What to check if my IST ATEX HR 600 Distilling equipment starts but does not heat?

- HhmosesSep 6, 2025

If your IST Distilling equipment starts and works but does not heat: - Verify the set temperature T1. - Verify the heating element is functioning.

What to check if my IST ATEX HR 600 Distilling equipment starts but does not heat?

If your IST Distilling equipment starts and works but does not heat: - Verify the set temperature T1. - Verify the heating element is functioning.

What to check if my IST ATEX HR 600 is less productive?

If your IST Distilling equipment has become less productive: - The vapours collecting pipe inside the tank is obstructed and blocks the passage. Check the conditions of this pipe. - The distillation tank is too dirty and the residue left on the walls does not allow the necessary thermic exchange. - If the machine is equipped with vacuum, check the vacuum level reached and check for possible leaks. - Solvent mix has been modified. - Functioning parameters have been modified. - Heating elements are not working properly. Check the electric current (in Amps) during the heating phase. - The ordinary maintenance oil change has not been carried out, causing carbon residuals inside the heating circuit that makes the thermic exchange worse.

What does the 'ALARM WARNING NEXT SERVICE' mean on the IST ATEX HR 600 Distilling equipment?

The 'ALARM WARNING NEXT SERVICE' on your IST Distilling equipment indicates at the end of every cycle that the expiry date for maintenance is near. Press the Stop button to switch the alarm off.

Why is solvent coming out from the vent valve of my IST Distilling equipment?

If solvent is coming out from the vent valve of your IST Distilling equipment: - The vapours collecting pipe is obstructed and does not allow the passage toward the condenser. - The T1 oil temperature set is too high.

What to do if my IST Distilling equipment does not reclaim the whole polluted solvent content?

If your IST Distilling equipment does not reclaim the whole polluted solvent content, verify the correct programming (5.3).

What to do if vacuum does not increase in my IST ATEX HR 600 Distilling equipment?

If vacuum does not increase in your IST Distilling equipment: - Verify the correct tank position. - Check the complete closing of the pneumatic valves. - In case of pneumatic vacuum, check the pump and check the chemical compatibility of the solvent with the seals. - In case of electric vacuum or liquid ring vacuum, check the rotation sense of the motor.

| Type | Distilling equipment |

|---|---|

| Capacity | 600 liters |

| Material | Stainless steel |

| Heating System | Electric |

| Cooling System | Water-cooled |

| Model | ATEX HR 600 |

Emphasizes thorough reading of the manual for safe operation and maintenance.

Guide for operators and technicians on manual usage for safe operation.

Information on hazardous reactions with specific solvents and precautions.

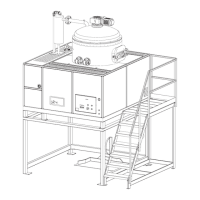

Overview of the Solvent Reclaimer's main components and their functions.

Key specifications including capacity, power, operating temperatures, and standards.

Detailed explanation of the reclaimer's design, function, and intended solvent types.

Defines improper usage and the manufacturer's disclaimer for damages.

Guidance on professional assembly and positioning of optional tanks.

Requirements for the installation environment, including ventilation and ATEX zoning.

Safety guidelines and requirements for making electrical connections.

Overview of the external and internal control panels and their components.

Steps for programming the reclaiming cycle, including default settings.

Navigation through the control panel menus and display information.

Procedure to access and modify parameters using a password.

Options for selecting different reclaiming cycle types (e.g., Automatic, Timed).

Detailed guide on setting temperatures (T1, T2, T3) and cycle times.

Options for managing residual discharge after cycles.

Safety precautions required before performing any maintenance.

General maintenance recommendations and schedule.

Step-by-step procedure for replacing the diathermic oil.

List of alarm messages and their meanings with reset instructions.

Troubleshooting guide for common issues and their resolutions.