Die Set Installation and Bending Procedure

There are two types of forming dies provided for the Model 3 Bender. Those with drive holes and those without. The drive holes

aretheve1"holesdrilledinacircularpatternaroundtheformingdie'scenterhole.A7/8"diameterpininsertsthroughthedrive

links and through the forming die's drive holes when in operation. The drive holes are drilled 1/8" oversize to provide easier pin

installation.Toprepareforbending,followthestepsbelowdependingonthetypeofdieset.

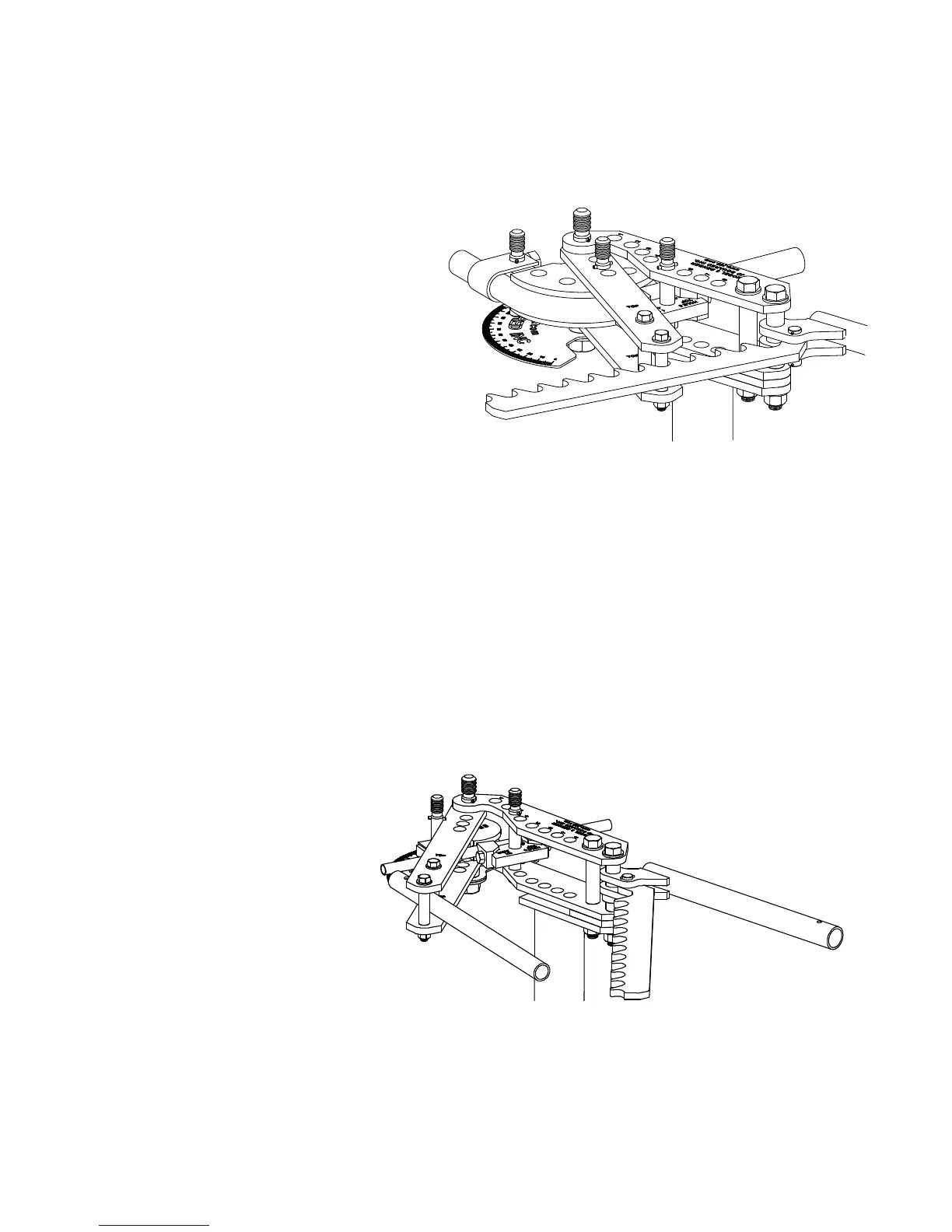

WITH DRIVE HOLES:

Place the forming die into the bender using the 1"

framepin.Ifbendingsquaretubing,thoroughlylubricate

theformingdie'sgroove.However,ifbendingroundtubing

orpipe,NEVERlubricatetheformingdie'sgroove.Ifyou

do,thetubewilltendtoslipbackwardsinthediewhile

bending,whichinturncausesthetubingtokinkorwrinkle.

PlacethetubeintotheformingDie.InstalltheU-Strap

withtheshorter7/8"U-strappin.Ifnecessary,tightenthe

U-strapbolttopreventthetubefromslippingthroughthe

die will bending. It's a good idea to cut a slice out of a

bigger piece of tubing place it between the bolt and tubing

to prevent the bolt from dimpling the tubing. If bending

thinwalltubing(.065"orthinner)youmustalwaysuse

theU-strapbolt.

Next,usingthe7/8"FollowbarPin,placetheFollowbar

into the bender. See page 5 for the correct way to install

the Followbar. Lightly spray some lubricant on the outside

of the tubing so that the tubing will slide through the Followbar easily. Any spray lubricant works well. If you are bending tubing

withawallthicknessof.065"orthinneryoumaywanttoskipthelubeentirely.Thiswillhelpthefollowbarsticktothetubingduring

ratchet repositioning and generally helps prevent wrinkling. Make sure all pins are completely seated in their holes. Failure

to do this may cause damage to the bender links or worse yet the operator may slip and fall.

RotatetheRatchetLeverfullycounter-clockwise.EngagetheRatchetontotheouter3/4"drivelinkspacertube.Lightlypull

onthehandletopreloadthetubing.Donotpullhardenoughtoactuallybendthetubing.Usingafreehand,loosenthedegree

platenut.Rotatethedegreeplateuntilthedie'spointerisat0degreesandthenhandtightenthenuttosecureitintoposition.

Nowyou'rereadytobend.PullonthehandleinaclockwisedirectionuntiltheRatchetLevercannotrotateanyfurther.Returnthe

Ratchet Lever to the starting position. Initially release the Ratchet easily so as not to move the tubing and minimize spring back.

Reengagetheratchetandpullagain.WhenthelastRatchettoothisreached,returntheRatchetLevertoitsstartingposition.

Removethe7/8"DrivePinandrotatetheDriveLinkscounter-clockwiseuntiltheDrivePinmaybereinstalledthroughanother

holeintheBendingDie.Becarefulnottomovethetube.Nowrepeattheabovebendingsequenceuntilthedesireddegreeof

bendisobtained.Toreleasethetubingfromthebender,removethehandlefromtheRatchetLever.Insertitdiagonallythrough

the3/4"drivelinkspacertubesandpullcounter-clockwise.TheFollowbarwillreleaseitsgripandthetubingmayberemoved.

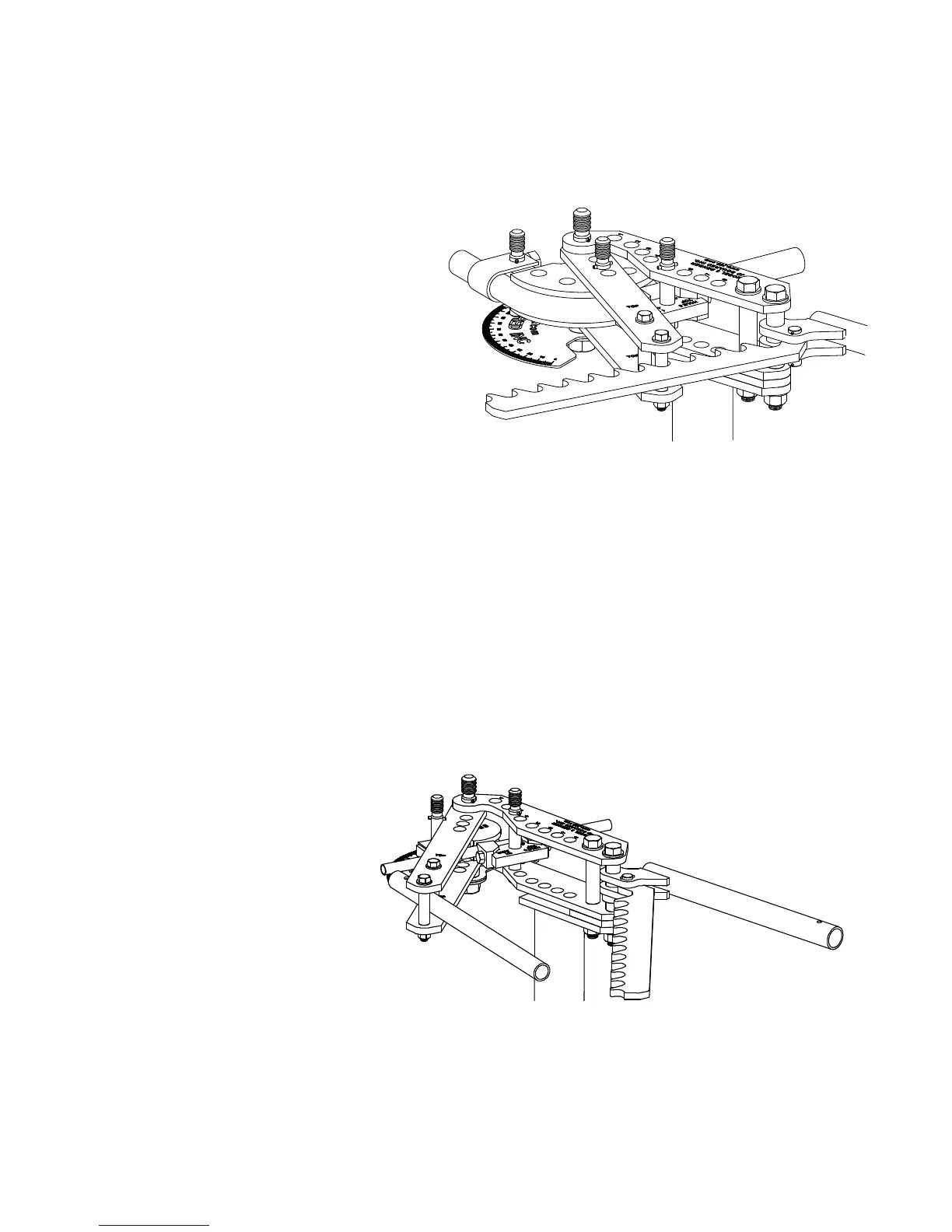

WITHOUT DRIVE HOLES:

These dies typically have a center line

radius of less than 3". Because the radius of

thedieissosmall,driveholescannotbedrilled

into the die. This does not present a problem

as the tube sizes for these dies is of relatively

small diameter and is easily bent. The ratchet

is not used.

Die installation procedure:

Swing the ratchet assembly out of the

way as shown below. Place the forming die

into the bender. Place the tubing to be bent

in the bender and using the 5 1/4" long drive

pin(nottheshorterU-Strappinthatisusually

used)installtheU-strap.Ifdesired,tightenthe

U-strapbolt tosecure thetubing tothe die.

This is not mandatory and may be omitted if

the tubing shows no signs of slipping through

thediewhilebending.Nowinstallthefollowbarbeingsuretheword'TOP'isfacingup.Rotatethedrivelinksuntiltheirfrontedge

pushesdirectlyontheU-strappinasshowningure6.Placethehandlediagonallythroughthedrivelinks'two3/4"spacertubes.

Lightlypullonthehandletopreloadthetubing.Donotpullhardenoughtoactuallybendthetubing.Usingafreehand,loosen

thedegreeplatenut.Rotatethedegreeplateuntilthedie'spointerisat0degreesandthenhandtightenthenuttosecureitinto

position.Now,simplypullthehandleandobservethepointeruntilthedesireddegreeisreached.

- 7 -

Figure 14 - Handle installed and ready to bend without drive holes

Figure 13 - Bending with drive holes and ratchet

Loading...

Loading...