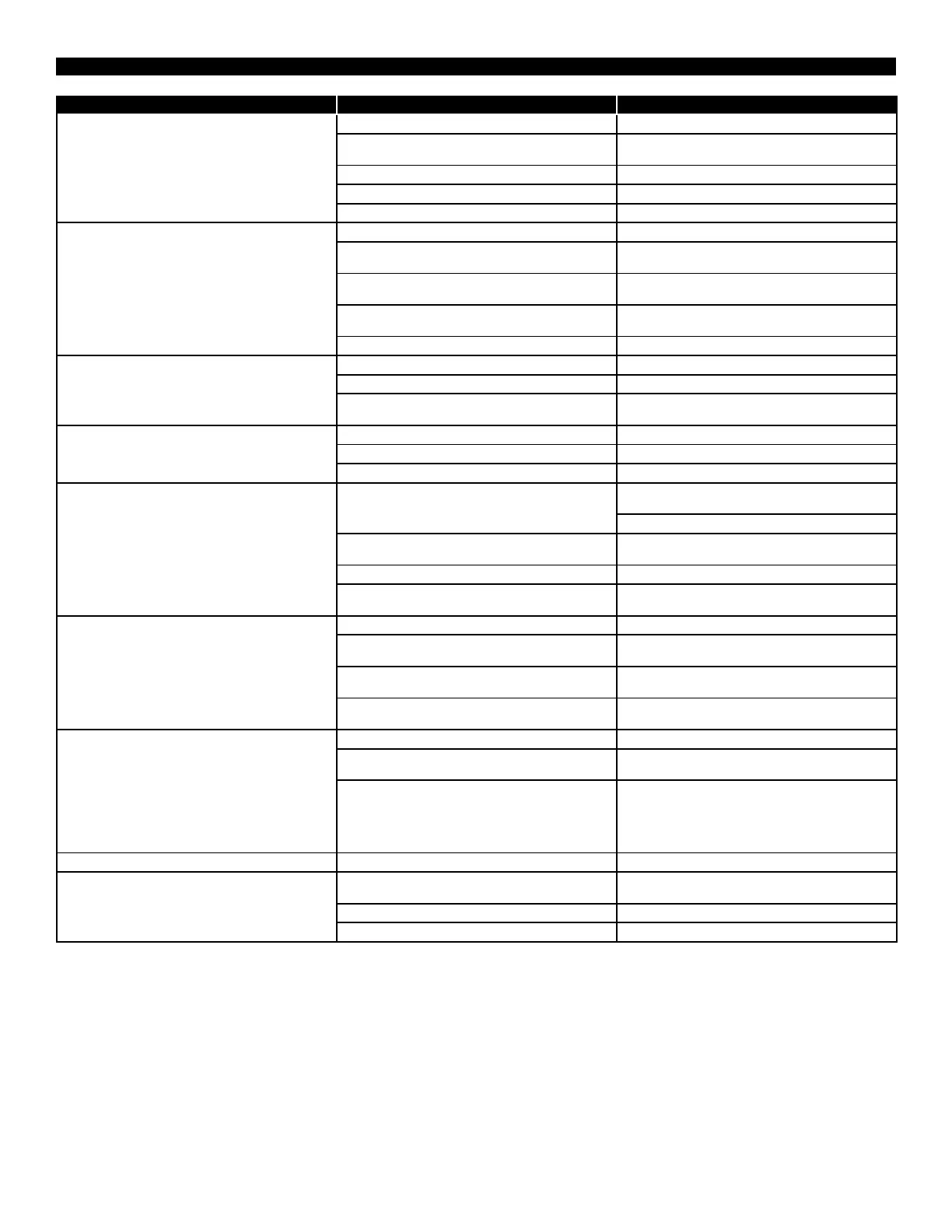

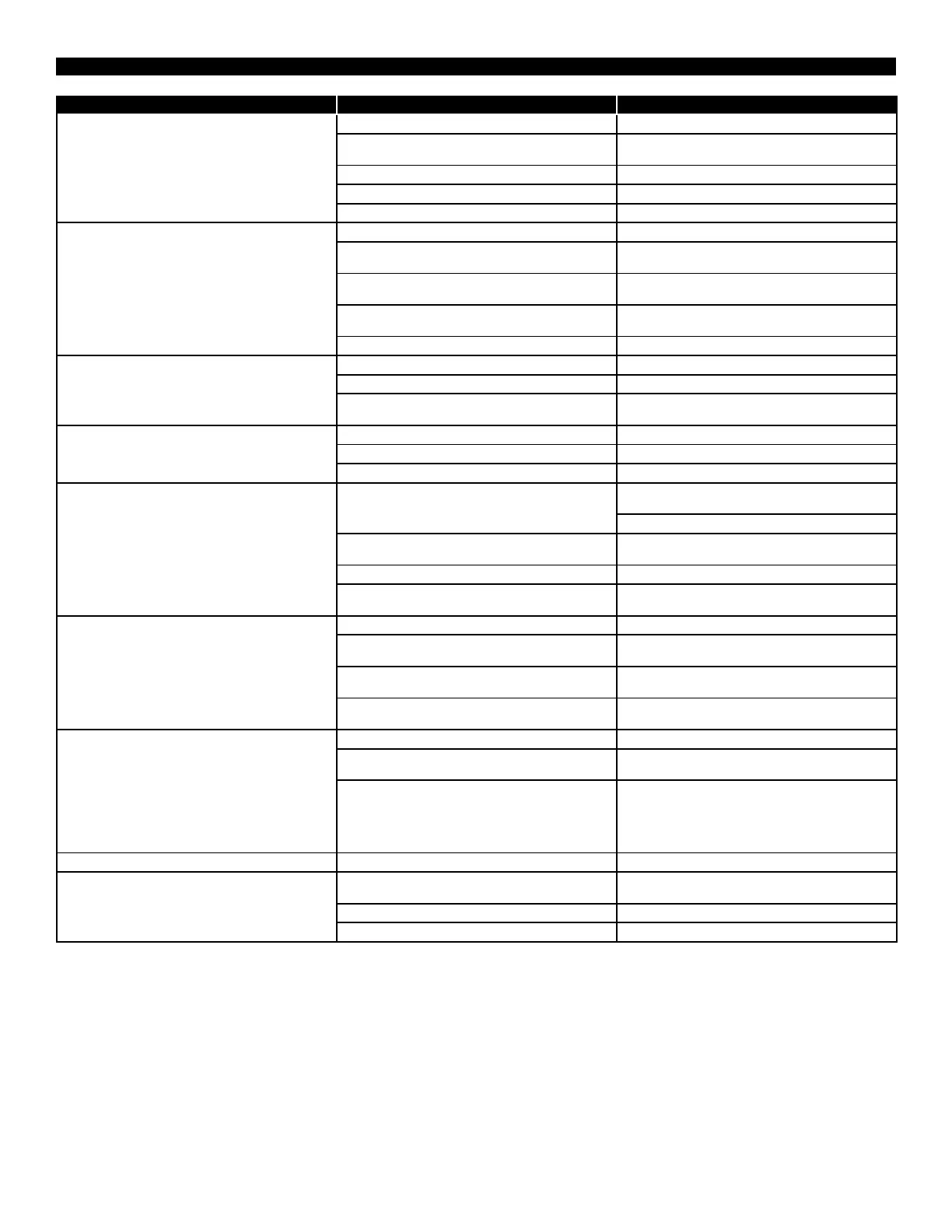

TROUBLESHOOTING

Problem or Symptom Probable Cause Corrective Action

• Tool will not fully drive fastener. » Bit is worn. » Replace bit.

» Power capabilities of the tool have been

exceeded.

» Discontinue use in that application.

» Tool is in reverse. » Switch tool to forward.

» Incorrect bit installed. » Ensure correct bit type and length are installed.

» Depth of drive not set properly. » See pg. 7 for proper adjustment.

• Tool does not advance fastener. » Screw length is improperly set. » See pg. 6-7 for proper adjustment.

» Return spring is weak. » Replace or return to authorized service center

for repair.

» Defective collation material. » Use Senco branded fasteners for optimum

performance.

» Defective slide body. » Replace or return to Senco authorized service

center for repair.

» Screw strip is jammed in guide track. » Ensure strip slides free in guide track.

• Screws “kick-out” or miss-drive during use. » Screw length improperly set. » See pg. 6-7 for proper adjustment.

» Incorrect bit installed. » Ensure correct bit type and length are installed.

» Defective or damaged feed system. » Return to Senco or Authorized service center for

repair.

• Bit will not install. » Bit not properly inserted into drive shaft. » See pg. 6 for proper adjustment.

» Clutch teeth not aligned. » Pulse trigger while holding back release button.

» Not a Senco bit. » Use only the appropriate Senco bit.

• Bit slips off screw or screw is driven at an angle. » Tool slid forward during drive. » If wood nosepiece is used, replace sandpaper

pad.

» Hold tool rmly while driving.

» Tool is misaligned. » Return to Senco or Authorized service center for

repair.

» Bit is worn or broken. » Replace bit.

» Nosepiece is worn or damaged. » Replace or return to Senco authorized service

center for repair.

• Fastener jams. » Screw length improperly set. » See pg. 6-7 for proper adjustment.

» Defective collation material. » Use Senco branded fasteners for optimum

performance.

» Nosepiece damaged or bent. » Replace or return to Senco authorized service

center.

» Screw partially driven into collation material then

feed system released.

» Remove jammed screw with ngers or pliers and

resume use.

• Slide mechanism ”sticks” or returns slowly. » Debris build-up in mechanism. » Clean mechanism.

» Weak return spring. » Replace or return to Senco authorized service

center for repair.

» Bit sticking in collation material. » Use Senco branded fasteners for optimum

performance.

» Always attempt to store screws in cool dry place

before use. Overheated collation can get soft and

cause a delay in feed system return.

• Tool overheats. » Drive application requires too much torque. » Discontinue use in that application.

• Pushing force becomes excessive. » Slide body is worn. » Replace or return to Senco authorized service

center for repair.

» CAM screw is loose or damaged. » Tighten or replace CAM screw.

» Debris build-up in mechanism. » Clean mechanism.

15

Loading...

Loading...