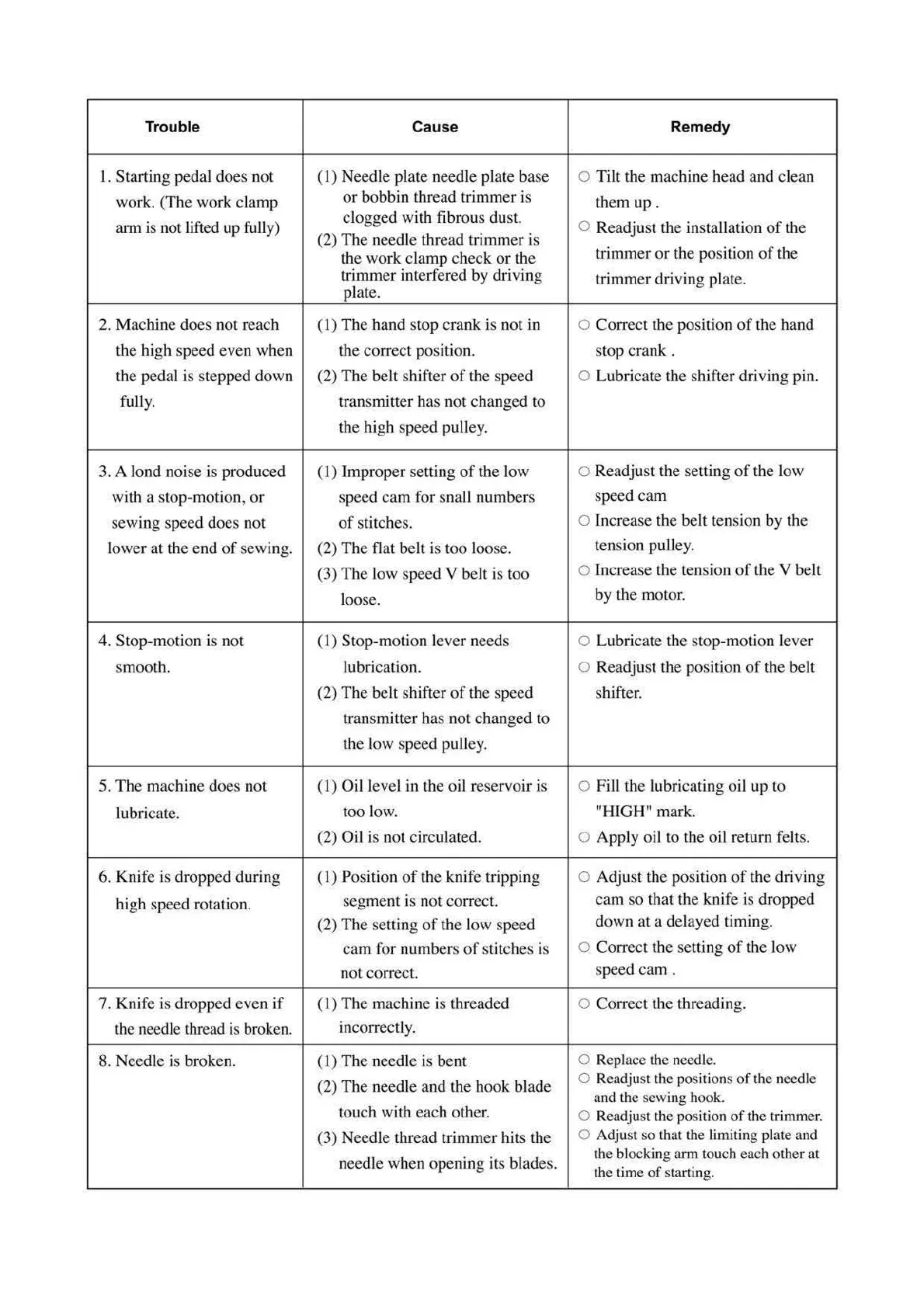

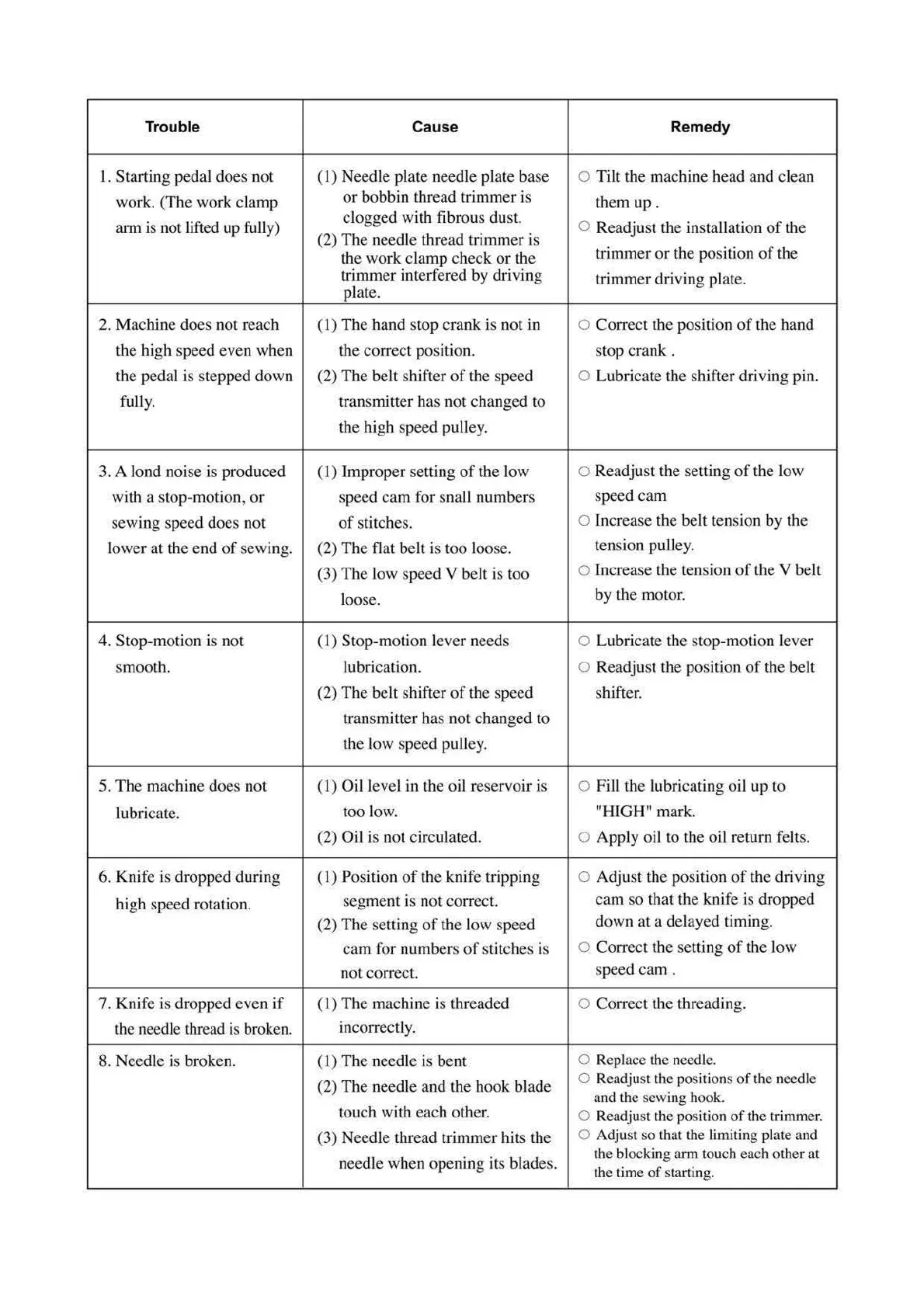

Trouble Cause Remedy

1.

Starting pedal does not (1) Needle plate needle plate base 0 Tilt the machine head and clean

work. (The work clamp

or

bobbin thread trimmer is

them

up.

arm is not lifted up fully)

clogged with fibrous dust.

0 Readjust the

in

stallation

of

the

(2)

The

needle thread trimmer

is

the work clamp check

or

the

trimmer

or

the position

of

the

trimmer interfered by driving

trimmer driving plate.

plate.

2. Machine does not reach ( 1) The hand stop crank is not

in

0 Correct the position

of

the hand

the high speed even when the correct position. stop

crank.

the pedal is stepped

down

(2)

The

belt shifter

of

the speed 0 Lubricate the shifter driving pin.

fully. transmitter bas not changed to

the high speed pulley.

3. A lond noise is produced

(I)

Improper setting

of

the low 0 Readjust the setting

of

the low

with a stop-motion,

or

speed cam for snall numbers

speed cam

sewing speed does not

of

stitches.

0 Increase the belt tension by the

lower

at

the end

of

sewing. (2)

The

flat belt

is

too loose.

tension pulley.

(3) The low speed V belt is too

0 Increase the tension

of

the V belt

loose.

by the motor.

4. Stop-motion is not

(I)

Stop-motion lever needs 0 Lubricate the stop-motion lever

smooth. lubrication. 0 Readjust the position

of

the belt

(2)

The

belt shifter

of

the speed shifter.

transmitter has not changed to

the low speed pulle

y.

5.

The

machine does not (1) Oil level

in

the oil reservoir is 0 Fill the lubricating oil up to

lubricate.

too low. "HIGH" mark.

(2) Oil is not circulated.

0 Apply oil to the oil return felts.

6.

Knife is dropped during (1) Position

of

the knife tripping 0 Adjust the position

of

the driving

high speed rotation.

segment is not correct.

cam so that the knife is dropped

(2)

The

setting

of

the low speed

down at a delayed timing.

cam for numbers

of

stitches is

o Correct the setting of the low

not correct.

speed

cam.

7. Knife is dropped even

if

(

1)

T

he

machine is threaded 0 Con·ect the threading.

the needle thread is broken.

incorrectly.

8. Needle

is

broken.

(1

) T

he

needle is bent

0 Re

plac

e

th

e n

ee

dl

e.

(2)

The

needle and the book blade

0

Re

a

dju

st

th

e

po

s

iti

ons

of

th

e needle

and

the

sewing

ho

ok.

touch w.

ith

each other.

0 Readjust

th

e

po

s

ition

of

th

e trimme

r.

(3) Needle thread trimmer hits the

0

Adju

st so

that

the

limiting

pl

ate

and

needle when opening its blades.

the

blocking arm

touch

each

other at

th

e

Lim

e

of

starting.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...