Do you have a question about the Iveco N60 ENT M37 and is the answer not in the manual?

Details for engine identification, including commercial code and model number.

Explanation of the product's commercial code and its components.

Description of the model number and its constituent parts.

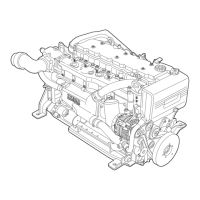

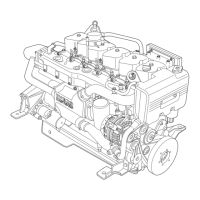

Illustrated identification of key mechanical engine parts and architecture.

Description of the engine's structural design and key internal components.

Details on how air enters and exits the engine for combustion.

Explanation of the engine's closed-loop fresh water cooling system.

Description of the open-loop sea water cooling system.

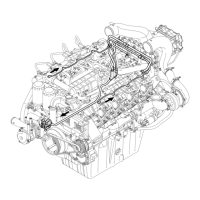

Overview of the engine's oil circulation and lubrication paths.

Identification and description of main fuel line components and piping.

Schematic representation of the engine's fuel supply system.

Detailed performance data including power, torque, and fuel economy.

Key technical data such as bore, stroke, compression, and lubrication details.

Physical dimensions of the engine.

General overview of electrical system layout, wiring harnesses, and component locations.

Simplified block diagram of the engine's electrical system components.

Detailed mapping of wire harness connectors and component connections.

Visual guide showing the placement of electrical components on the engine.

Instructions for setting up the engine's main power supply line.

Technical details and characteristic curves of the engine's alternator.

Technical details and characteristic curves of the starter motor.

Description of the relay box's role and its contained relays.

Breakdown of EDC ECU connectors, terminal functions, and injector connections.

Description of the wiring and connectors for the engine's electro-injectors.

Procedures for grounding electrical components to prevent corrosion.

Explanation of symbols used in diagrams and component code list.

How the ECU indicates anomalies and its general behavior.

Table correlating blink codes with indicated faults and power reduction.

Guide on using the PT-01 instrument, accessing identifiers and fault memory.

How to access and interpret stored faults and measurable parameters.

Key measurement procedures and sensor reference values for diagnostics.

Step-by-step troubleshooting based on blink codes and observed engine symptoms.

Schedule for routine checks and periodic maintenance operations.

Procedures for engine preparation before extended periods of non-use.

Steps for initial engine startup and returning to normal operation.

Introduction to servicing, safety, and spare parts information.

Precautions and instructions for working on the fuel injection system.

Procedures for replacing electro-injectors, fuel system piping, and valves.

Steps for cleaning heat exchangers and removing shaft sealing rings.

Procedures for fitting housing/gearbox and decoupling sea water components.

Recommended sequence for removing the engine from its vessel.

Catalog of special tools with their corresponding numbers and definitions.

Core engine specifications relevant for overhaul procedures.

Tables detailing critical clearance measurements for engine parts.

Procedures for bench overhaul, cylinder unit checks, and repairs.

Main data and checks for camshafts, bushes, and their housings.

Instructions for handling, measuring, and fitting connecting rods and pistons.

Steps for overhauling the cylinder head and its valves, including seats and springs.

Comprehensive list of torque specifications for various engine components.

General safety rules and precautions for maintenance operations.

Guidelines to prevent personal injury during engine work.

Specific safety rules to follow when performing maintenance.

Precautions for handling fluids, waste disposal, and environmental protection.