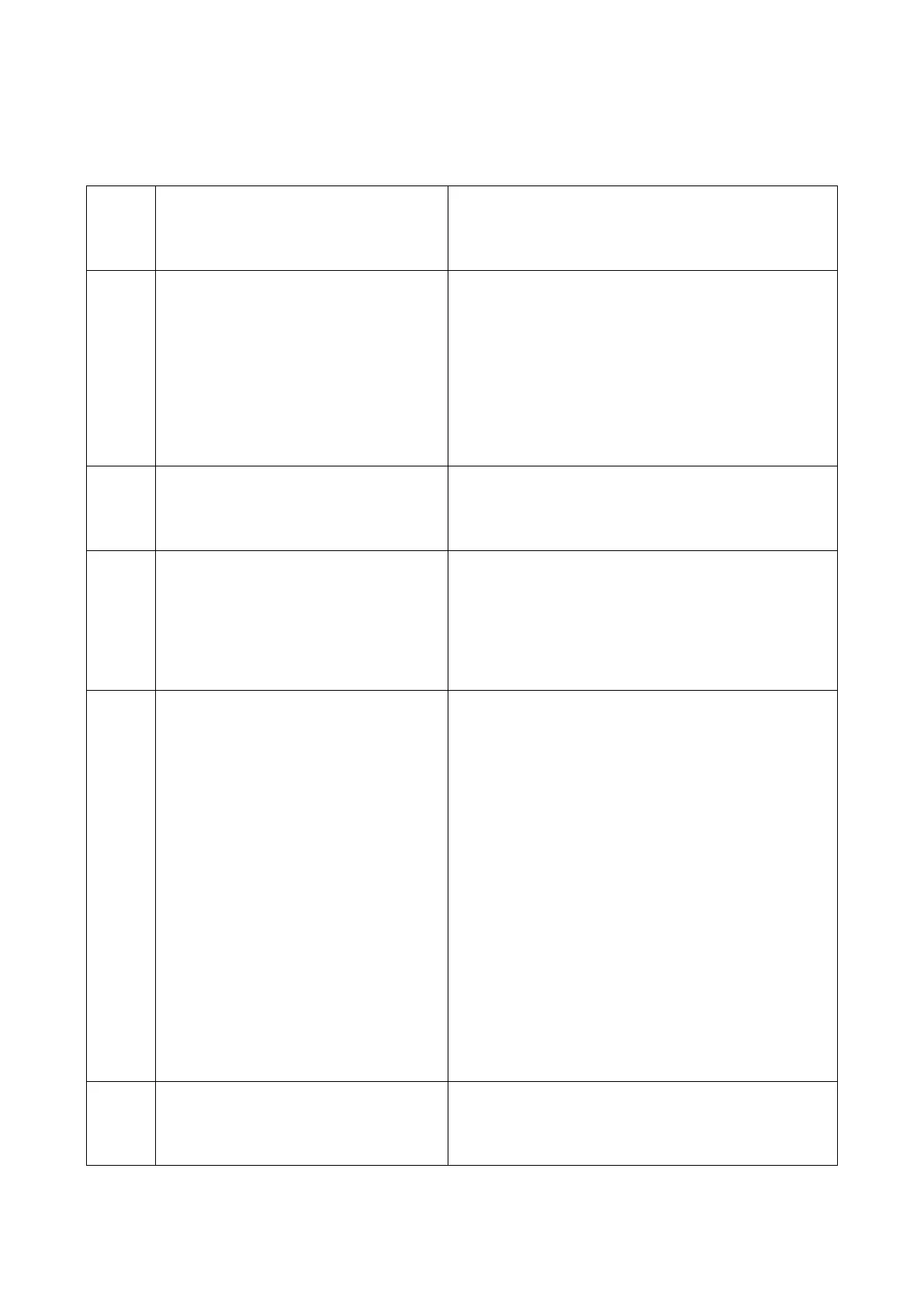

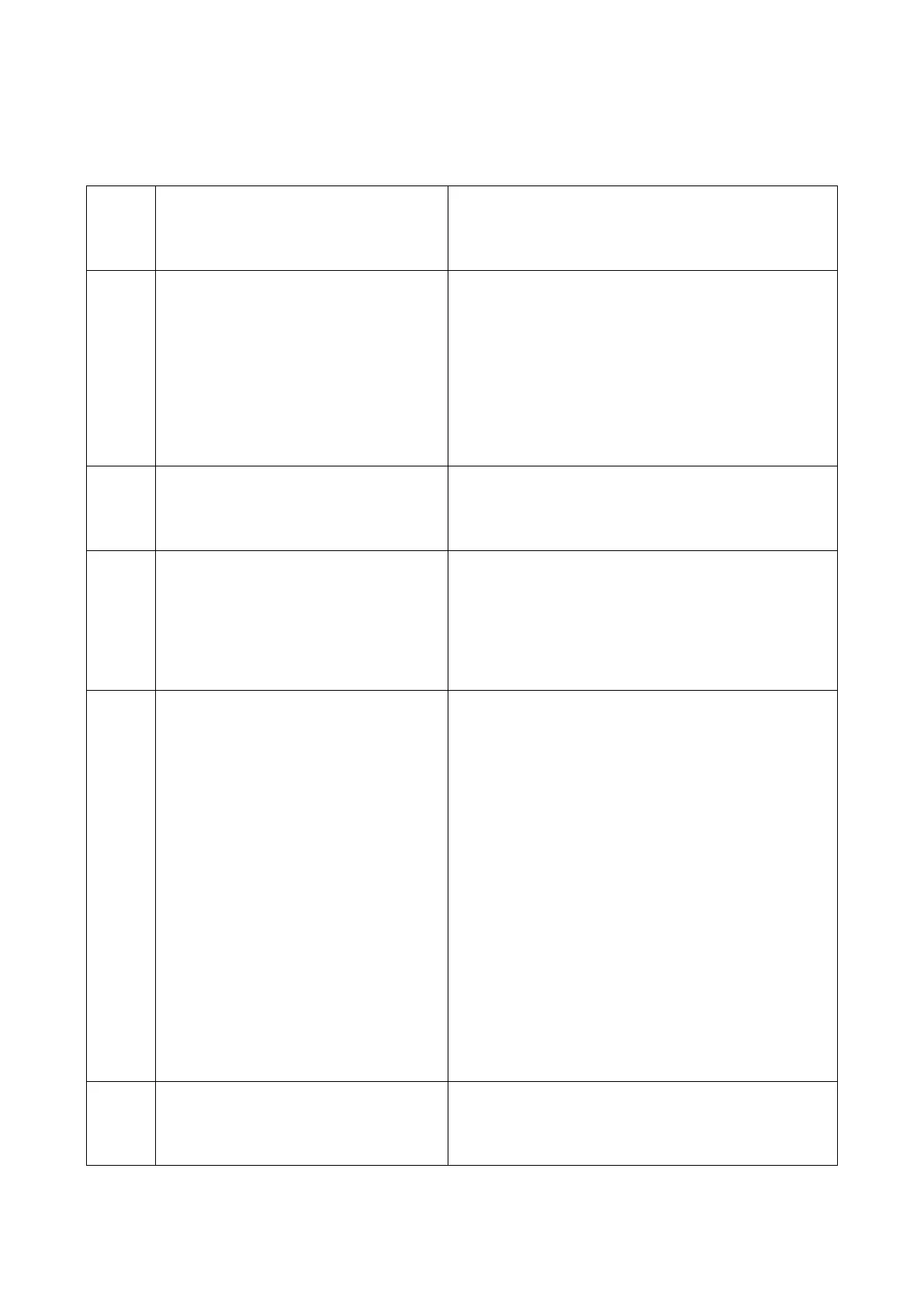

11

3:错误代码表 ERROR CODES TABLE

1) 电力模块错误代码

Power Module is faulty.

2) 不正常过电流或过电压

Abnormal over current or

voltage.

模块驱动出力与机头出力将全部关闭

The module drive output with head power output will

be shutting.

等待电源重新开启/复位(请仔细检查电源板各项机

能)

Waiting for the power boad of the each

function(Please check the power of each function)

步进电机通讯异常

Stepper motor communication error

检查步进电机驱动板与主控板的通讯线

Check stepper motor driver board and the control

board communication lines

步进电机感应未到位或异常

Stepper motors are not in place or

abnormal induction

1.检查步进电机的感应器(光电开关)是否异常

Check the stepper motor sensor (photoelectric

switch) is abnormal

2.步进电机的机械结构是否到位。

Stepper motor mechanical structure is in place.

a)马达插头配线接触不良导致不转

Bad connection at the motor

connector.

b)定位器信号异常。

Locator signal abnormality.

c)车头机构死锁或马达皮带异物卷入

卡死。

Machine locked or object stuck in

the motor pulley.

d)加工物过厚,马达扭力不足无法贯

穿。

Sewing material is too thick.

e)模块驱动出力异常。

Module output is abnormal.

模块驱动出力与车头出力将全部关闭。

System will be shut down until the power resets on.

等待电源重新开启/复位。(请检查车头是否卡住或定

位器、马达、模块驱动等信号是否异常)

(Please check the machine head connectors,

Locators motor and Module output signal is

abnormal or not.)

定位器信号异常

Locator signal abnormality.

检查上下定位信号是否正常,皮带轮是否过于松动。.

Please check the positioning signal or the condition

of pulley.

Loading...

Loading...