Section 1 - General Information

Torque Settings

Hydraulic Connections

1-36 1-36

1-05-01 Issue 02

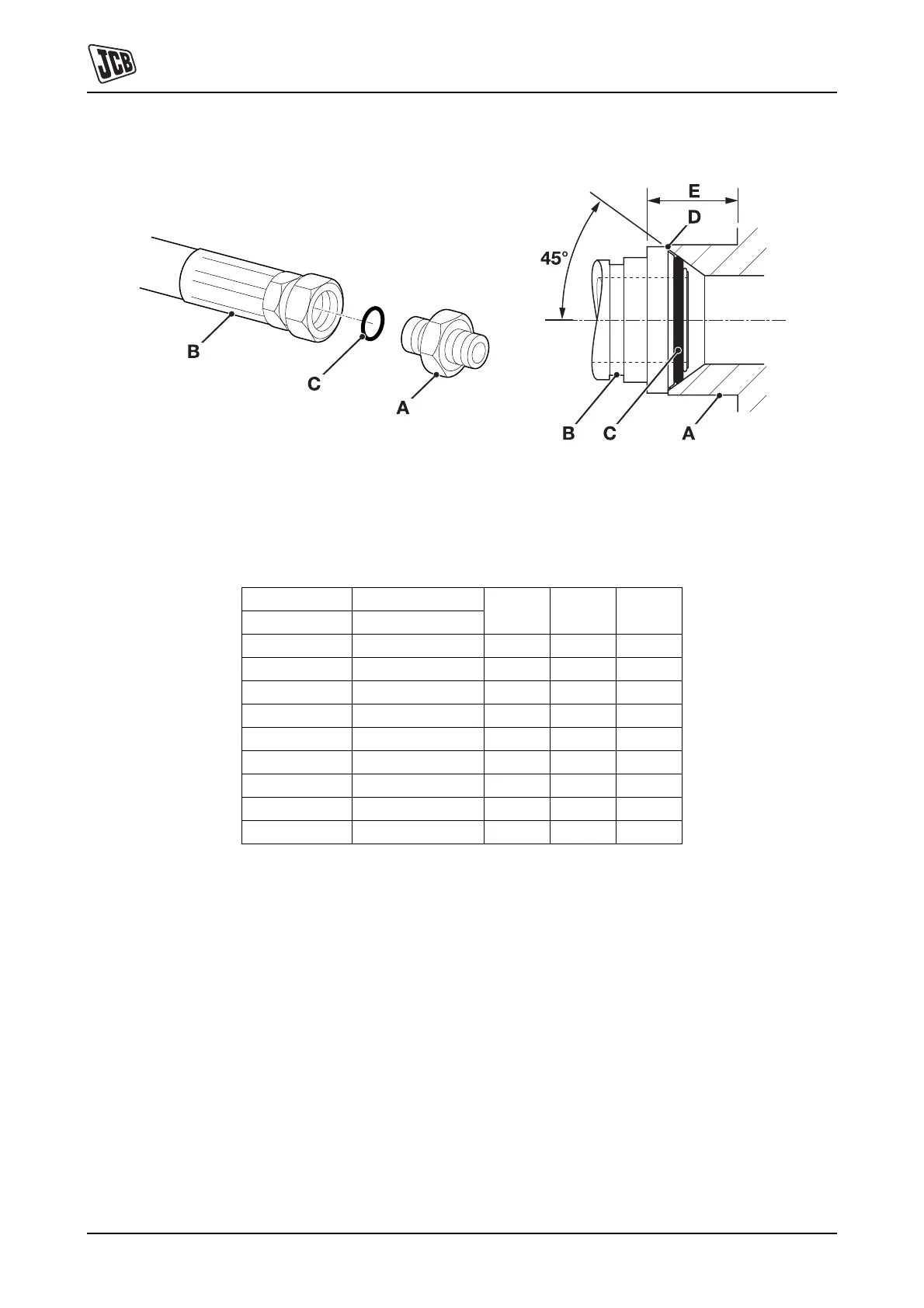

'Torque Stop' Hose System

Fig 6.

`Torque Stop' Hoses 6-B screwed into adaptors 6-A seal

onto an 'O' ring 6-C which is compressed into a 45° seat

machined in the face of the adaptor port. To prevent the 'O'

ring being damages as a result of over tightening, 'Torque

Stop' Hoses have an additional shoulder 6-D, which acts

as a physical stop.

Note: Minimum dimension 6-E fixed by shoulder 6-D.

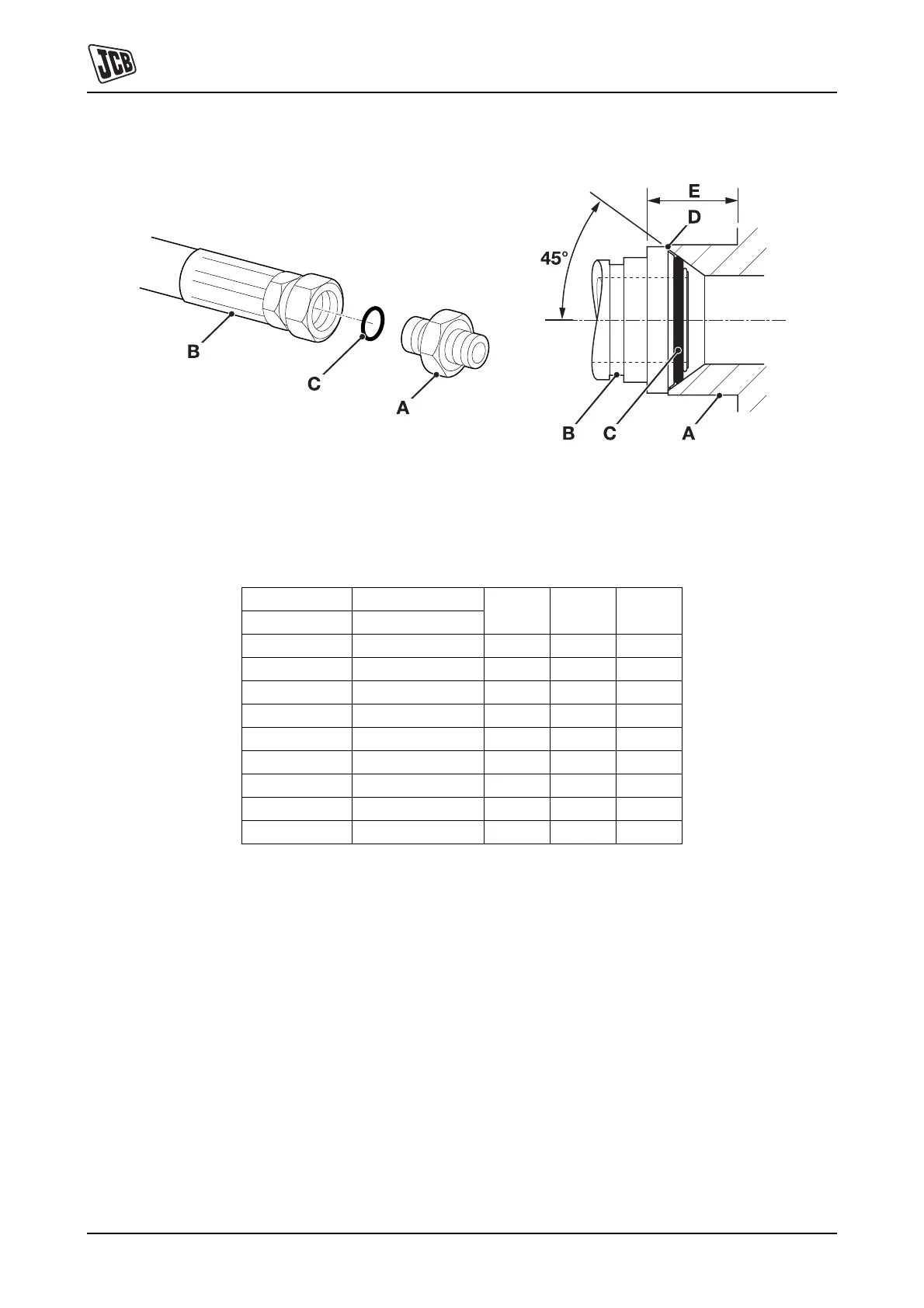

Table 13. BSP `Torque Stop' Hose - Torque Settings

BSP Hose Size Hexagon (A/F)

Nm kgf m lbf ftin. mm

1/8 14.0 14.0 1.4 10.0

1/4 19.0 27.0 2.7 20.0

3/8 22.0 40.0 4.1 30.0

1/2 27.0 55.0 5.6 40.0

5/8 30.0 65.0 6.6 48.0

3/4 32.0 95.0 9.7 70.0

1 38.0 120.0 12.2 89.0

1 1/4 50.0 189.0 19.3 140.0

1 1/2 55.0 244.0 24.9 180.0

Loading...

Loading...