2 Speed Boat Trailer Winch Owner’s Manual

5

Winches are not intended (1) for the movement of people and (2) as a load securing device for boats on trailers

(T) +61 (0)8 8243 9100 (F) +61 (0)8 8243 9185 Toll Free Sales: 1 300 135 935

Email: sales@advansa.com.au Web: www.advansa.com.au

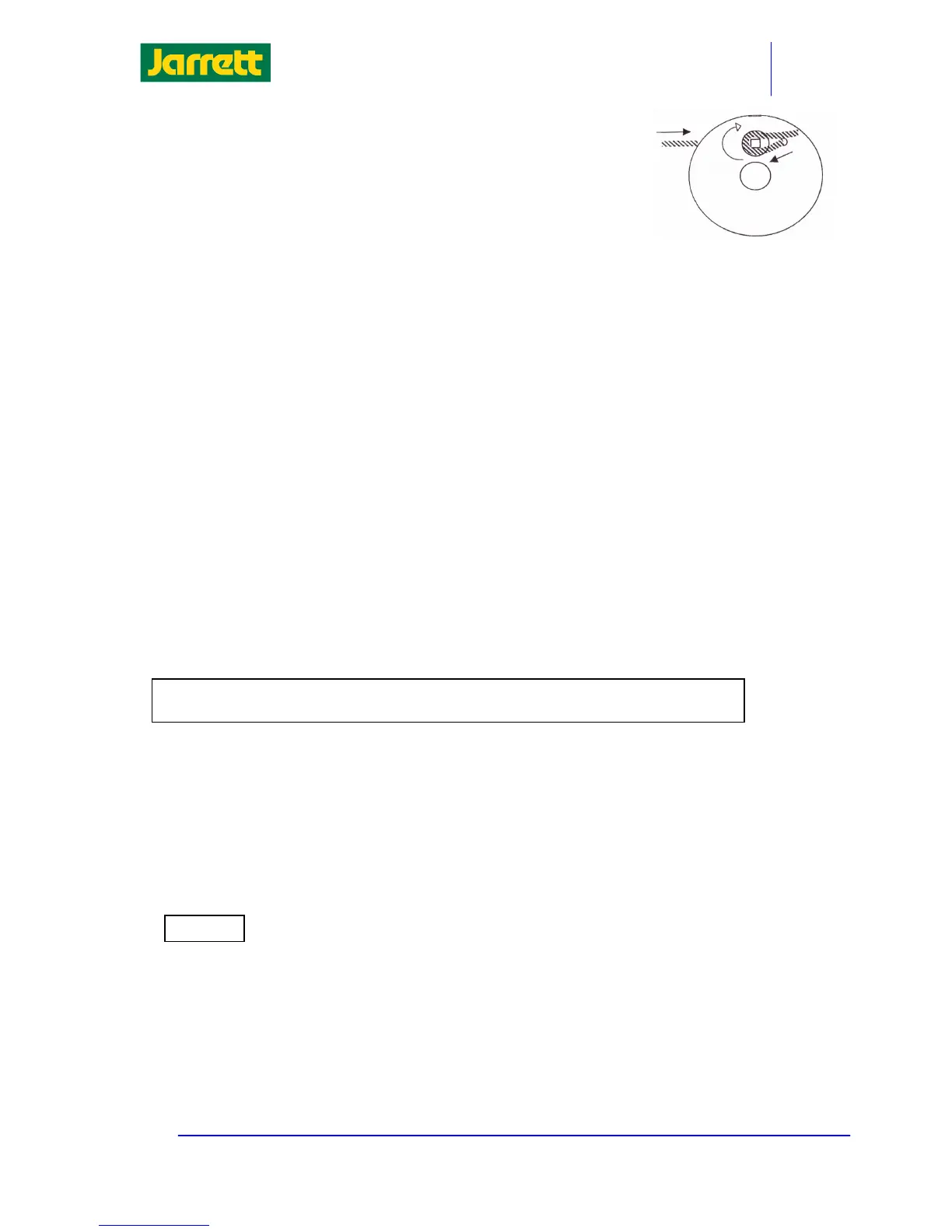

Instruction for securing a cable to a winch using a single bolt fitting

1. Place the cup headed bolt into the square hole with the head on the inside of the drum assembly.

2. Screw on the combination nut and washer only 2-3 threads.

3. Tape the cable end using 50mm – 70mm of plastic tape. This is to stop the cable end

from fraying and causing injury in use.

4. Feed the taped end of the cable through the round hole of the drum flange (disc) from inside the drum

and double back to loop the cable under the bolt, behind the washer and back towards the round hole.

5. While holding the cable in place under the nut with the left hand, pull the cable tight with the right hand.

6. Using the thumb of the left hand hold the cable in place inside the drum and tighten the nut to secure

the cable in place. View from outside the drum

showing cable flow

Turn the handle to wind the wire cable onto the winch drum. Uniformly wind the wire cable onto

the winch drum by holding the wire cable taut.

Instruction for securing fibre rope to winch – Note: Fibre rope to be ≤ Ø7mm

1. Take the winch drum with the gear facing the assembler and the free end of the rope and wrap three turns around the hub of the drum in an

anticlockwise direction.

2. Take the free end and pass it between the three turns and the drum hub and then pass the free end over the three turns on the drum and under

the last turn.

3. Pass free end of the rope under the last bite and through the ‘cable’ hole in the flange. Pull firmly so that the turns on the drum lie reasonably flat.

The length protruding needs to be about 150mm.

4. Insert from inside the drum flange (centre hole) the M6 square neck cup head bolt and screw the M6 flanged serrated hexagon nut onto the bolt.

5. Wrap the rope around the M6 bolt inside the flanged serrated hexagon nut. Secure the fibre rope by tightening the nut using an M6 spanner.

When securing, ensure that the rope fibres do not catch on the bolt threads and that the rope stays inside the flanged section. Trim any excess

rope.

6. The turns around the drum will have become loose. Work the turns so that the rope lays flat against the hub and there is no slack.

Instruction for installing / replacing webbing

To install the webbing, perform the following steps bar #3.

To replace the webbing, perform all the following 7 steps.

1. gently knock out the roll pin that secures the winch drum to the shaft - a round punch or screwdriver will suffice - providing that they are smaller in

diameter than the roll pin. Light / 'firm' taps with a small hammer should remove the roll pin.

2. gently knock out the shaft to a point where it releases the webbing - be careful not to burr over the shaft corner/edge or damage the bushing

3. remove old webbing

4. ensure loop of new "Jarrett" brand webbing is flexible/loose

5. locate webbing 'loop' into slot of the winch drum and secure with shaft (which goes through the loop)

6. gently relocate shaft into bushing - a drop of general purpose oil on the bushing would not go astray

7. align pin hole on winch drum and shaft and gently tap in roll pin till it is flush

Preparing for Operation

Important !

When determining whether the boat will exceed the load rating, consider the total force required to move the boat.

Consider the operation. Do not begin until you are sure you can perform the entire operation without hazard.

Inspect all components of the system.

Inspect the winch and other equipment in accordance with Inspection instruction.

Operators should be in good health, alert and suitably clothed (i.e. no loose clothing)

The boat must be clear of objects and free to move. Ensure the boat will not tip, spin, roll away, or in any way move uncontrollably.

Know your boat and make sure you do not exceed the load rating of the winch or any other equipment in your system.

Attaching the Boat

Warning

Do not wrap the wire cable / fibre rope around the boat winch connection. This damages the wire cable / fibre rope

and could damage the boat. If necessary, use a sling or other approved device.

Clear objects from the path of the boat so you can move it freely and observe it at all times during the operation.

Attach the boat using a nylon sling, shackle or other approved rigging device.

Seat the sling / shackle in the saddle of the snap hook with the hook latch completely closed. If an S-Hook is used, the sling / shackle is positioned in the

S-hook, and the winch drum operated slowly to retrieve the slack cable / webbing / fibre rope. When the cable / webbing / fibre rope is taut, check to

ensure the sling is correctly positioned in the S-hook / snap hook prior to moving the boat.

Centre the load on the hook so the boat will remain balanced and not tip or rotate to one side.

Loading...

Loading...