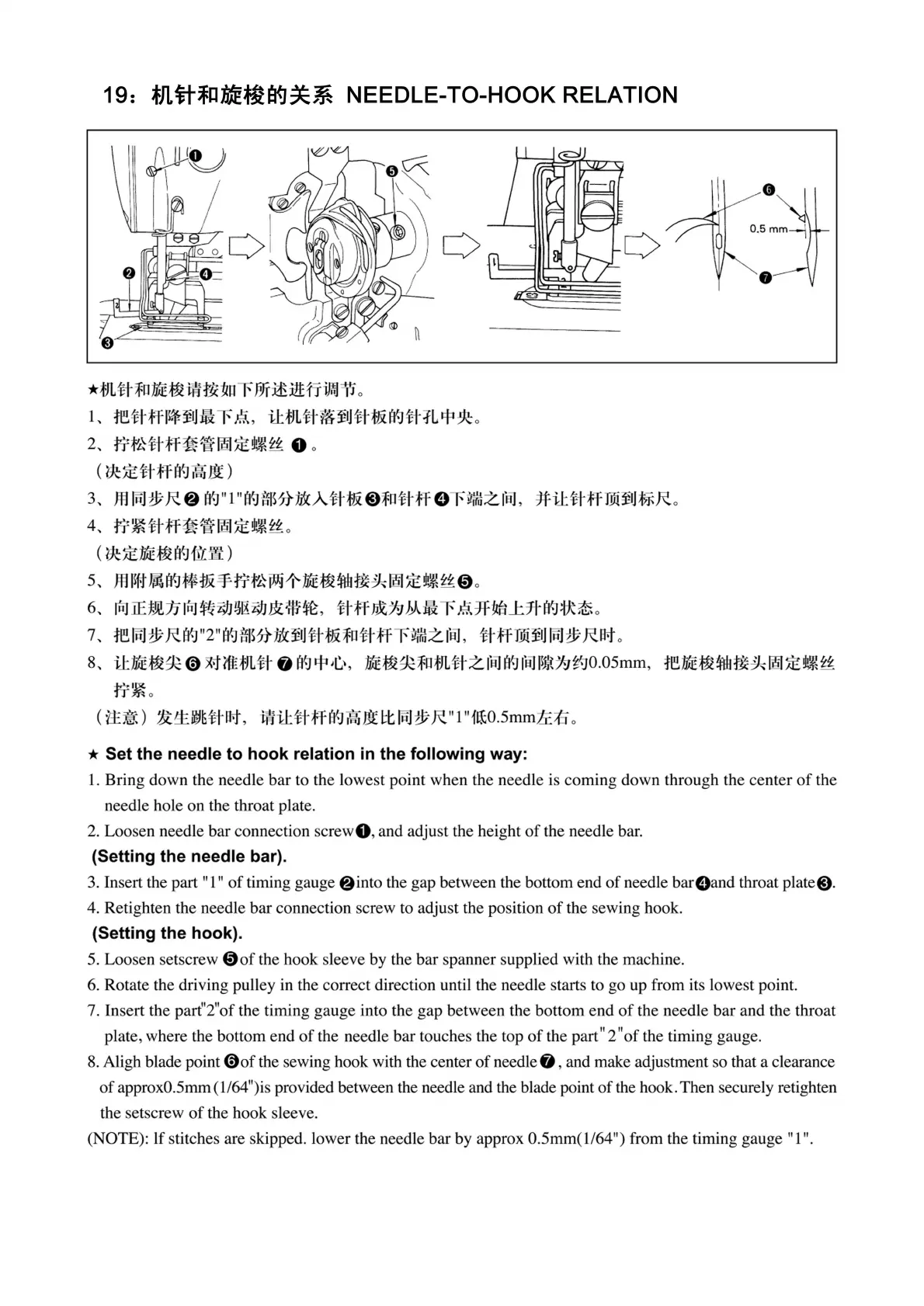

19:

机针和旋梭的关系

NEEDLE-TO-HOOK

RELATION

叫几针和旋梭请按如下所述进行调节

。

1

、把针杆降到最下点,让机针落到针板的针孔中央

。

2

、拧松针杆套管固定螺丝

@

。

(决定针杆的高度)

。

3

、用同步尺

@

的

"1"

的部分放入针板

@

和针杆

@

下端之间,并让针杆顶到标尺

。

4

、拧紧针杆套管固定螺丝

。

(决定旋梭的位置)

5

、用附属的棒扳手拧松两个旋梭轴接头固定螺丝

@

。

6

、向正规方向转动驱动皮带轮,针杆成为从最下点开始上升的状态

。

7

、把同步尺的

"2"

的部分放到针板和针杆

下端之间,针杆顶到同步尺时

。

8

、让旋梭尖

@

对准机针

@

的中心,旋梭尖和机针之间的问

I~

为约

O

.

05mm

,把旋梭轴接头固定螺丝

拧紧

。

(注意)发生跳针时,请让针杆的高度比同步尺

"1"

低

O.5mm

左右。

食

Set

the

needle

to

hook

relation

in

the

following

way:

1.

Bring

down

the needle b

ar

to the lowe

st

point when the needle is

coming

down

through the center

of

the

needle hole on the throat plate.

2. Loo

se

n needle bar connection screwO , and adjust the height

of

the needle bar.

(Setting

the

needle

bar).

3. Insert the part

"1"

of

timing gauge

@in

to the gap between the bottom end

of

needle barÐ and throat plate

@}.

4. Retighten the needle

bar

connection screw to adjust the position

of

t

he

sewing hook.

(5etting

the

hook).

5. Loosen setscrew 0

0f

the hook sleeve

by

the

bar

spanner supplied with the machlne.

6. Rotate the driving pulley in the correct direction until the needle starts to

go

up from its lowe

st

poin

t.

7. Insert the

pa

rt"

2"of

the

tirning gauge into the

gap

between the bottom

end

of

the needle

bar

a

nd

the throat

plate

, where the bottom end

of

the needle bar touches the top

of

the part" 2"

of

the timing

ga

u

ge

.

8.

Aligh blade point 0

0f

the sewing hook with the center

of

needle Ö , and make adjustment so that a clearance

of

approxO.5mm (1I64")is provided

betw

臼

n

the needle and the blade point

of

the hook. Then securely retighten

the setscrew

of

the

hook

sleeve.

(NOTE):

lf

stitches are skipped. lower the needle bar by approx O.5mm(

1I

64")

from the timing gauge

"1

".

Loading...

Loading...