- 24 -

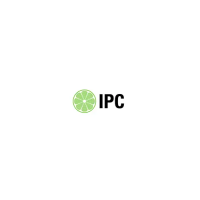

FIG.13

CLEANING THE FUEL

FILTER.

Remove and replace the in-

linefuellter(g.13).

Change it from time to time.

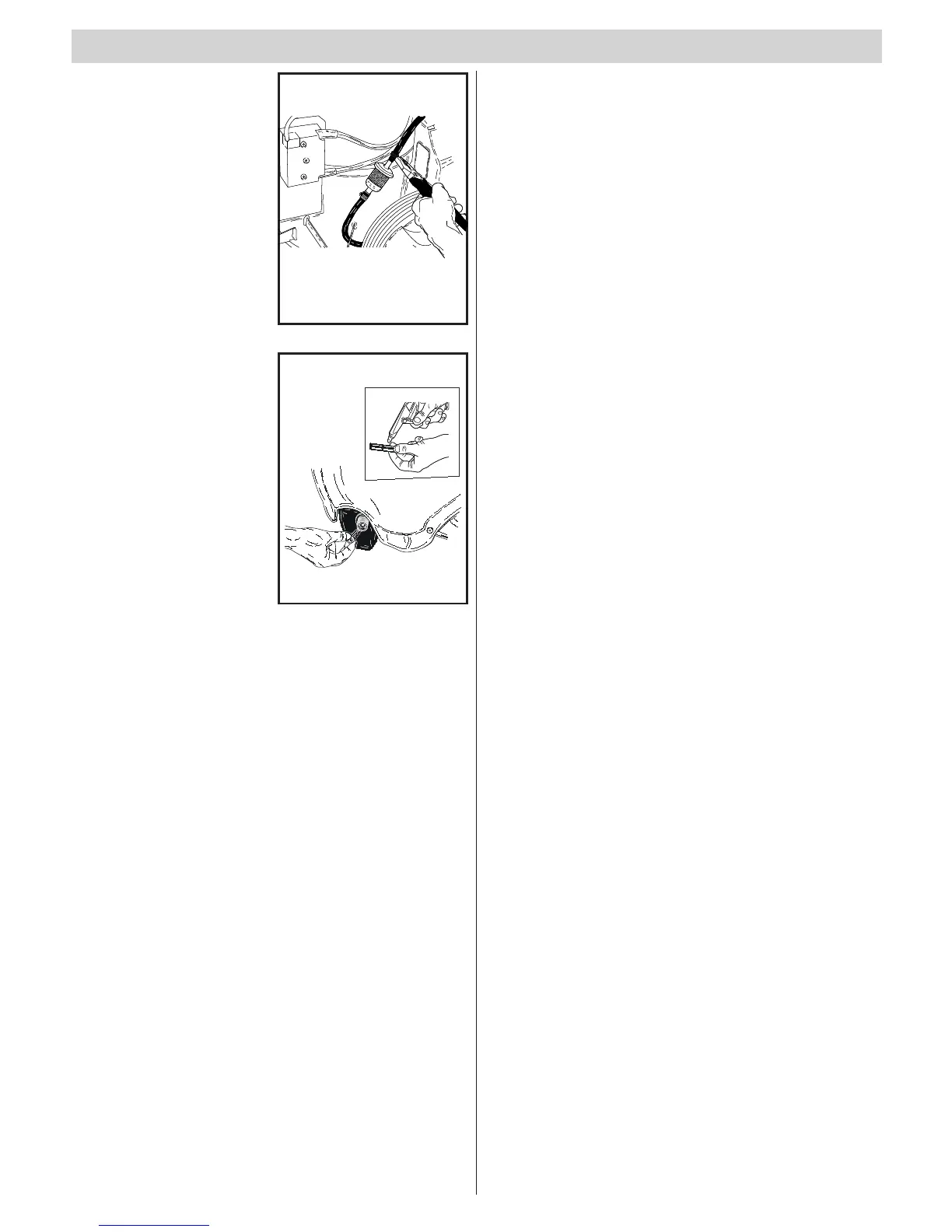

FIG.14

CLEANING THE WATER

FILTER

Clean the water intake lter

regularly and free it from any

impurities(g.14).

CHANGING THE NOZZLE

The high pressure nozzle tted on the lance must be chan-

ged from time to time, as this component is subject to

normal wear during use. Wear may generally be detected

by a drop in the working pressure of the cleaner. To replace

it, consult your supplier and/or dealer for instructions.

DESCALING

Descaling must be carried out from time to time because the

scale present in the water partially deposits inside the hydraulic

circuit and the coil which with time becomes clogged.

Apply to our technical service centre to have the machine

descaled from time to time; this will save you money and

increase the efciency of the cleaner.

TABLE OF ROUTINE MAINTENANCE TO BE PER-

FORMED BY THE USER.

Description of operations:

Check power cable - pipes - high pressure

connectors. Each use

Changeandcleanfuellters. Every100hours

Clean fuel tank. Every 100 hours

Cleanwaterlter. Every50hours

TABLE OF EXTRAORDINARY MAINTENANCE TO

BE PERFORMED BY THE TECHNICAL SERVICE

CENTRE.

Description of operations:

Boiler:

Clean Coil. Every 200 hours

Descale coil. Every 300 hours

Oil change in H.P. pump. Every 500 hours

Clean fuel pump. Every 200 hours

Change fuel nozzle. Every 200 hours

Regulade electrodes. Every 200 hours

Change electrodes. Every 500 hours

Change seals on H.P. pump. Every 500 hours

Change lanze nozzle. Every 200 hours

Calibrate and check the safety

devices. Once a year

Loading...

Loading...