Thicknesser

Model DGI-63D

05

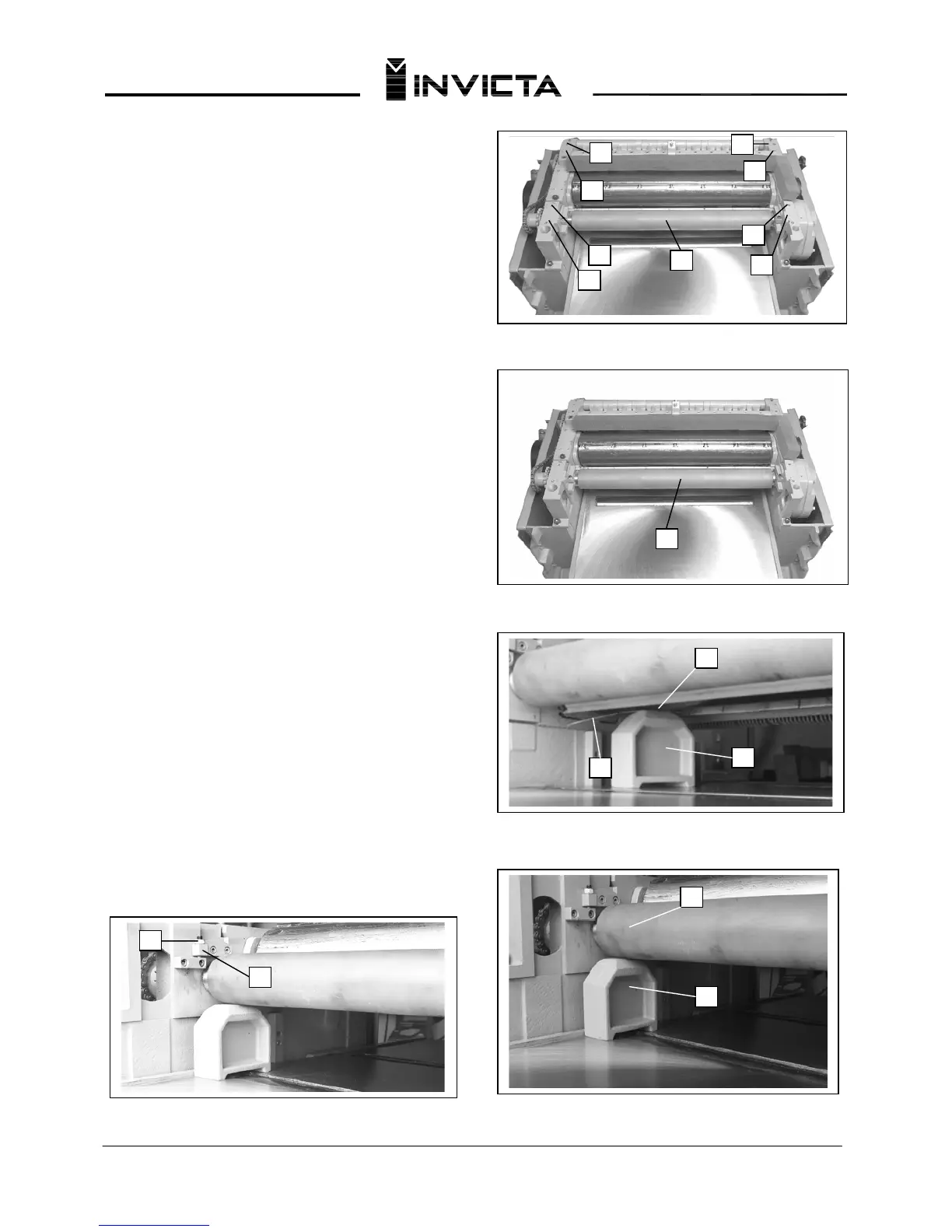

ADJUSTING SPRING TENSION ON

FEED ROLLERS

The outfeed roll (A) Fig. 33, and infeed roll (not visible)

are those parts of your planer that feed the stock while

it is being planed. The feed rolls are under spring

tension and this tension must be sufficient to feed the

stock uniformly through the planer without slipping but

should not be too tight that it causes damage to the

board. The tension should be equal at both ends of

each roll. To adjust spring tension on the infeed roll,

turn screws (B) Fig. 33, right or left until they are flush

with top of casting (C). To adjust spring tension on the

outfeed roll (A), turn screws (D) until they are 2 to 3

complete turns below surface of casting (E).

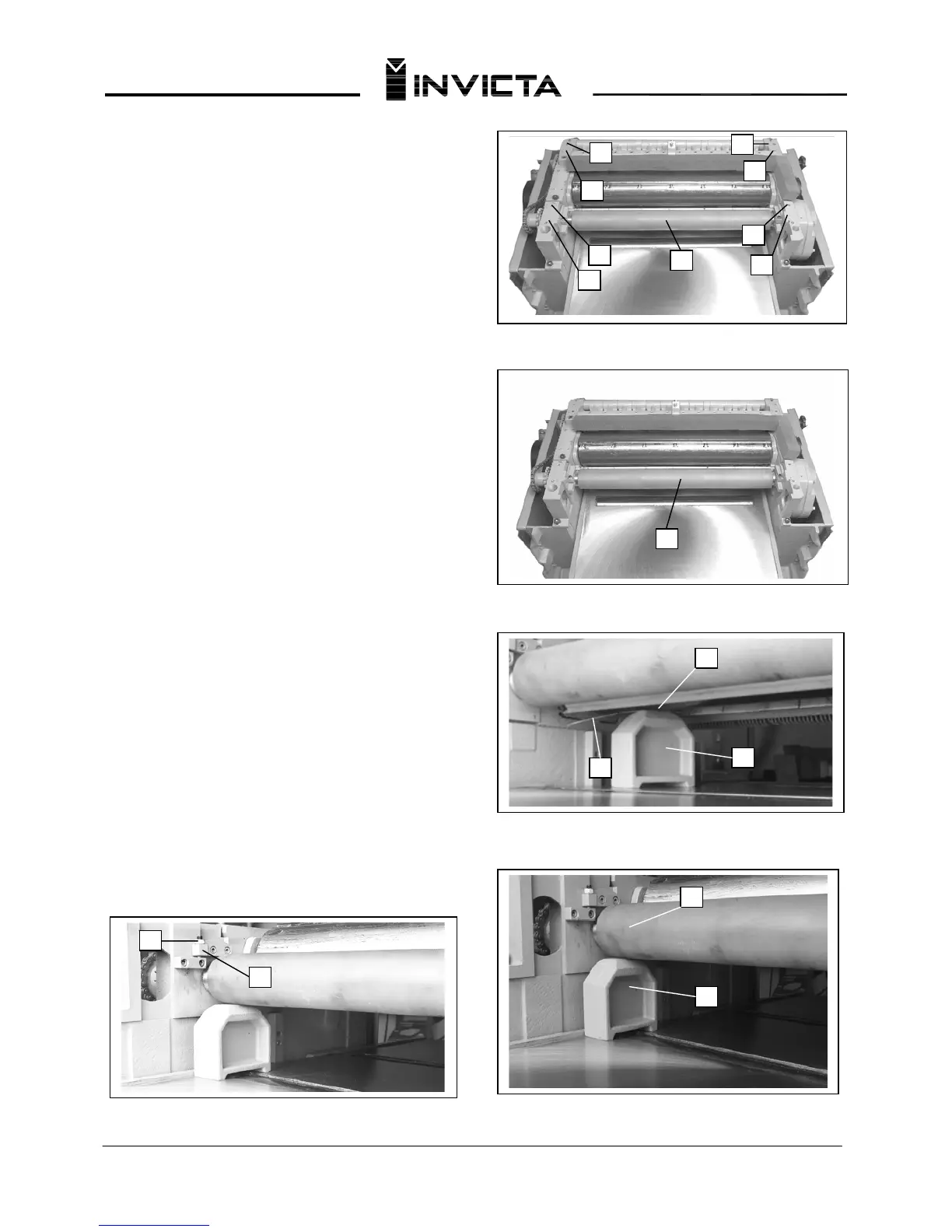

ADJUSTING OUTFEED ROLLER

The outfeed roller (A) Fig. 34, should be .035" below

the cutting circle. To check and adjust the outfeed roll,

proceed as follows:

1. WARNING DISCONNECT MA

CHINE FROM

POWER SOURCE

2. Make certain the knives are adjusted properly as

previously explained under CHECKING,] ADJUSTING]

AND REPLA

CING KNIVES.

3. Place the

guage block (C) Fig. 35, on the table

directly underneath the cutterhead, as shown. Place

a

.035" feeler guage (B) on top of the guage block and

raise the table until the knife (A) just touches the feeler

guage when the knife is at its lowest point. Do not

move the table any further until the adjustment is

completed.

4. Place the guage block underneath outfeed roll (A)

Fig. 36. The feed roll sho

uld just touch the top of the

guage block (C) which would be .035" below the cutting

circle. If a

n ad

justment is necessary, loosen locknut (D)

Fig. 37, and turn adjusting screw (E) until the outfeed

roll just touches the top of the guage block. Repeat at

opposite end of feed roll.

A

C

B

C

B

E

D

D

E

A

C

A

Fig. 33

Fig. 34

B

Fig. 35

A

C

E

D

Fig. 36

Fig. 37

Loading...

Loading...