Animportantruleofbendingisto,ifpossible,alwaysmakethebendsclosesttothecenterrstand

workyourwayout.Thisallowsyoutomakemeasurementcorrectionsbetweenbends.Basedonthisrule,

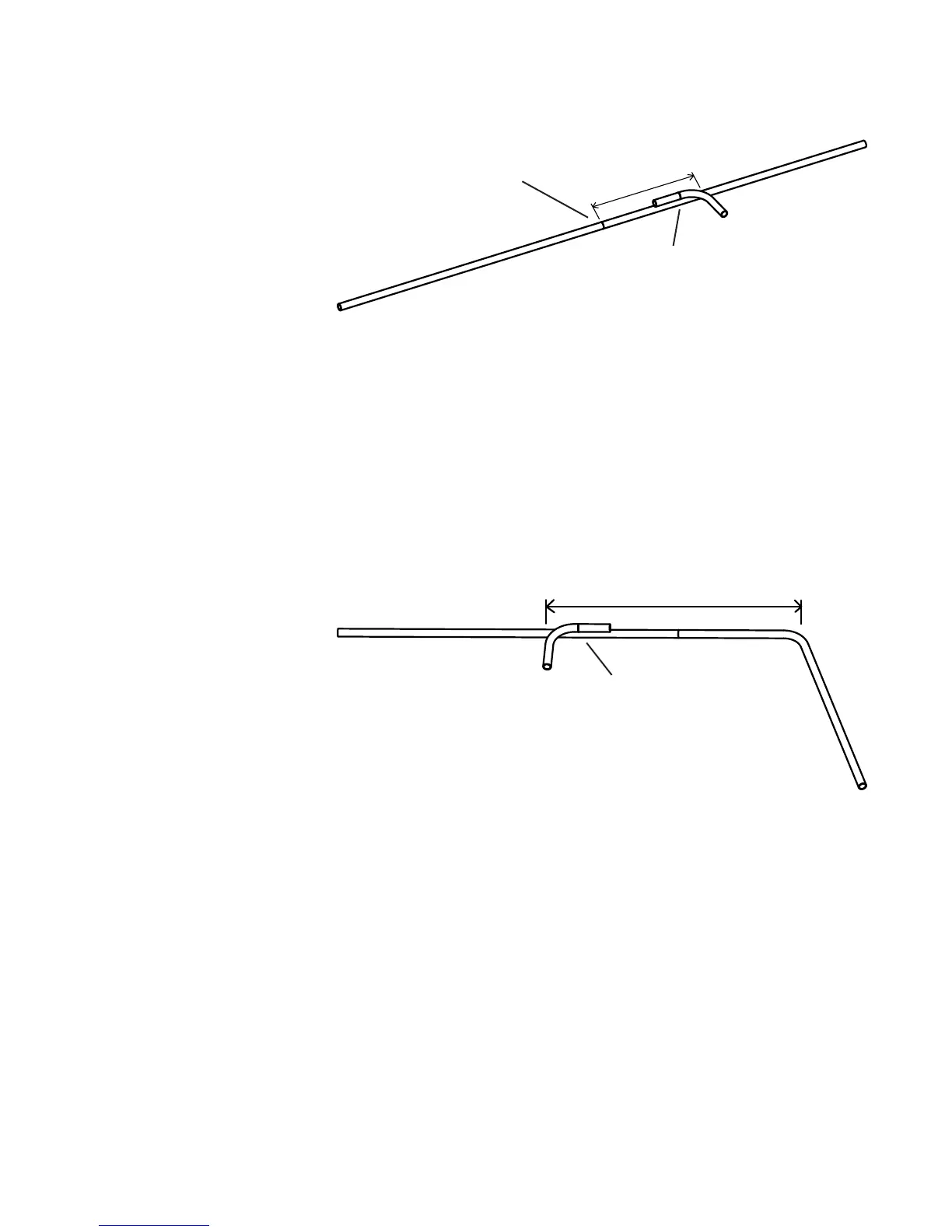

place a mark at the center of the rollbar tube. This is shown Figure 21.

BEND 1:

The rst bend will be the

upper right side bend. Referring

toFigure20,theupperdimension

of the rollbar is 50”. From the

center of the rollbar to the outside

ofthebendis25”(50”dividedby

2). Lay the tubing to be bent on

theoorandholdthetemplate

with the scribed side parallel

totherollbartubinganddirectlyaboveit,asshowninFigure21.Thescribedsideofthetemplatewill

alwaysfacetowardsthecenterofthetubingbeingbent.Usingatapemeasure,slidethetemplateleftor

rightuntilitis25”fromitsoutsideedge,shownbytherightarrowinFigure21,totherollbar’scentermark.

Usingamarker,drawasmalllineontherollbardirectlybelowthescribedline.Takenoteofwhatside

of this mark the bend needs to be and draw an ‘X’ there so that when you load the tube into the bender

you’llbebendingonthecorrectside.Sincethedesiredbendisonly70

o

andthetemplateis90

o

,you

willhavetouseyourbestjudgementofwhenthetemplateis25”out.Thisgetseasierwithexperience.

Now,loadthetubeintothebenderandmaketherstbend.Don’tforgettooverbendalittletoaccount

fortubespringback.Forthismaterial3to4degreesshouldbesufcient.SinceallJDSquaredbenders

are equipped with degree of bend indicators this is easily accomplished. Once you know the correct over

bendrequired,youmaywanttorecorditforfuturereference.

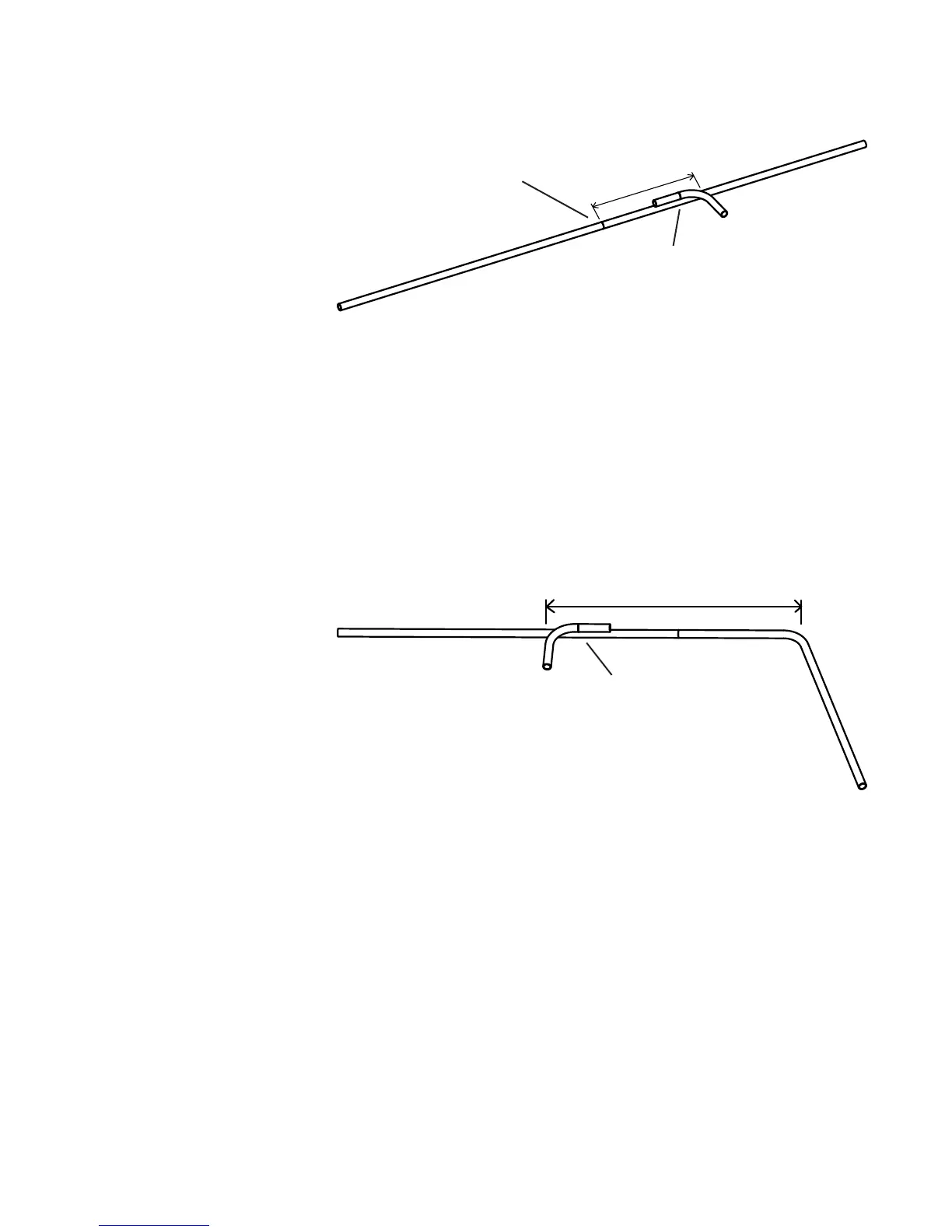

BEND 2:

Place the template above

the rollbar tube with the template

line facing bend 1 as shown in

gure22.Usingatapemeasure,

position it for the desired 50”

outside to outside of the two

top rollbar bends. DO NOT

use the tube’s center mark

as a reference and place the

template 25” left of center. The

reasonforthisisthatiftherst

bendwasnotmadeattheexactrightspottoachieve25”fromcenteryoucancorrectfortheerrorinthe

secondbend’sposition.Onceagain,sincethebendwillbe70

o

andthetemplateis90

o

you must use your

judgementastowheretopositionthetemplate.Placeamarkontherollbartubeexactlyunderneaththe

template line. Load the tube in the bender so that the bend will be made on the CORRECT side of the

tubeandmakethe70

o

bend.

Erasethecentermarkontherollbartube.Usingthetapemeasure,placeanewcentermarkexactly

midwaybetweentheoutsideofthetwobends.Why?Let’ssayyourmeasurementshowsthetwotop

bendsarereally501/4”wideinsteadofthedesired50”.Inthatcase,youroldcentermarkcouldbeoffby

asmuchasa1/4”.TheNEWcentermarkcorrectsthiserror.That’sthecoolpartabouttemplatebending.

Yourerrorscangenerallybexedwiththenextbend.Alsonotethatifyouhadnotstartedyourbending

from the center of the rollbar you would not have been able to make the correction. Every bend adds a

littlemoreerrorandyouendupwitharollbarthatdoesnott.

Figure 21 - Template positioned for 1st bend.

Figure 22 - 2nd bend position

Tube’s

Center Mark

Template Line

Template Line

- 10 -

Loading...

Loading...