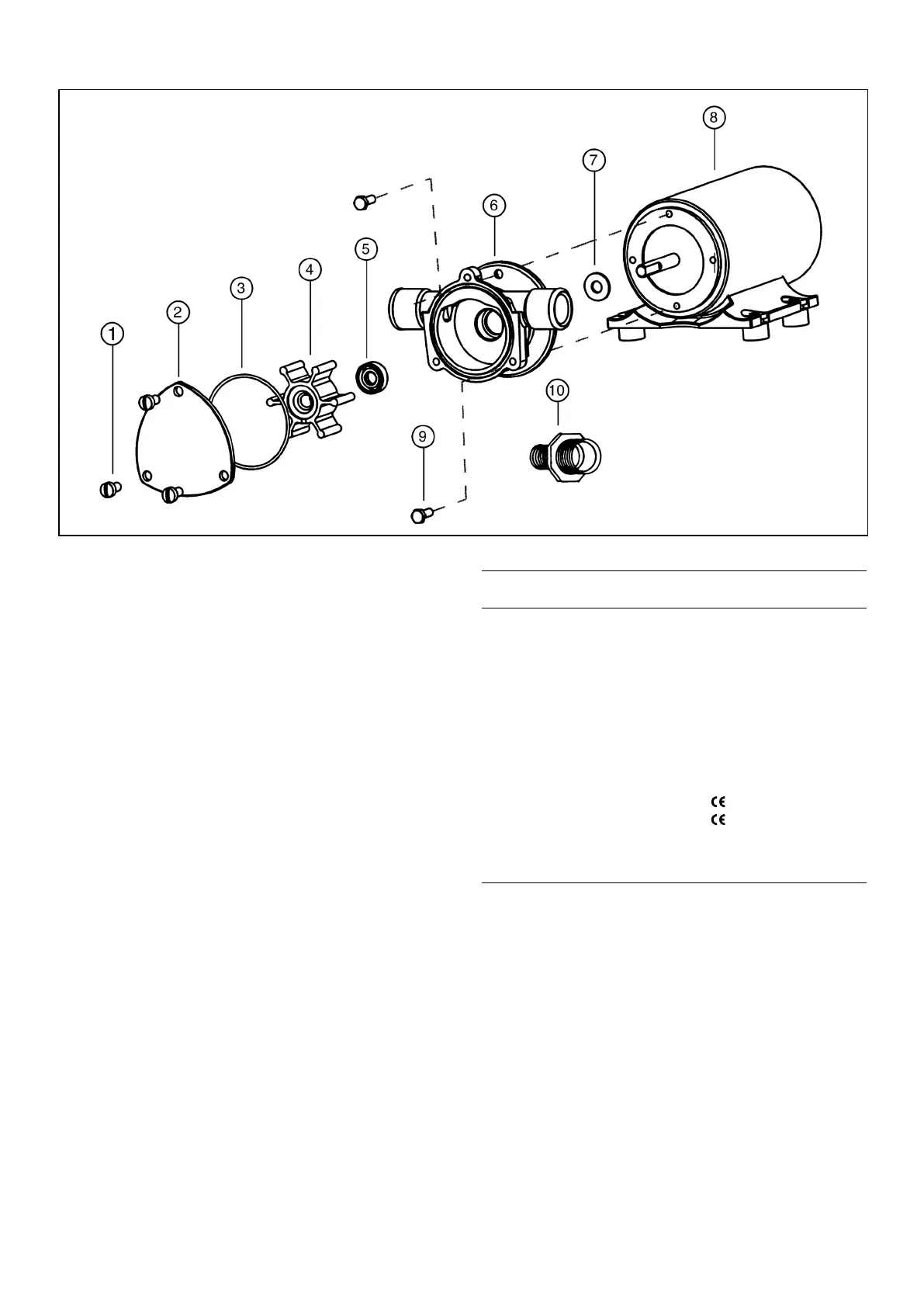

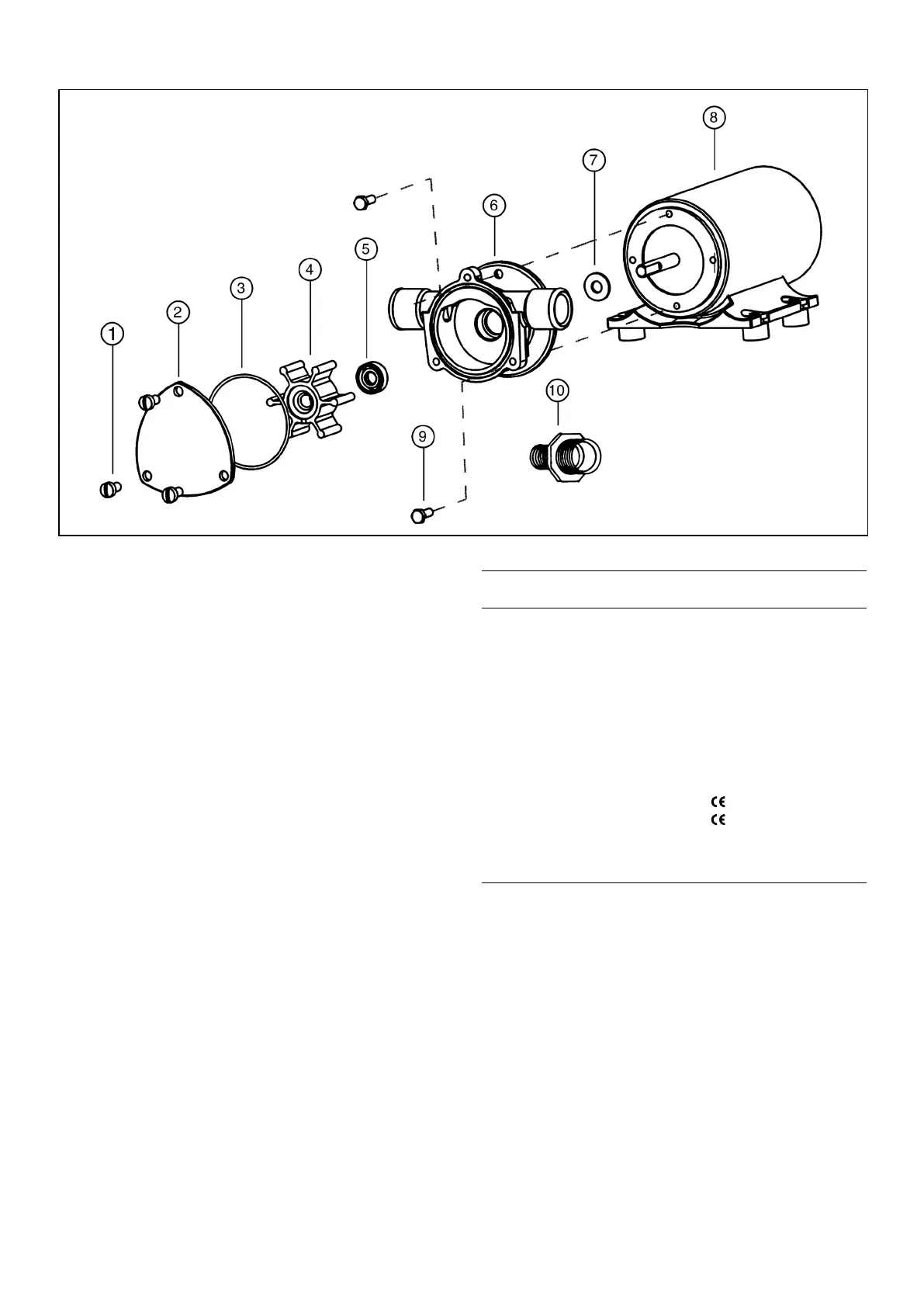

PARTS LIST

Part

Key Description Qty. Number

1 Screw Kit (End Cover) 1 91004-0090

(4 screws/kit)

2 End Cover 1 18647-0000

3 O-Ring* 1 18753-0660

4 Impeller* 1 6303-0003

5 Seal* 1 18753-0384

6 Body

†

1 18645-0000

7 Slinger 1 6342-0000

8 Motor 1

Model 18670-0123 12V 18753-0050

Model 18670-0923 12V 18753-0659

Model 18670-0943 24V 18753-0051

9 Screw (Pump to Motor) 2 98019-0020

10 Port Adapter Kit (2 each) 1 18753-0103

Service Kit 90061-0031

* Parts Contained in Service Kit.

† When replacing a pump body that uses a round end cover (3 hole

pattern) it is also necessar y to replace the end cover, screws and

replace the gasket with an O-ring (order keys 1, 2 & 3).

MAINTENANCE

Check wires and connections to be sure corrosion is

not adding additional resistance to the motor circuit

and causing a low voltage condition at the motor. Low

voltage can inhibit motor from starting and cause

fuse to blow. Full voltage should be available to prevent

motor damage.

NOTICE: If pump is idle for extended periods, the impeller

may stick to the pump body, preventing motor rotation

and causing blown fuses. To correct, remove end cover

and impeller, clean body and impeller, then lubricate with

water or small amounts of grease before assembly.

If pump is to be in freezing temperatures, drain by

loosening end cover screws.

A Service Kit, or at least spare impellers, should be

carried aboard to be assured of pumping capability.

DISASSEMBLY

1. Remove end cover screws, end cover and O-ring.

2. Withdraw impeller.

3. Loosen and remove two slotted hex screws, which

attach body to motor.

4. Tap body lightly between ports and remove body

from

motor.

5. With a 1/2" diameter dowel, push against the shaft

seal from back (motor) side of the body to dislodge

it from the seal bore.

NOTE: Do not tamper with or disassemble motor.

ASSEMBLY

1. Lubricate seal with water and position it in seal bore

with lip, or hollowed-out side of seal, pointing

towards the impeller bore. With a 1/2" diameter

dowel, push against the shaft seal into its bore until

it contacts the bottom.

2. Lubricate motor shaft and install body on motor.

3. Lubricate impeller bore and, aligning flat in impeller

with flat on motor shaft, install impeller with clock-

wise rotary motion.

4. Install O-ring, end cover and screws.

EXPLODED VIEW

Loading...

Loading...