Procedimiento de higienización

1. HYGIENISATION

Material required:

- Manual valve.

- Dosing cup and connectors.

- Hydrogen peroxide 3% (0.5 l).

- Brush.

- Single use vinyl gloves.

- Soap or detergent for easy rinsing.

- Food lubricant.

- Hydrogen peroxide detection strips.

- Sanitizing spray.

- Paper napkin.

Carry out a sanitization of the equipment during start-

up, when appropriate (whenever there is a risk of con-

tamination of the equipment by manipulation of com-

ponents in contact with water) or with the periodicity

indicated. To do this, follow the steps below:

ATTENTION: The water used during sanitization

must be drinking water (from a public distribution

network complying with the corresponding drin-

king water requirements of RD 140 / 2003, European

Directive 98 / 83 or local legislation in force).

- Open the tap and allow water to recirculate in order to

renew the water inside the equipment.

- Close the inlet valve (1) and open the dispenser tap (2)

to reduce the pressure in the equipment.

HYGIENISATION PROCEDURE

1

3 4

5

2

Closed

Open

- Change the filters and wash them as indicated in the

corresponding section of the Technical Manual of the

equipment. Sanitization must be carried out with the

new pre-filters and after-filters installed and rinsed

previously in an appropriate way (correctly removed

carbon dust from them).

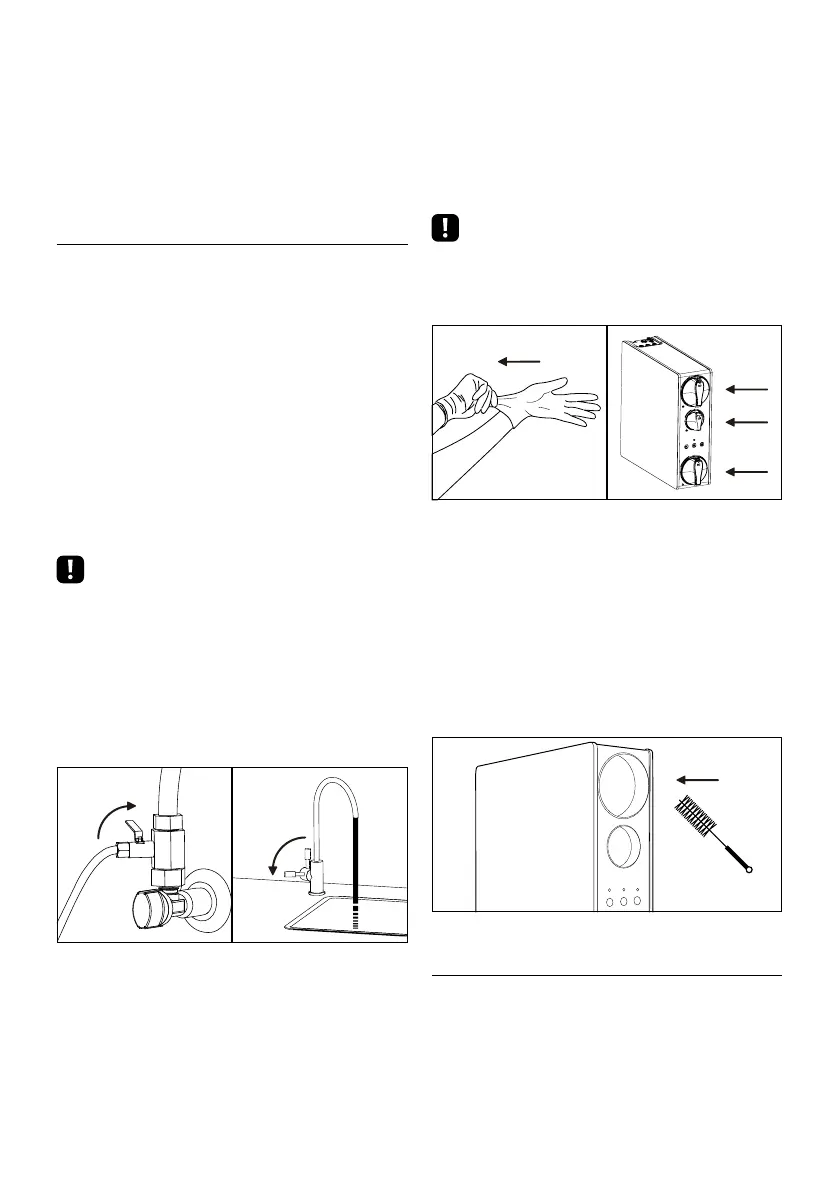

- Use vinyl gloves of only one (3) use to handle sanitizing

products.

ATTENTION: Use extreme caution when handling

filters, membrane and equipment components in

contact with water. Wear disposable gloves or wash

hands as often as necessary to avoid risks of equipment

contamination.

- In order to sanitize the equipment, the filters must be

placed inside their housings (4).

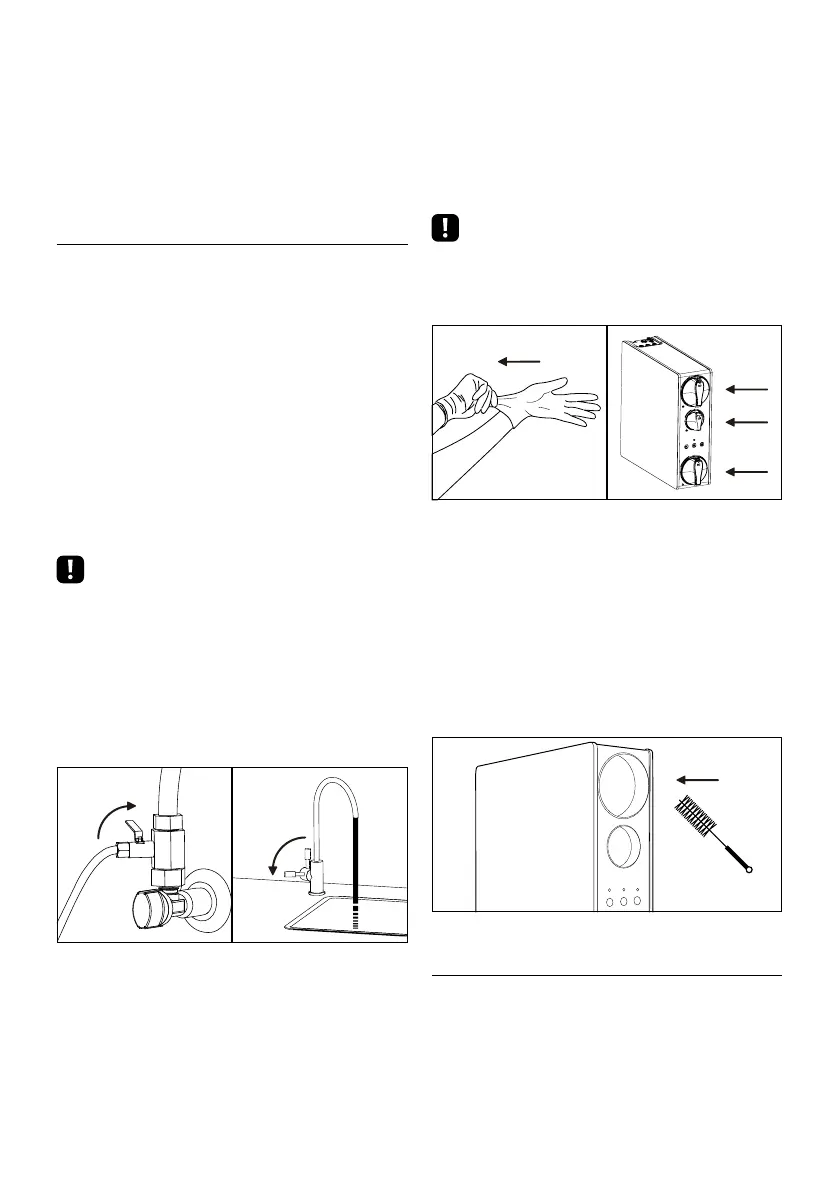

- If you replace a deteriorated membrane or filter at the

end of its useful life, remove the deteriorated membra-

ne for disposal and clean the inside of the housing and

connections with a brush (which must be kept clean

and disinfected) together with soap or detergent that

is easy to rinse (generates little foam) and suitable for

cleaning surfaces in contact with food (5). Afterwards,

rinse the housings and connectors properly, ensuring

that all traces of detergent are removed.

2. PRE-FILTERATION, MEMBRANE AND

POST FILTRATION TREATMENT

- Disconnect the inlet pipe to the unit marked “feed-

in”, and insert the dosing cup between the stopcock

and the water inlet of the unit (6). For greater con-

venience and ease of access during sanitization and

during opening and closing of the input valve, you can

insert, together with the sanitizing dosing cup, a ma-

nual valve in the closed position, which will perform the

same functions as the manual shut-off valve at the inlet

to the equipment.

Loading...

Loading...