MIG-160ER

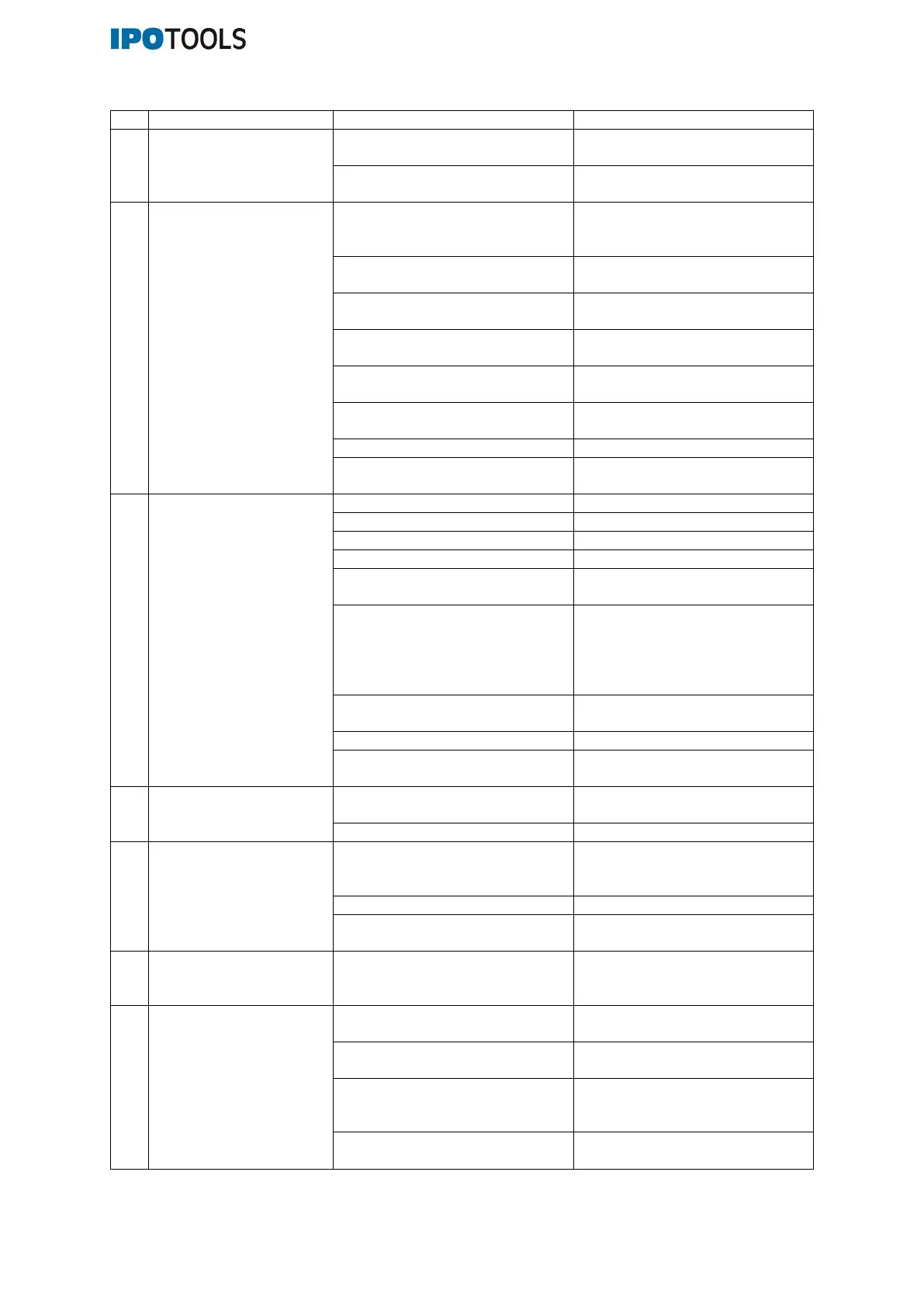

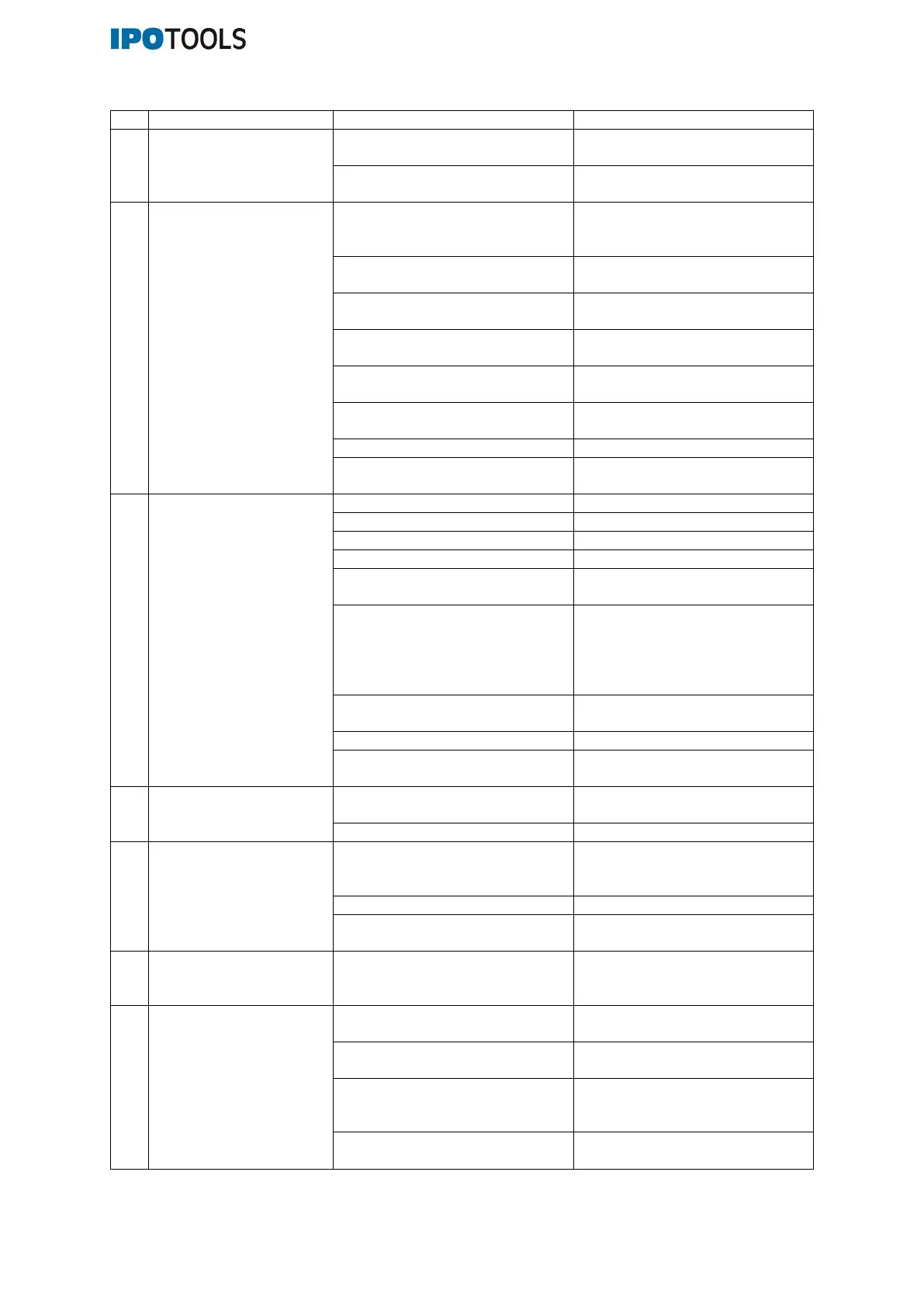

13

1 No function Micro fuse defective Replace micro fuse: 2.5 A (3.15

A)

Wrong power connection Have the connection checked

by a specialist

2 Irregular wire feed Wrong contact pressure on the

feed roller

Set the correct pressure (it must

be possible to block the wire roll

by hand)

Wire guide on the feed motor

not in a line

Bring the feed roller and wire

guide into line

Guide spiral blocked or not

suitable for wire size

Check, possibly change

Badly coiled wire or wire

crossings

Replace the wire roll

Rusted wire or poor quality Replace the wire roll, clean or

replace the guide spiral

Too much tightened mandrel

brake

Release mandrel brake, screw

on

The feed roller is dirty Clean the feed roller

Feed roller worn or not suitable

for wire size

Replace the feed roller

3 Brittle or porous weld

seam

Gas hose connections leaky Check connections

Empty gas bottle Fill up the gas bottle

Gas tap closed Open the gas tap

Defective pressure reducer Check pressure reducer

Solenoid valve defective Test the voltage at the solenoid

valve (220 volts)

Gas nozzle on burner or hose

package clogged

Clean the gas nozzle and

grease the burner with nozzle

grease or spray with nozzle

spray, blow out the hose

package

Draft at the welding point Shield the welding point or

increase the gas flow.

Dirty workpiece Remove rust, grease or paint

Bad wire quality or unsuitable

shielding gas

New welding wire, use suitable

shielding gas or mixed gas

4 Constant gas leakage Solenoid valve defective, foreign

body in the valve

Clean or replace solenoid valve

Hose is not tight Fasten hose clamps

5 No wire feed when the

fan is running

Microswitch in the torch or

control line in the hose package

is defective

Bridging the two small contacts

in the central connection with a

piece of wire

Control board defective Reset the control board

Fine fuse at the control

transformer defect

Replace micro fuse (1 A)

6 Wire feed cannot be

regulated, motor only

Control board defective Reset the control board

7 No welding current

when the feed is

working normally

Main contactor defect Check line contactor, replace if

necessary

Step switch defective Measure the step switch

function

Ground cable or hose package

is not making contact

Check ground cable and hose

package connection and pliers

for contact

Overload protection has turned

on

approx. 10-20 min cooling with

the fan motor running

Loading...

Loading...