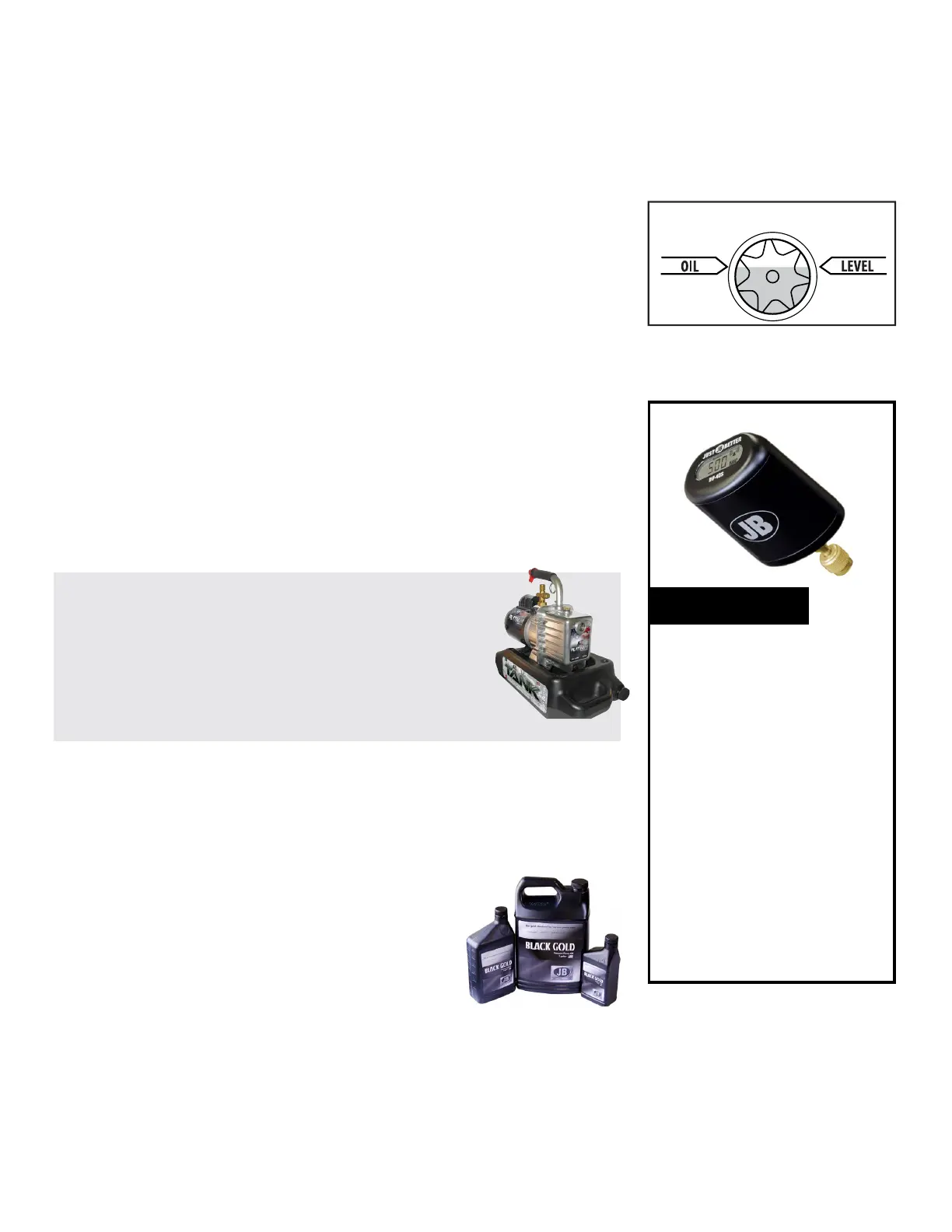

Diagram A

WIRELESS MICRON GAUGE

3

IMPORTANT: OIL LEVEL MUST BE ABOVE

HALF WAY IN SIGHT GLASS

CARING FOR YOUR PUMP

In order to make the best use of your investment, familiarize yourself with the new features and operation instructions

before starting the pump. With routine care the Platinum

®

pump will provide years of reliable service by following proper

maintenance guidelines. Platinum

®

pumps are designed for deep vacuum work in refrigeration systems and

air conditioning only.

OIL – PUMP OIL ACTS SIMULTANEOUSLY AS A COOLANT, LUBRICANT & SEALANT

IMPORTANT: Use oil specically rened for deep vacuum pumps. Using oil

not rened for deep vacuum pumps and/or operation with contaminated oil will

void warranty.

Slowly add oil until oil level rises to the top of the OIL LEVEL line (see Diagram A).

Replace oil ll plug.

If oil is too low, you will hear air out of the exhaust. If the oil level is too high, excess oil

will be blown out the exhaust. Pump oil should be changed after each use. If the system

is heavily contaminated, oil may have to be changed several times during evacuation.

After lling the pump with oil, it is best to check the oil level while the pump is running.

AFTER EVACUATION, OIL CONTAINS RUST FORMING WATER AND CORROSIVE ACIDS.

DRAIN IMMEDIATELY WHILE PUMP IS WARM.

CHANGING OIL

To reach deep vacuum, Platinum

®

pumps need clean, moisture-free oil throughout

evacuation. Care should be taken to avoid contact on skin and clothing when

changing oil. A convenient way to disposed of oil is using the DV-T1 TANK oil

caddy after every evacuation while the pump is warm and the oil is thin.

1 Place the Tank on a level surface. Unscrew black plug

counterclockwise in the drain base to open.

2 Place vacuum pump in the cradle and drain pump.

3 Once the pump has nished draining, turn the black cap

clockwise to close after every use (the Tank can hold up

to 5 oil changes).

4 Close drain on pump. Remove oil ll cap and ll to top of

OIL LEVEL line with BLACK GOLD Pump Oil. Replace oil ll cap.

FLUSHING

ALWAYS DRAIN PUMP BEFORE FLUSHING!

If the oil is badly contaminated, ushing may be necessary.

Slowly pour 1/3-1/2 cup of BLACK GOLD Pump Oil into the intake connection while

pump is running. Repeat as required until contamination is removed from oil reservoir,

pump rotors, vanes and housing.

Dispose of all oil used in ushing of pump.

IMPORTANT

DO NOT START PUMP BEFORE ADDING OIL

OPERATION

The following procedures will prevent oil from being drawn into the pump cartridge and creating hard start-up.

START-UP:

Open one intake port and isolation valve, close gas ballast

valve and start pump. Make vacuum connections.

Crack gas ballast valve for the rst part of the evacuation

procedure. After pump quiets down from initial volume of air,

close valve and continue evacuating. Failure to close valve

will result in poor pump performance.

• Accurately measures vacuum from

12,000 microns down to 10 microns

• Heavy duty water resistant

• Includes backup display on the gauge

• Programmable with low & high limit alarm

• Smart phone control through the new,

free JB App

• Remote management capability

• Wireless Bluetooth

®

• Data logging capabilities for sharing job

analytics

• Rechargeable battery

• Factory calibrated

• Measures in microns, psia, inhg, Pascals,

torr, mtorr, and mbar

• USB charging adapter for wall or computer

charging

• Light or dark app theme for visibility in

different environments

DV-40S

SHUT-DOWN:

Close isolation valve and open gas ballast valve all

the way. Continue running pump for 2-3 seconds. With

gas ballast valve still opened, stop pump and then

close valve.

Remove hose connections and cap intakes.

Loading...

Loading...