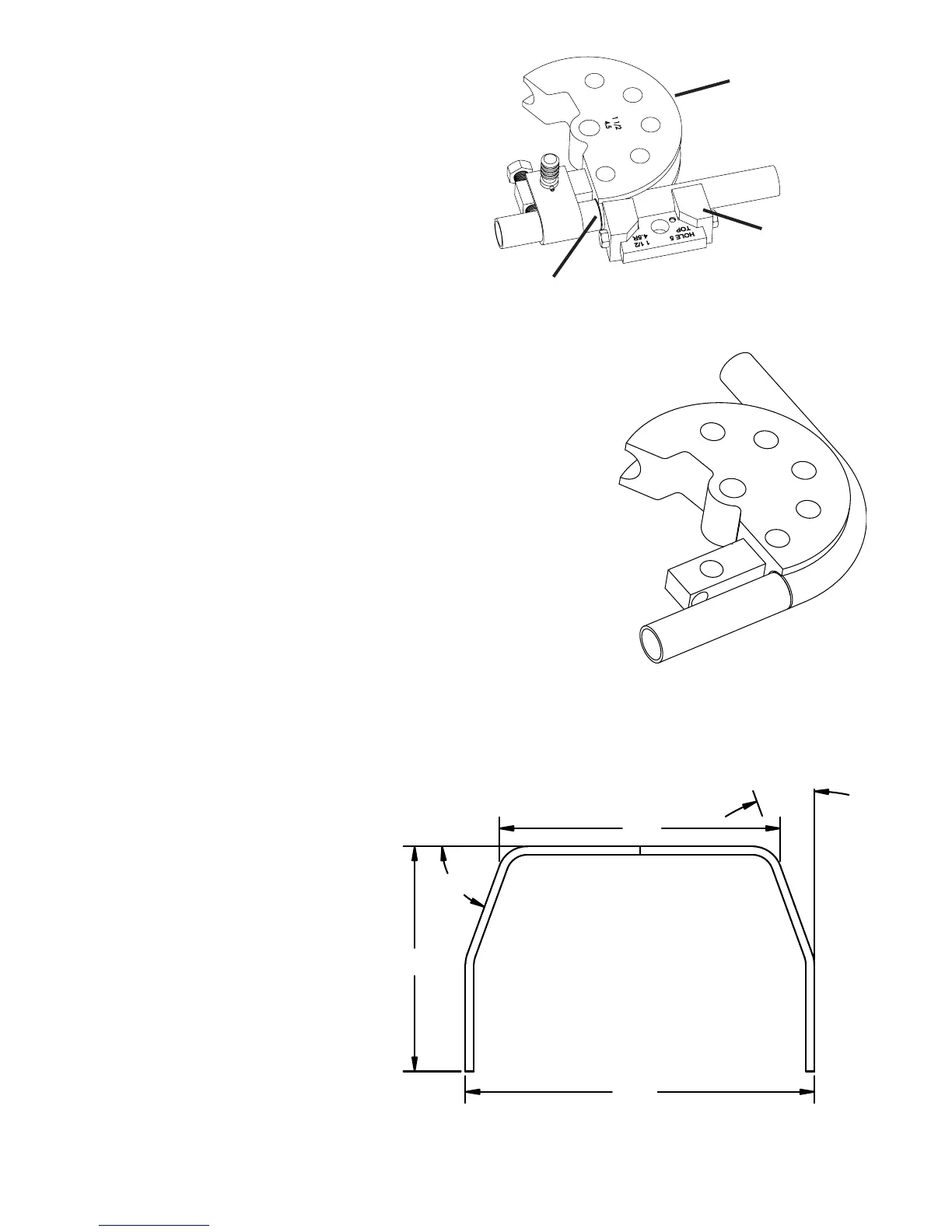

Load this tube into your bender as shown in

Figure18.Notethatonlythediesetandtubing

arevisibleinthegure.Theactualbenderand

thedieset’su-straparenotshownsothatyou

can see what we’re trying to achieve. Place the

scribedlineattheatedgeoftheformingdie.

Neveruse thefollowbarasareference.Ifthe

formingdiehasalockboltonit,useittosecurely

tighten the tubing in place. It’s very im por tant that

thismark stays inline withthedie’satedge

during the bending process or tem plate will not

give you accurate results later.

Figure 18 - Tube po si tioned

in forming die

Template Line

Followbar

Forming Die

Figure 19

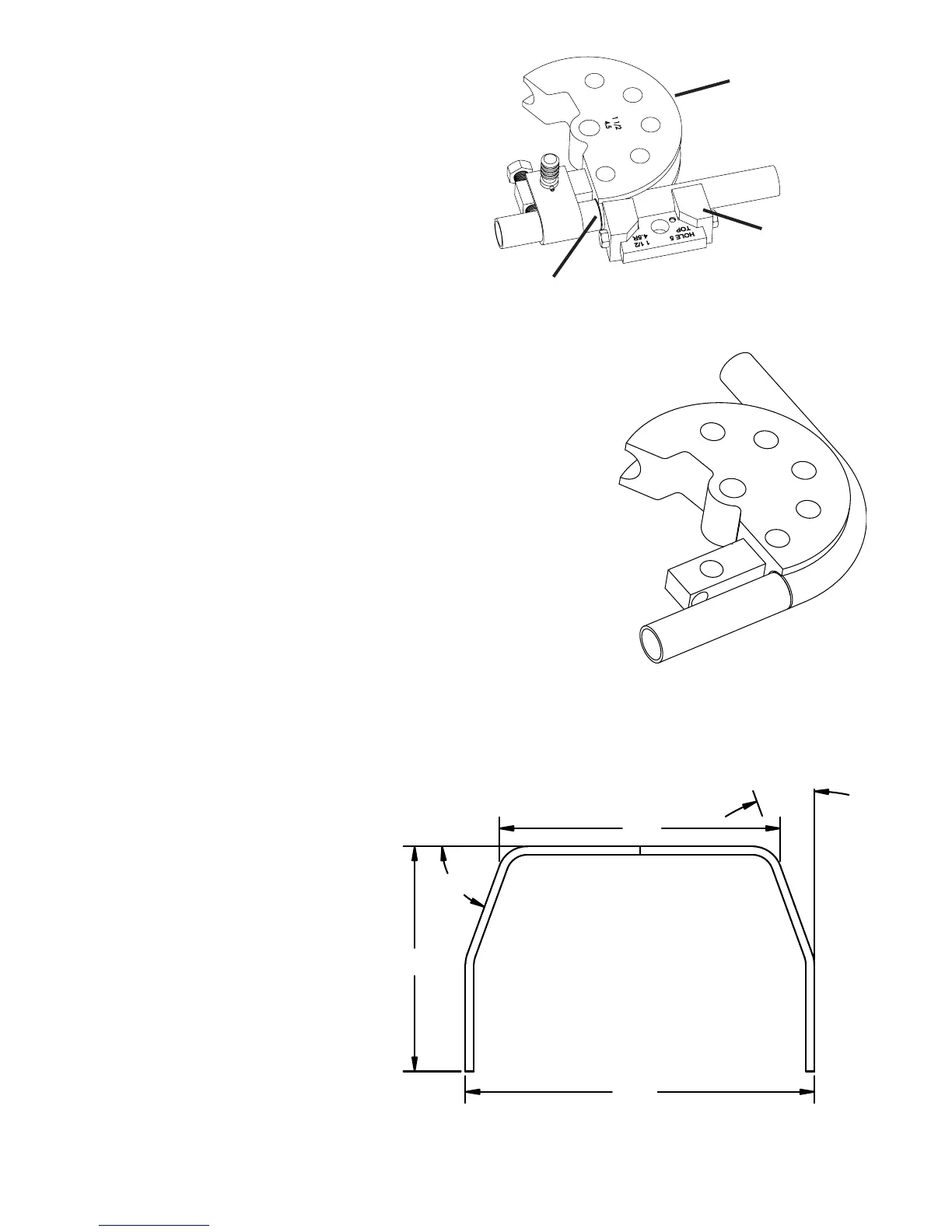

AsshowninFigure20,therollbarwillbe40”tallfromtheoortoitsUPPERside.Itwillbe62”wide

outsidetooutside.Thetoptwobendsare70

o

eachandthetwolowerbendsare20

o

each. I recommend

that you purchase an adjustable carpenter's protractor to help determine the degree of bend for your

specicjob.Theyaremadeofclearplasticandhavelegsapproximately12”long.

To de ter mine the total length of

tubing needed, you could sit down

and calculate it. This is described in

thenextsection"BendingMethod#2"

which presents a more mathematical

method to bendtubing. However, for

thisapplication,Ithinkit’sawasteof

time.Timeusuallycostmorethantubing,

sohere’sthefastway:Takethetotal

widthoftherollbar(62”)andadditto

twicetheheight(40”)whichgivesusa

lengthof142”(62”+40”+40”).Thisis

slightlytoolong,maybeafootareso,

butthere’sapopularruleinfabricating:

It is easier to remove material then to

addit.Throughexperienceyouwilllearn

howmuchextratubingyoumustleave

to complete the part.

Bendthetubetoanishedbendofexactly90degrees.Onthis

example,Ihadtobendto94degreestoachieveatrue90degree

bendafterthetubingrelaxed.Cutthestraightlengthoftubingthat

isnotscribedto6”longsothatitmatchesthescribedside.Thisis

not really necessary but it does look nice. Debur both ends and then

paintthetemplateaneasilyvisiblecolor.Whydoesitneedpaint?

It doesn’t. But after losing this thing a few times you’ll get the idea.

Thetemplateisnished.

If you work with different types of tubing that are of the same

sizebutdifferintheamountofspringbacktheyproduce,possibly

becauseofadifferentmaterialorwallthickness,youmayneedto

make a separate template for each one. You can decide later if this

necessary depending on the accuracy that you require.

Figure19showsanishedtemplatebendstillinthedie.Note

the position of the scribed line on the tube.

Figure 20

Time To Start Bending...

- 9 -

Loading...

Loading...