overheating, deterioration

in performance or calibration, etc.

MAINTENANCE

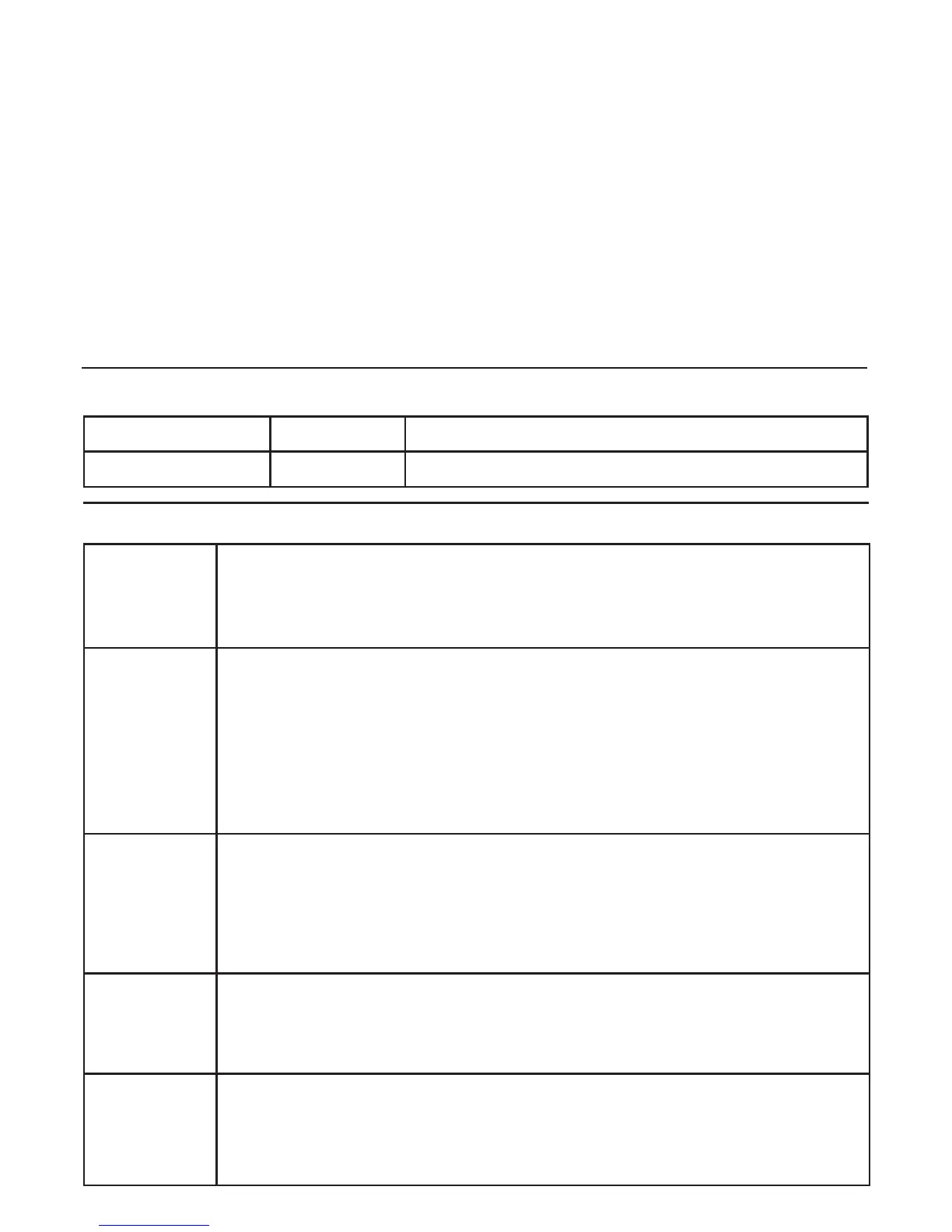

TROUBLESHOOTING GUIDE

At start-up, the

pump makes

no noise

• The pump is not primed and is operating dry, without lubricant.

• The water supply is off.

• The valves are blocked.

• The delivery line is closed and does not let the air ow out of the pump.

The pipes

pulsate in

an irregular

fashion.

• There is Insufficient air suction and/or supply.

• Bends, elbows, ttings on the feed line are slowing down the ow of the liquid.

• The feed lter is dirty or too small.

• The booster pump, if installed, is providing an insufficient pressure and/or capacity.

• The pump is not primed due to an insufficient head, the delivery pipe closing during

priming and/or a valve sticking.

• Worn pressure valves and/or seals and/or transmission problems.

• The pressure regulating valves are not working properly.

The pump

does not give

the rated capa-

city and makes

excessive

noise.

• There is an insufficient supply and/or the number of revolutions is less than the rated

value.

• Excessive leaking from the pressure regulating valve and/or the pressure seals.

• Worn valves.

• Cavitation due to undersized feed pipes and/or lter, insufficient capacity, high water

temperature, clogged lter.

The pressure

supplied by

the pump is

insufficient.

• The port (nozzle) is too large or is worn.

• Excessive leaking from the pressure seals.

• The pressure regulating valve is not working properly and/or the valves are worn.

The pump

overheats:

• The pump is working at an excessive pressure and/or the number of revolutions is

higher than the rated value.

• The oil in the sump of the pump is not at the required level or is not of the recom-

mended type.

• The belt is too tight, the joint or the transmission is not aligned.

Loading...

Loading...