RS T4F Diesel Generator

|

G400RS 25

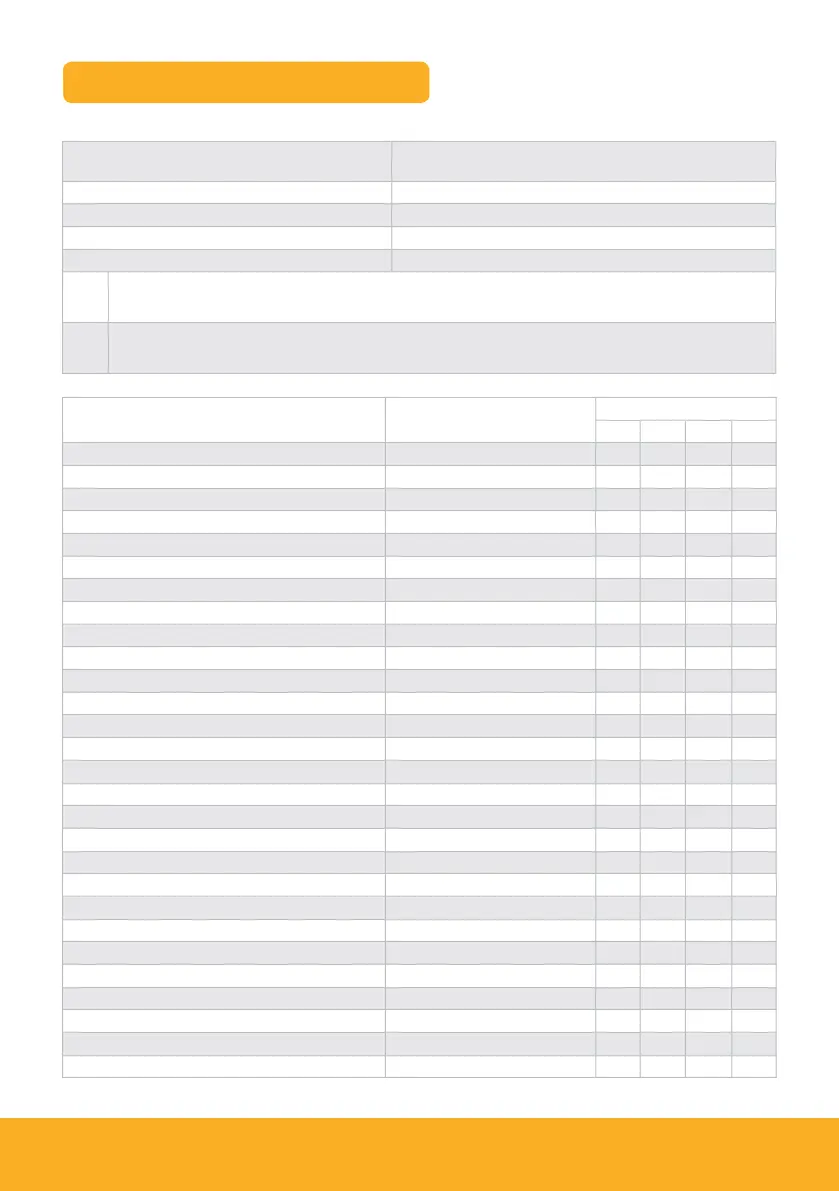

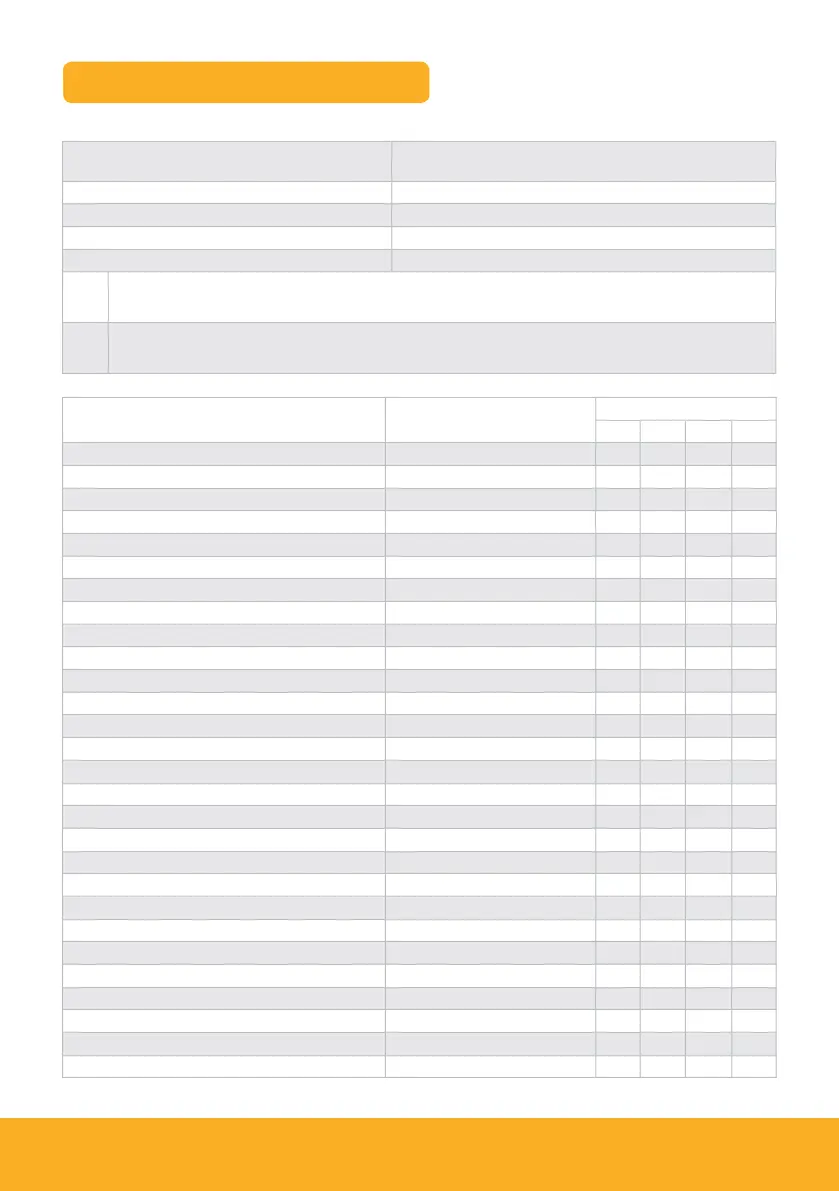

Maintenance schedule

Operation

Interval (Hours)

10 50 500 1000

Visual inspection Overall visual check

O O

o o

Control panel Check operation

O O

o o

Safety decals Check condition

O

o o

Emergency stop switches Check operation

O

o o

Earth leakage RCD & MCB Check operation

O

o o

External power socket box Check condition

O

o o

Battery terminals and voltage Check

o o

Control panel events history Check

o o

Bus bar cover safety switch Check operation

o o

Alternator and engine mounting bolts Check tightness

o o

Bus bar terminals Check tightness

o o

Machine earth connection Check condition

o o

Engine and controller harness Check condition & connection

o o

Coolant quality and level Check

O O

o o

Oil level Check

O O

o o

Water separator & fuel filter Drain

O

o o

Oil & filter Change

o o

DEF filter Change

o

Air cleaner outer element Change

o

Water separator & fuel filter Change

o o

Engine fuel filter Change

o o

Front End Accessory Drive (FEAD) belt condition Check

o o

Engine mounting bolts for tightness Check

o o

All Hoses – Condition Check

o o

Radiator Check

o o

Battery terminals and voltage Check

o o

Generator alternator cables Check condition

o o

Generator alternator terminals Check tightness

o o

Interval (h) Calendar equivalent

10 Daily

50 Weekly

500 Six months

1000 Yearly

O

Service task can be completed by a competent operator. Details of how to complete the task are given

in the operators manual.

o

We recommend that a service engineer completes the service task. Details of how to complete the

service task are given in the service manual.

Loading...

Loading...