- 8 -

First,youneedtomakeatemplate.Forourexample,

wearegoingtouse11/2”o.d.x.120”wallweldedseam

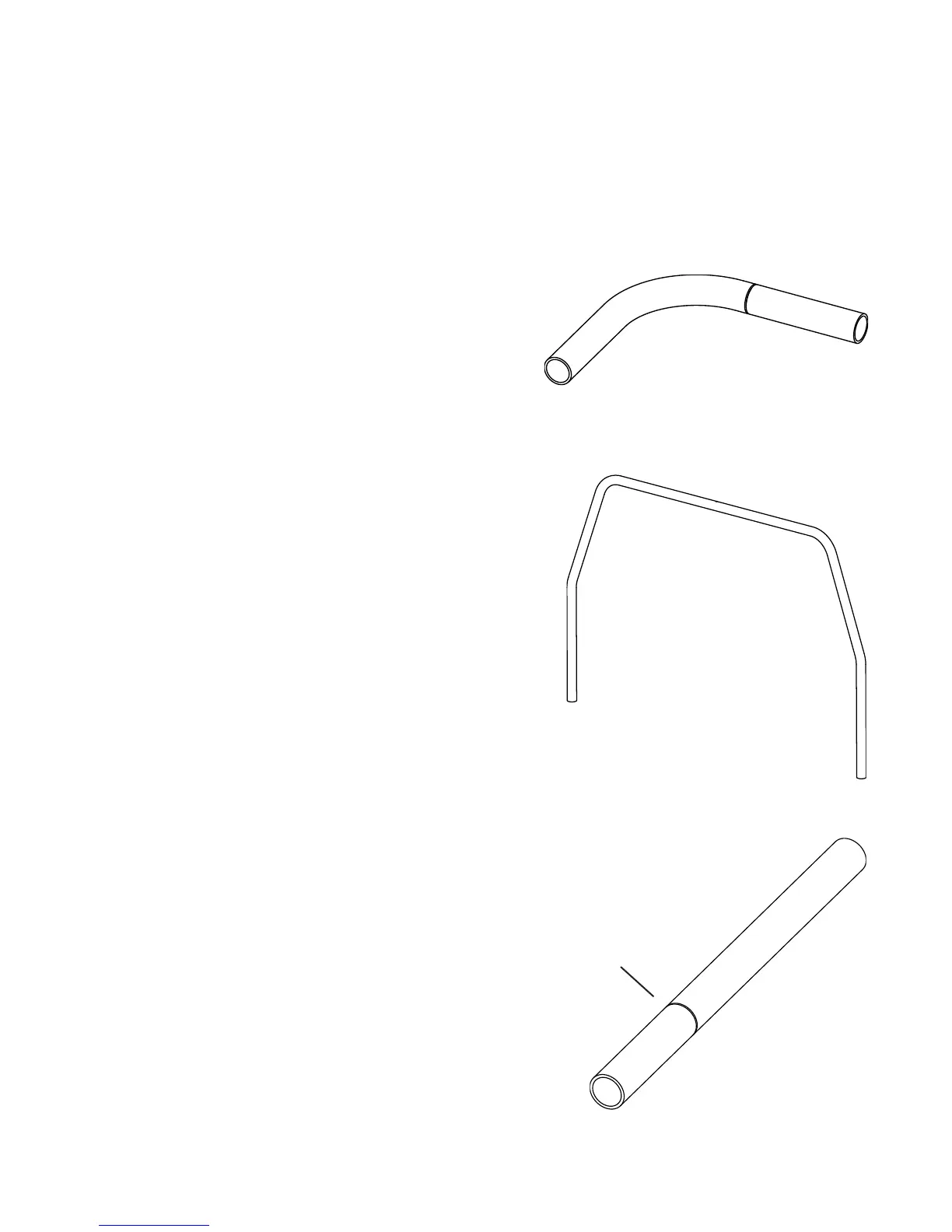

mildsteeltubing.AsshowninFigure15,thetemplateisa

pieceoftubingbentto90degreeswithapproximately6”

of straight tubing on each side of the bend. Cut a piece of

tubingroughly30”long.Next,scribeanaccuratelineall

thewayaroundthistubing6”fromtheend.Anaccurate

and easy way to do this is to use an inexpensive pipe

cutter. Your local home supply store should carry them in

the plumbing de partment. A small lathe with a sharp cutter

alsodoesagoodjob.Scribethelinedeepenough,roughly

.015”,sothatwhenyoupaintthetemplate,thelineisstill

clearlyvisible.Handscribingthislineisdifcultandnotrec-

ommended. The tube should now resemble Figure 17.

Learning the operation of a bender is fairly easy. The real challenge is accurately placing the tubing

intothebendersothatthebendcomesoutintherightposition.Thisshorttutorialexplainsthesimple

process of template bending.

Make a sample bend called the Template as shown in Figure 15. A permanent mark scribed on the

template allows you to measure and visualize where the bend should be placed in the tubing. Once bent

the tubing will spring out to a larger radius than the forming

die’s size in di cates. The larger the O.D. or the stronger

the tubing, the greater the springback. For instance,

chromemoly tubing will springback roughly twice as far

astheexactsamesizeandwallthicknessofweldedseam

mild steel tubing. By using a tem plate bend with the same

kindoftubingyouaregoingtobend,youdonothaveto

worry about this springback be cause the template has

alreadysprungouttoitsnishedsize.

You may ask if buying bending software is a good

idea.Ibelievebendingsoftwarecanonlyjustiedfortwo

reasons:Creatingpartdrawingsifthesoftwaresupportsthat

functionandforsettingupafullyautomaticCNCbender

for the initial test of a part with multiple bends. Even using

the software the bend locations usually need to be hand

tweaked for accu racy before going into production. Most

pro fessional fabricators use a method similar to what is

describedhere. Itisextremelyeasy,accurateandfast.

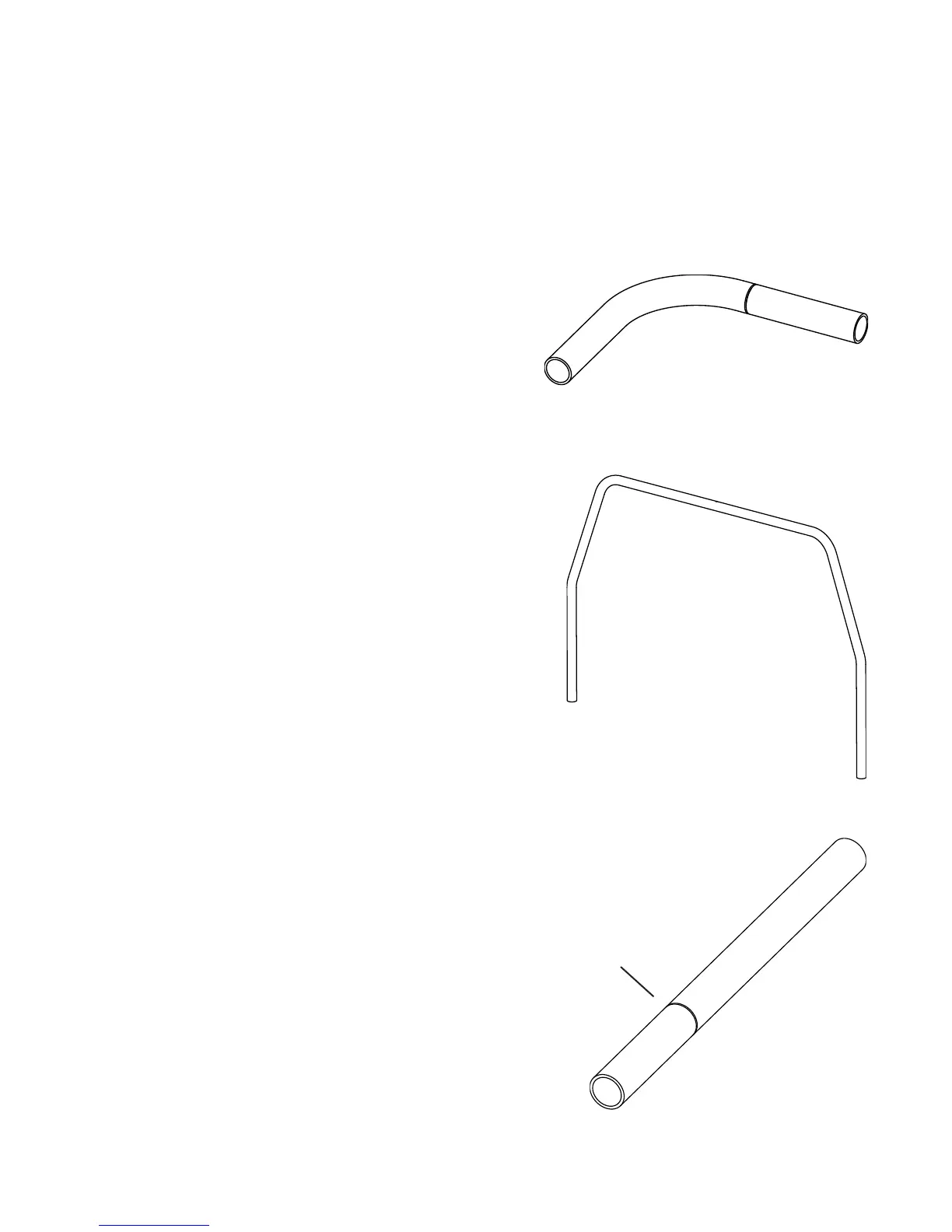

However,whatifyouneedtobend500pieces.Howwould

youusethisprocess?Don’tworry,it’sasimpletechnique

thatIwillexplainlaterbutrstlet’sjustcompleteasingle

piece job. To do this I’m going to go through the whole

process that I use to make a four bend rollbar for a racecar

asshowninFigure16.Thisisagreatexamplebecauseit’s

acommonrequest,therearenosimple90degreebends,

anditisgenerallyaone-offpiece.Soholdontoyourlug

nuts,herewego.

Bending Method #1 - Using Template Bends

The Easy Way To Position Bends

Figure 15 - Sample Template Bend

Let’s Make A Bend Template...

Figure 16

Sample Rollbar

Figure 17

Template Line

Loading...

Loading...