TherstthingyouneedtodoistodeterminetheactualstartinglocationofabendproducedbytheBendingDieyouinstalled

inthebender.Thiscanvarybetweendiesetsandmustbecheckedforeverydiesetpurchased.Inthebelowexampleweare

using11/2"O.D.tubingandaBendingDiewithaCenterLineRadiusof61/2".

Here'stheprocedure:

A) Placeapieceoftubing(app.21/2'long)intothebendersothatexactly12"extendsoutfromtheedgeofthedietothe

end of the tubing when the tubing is fully seated in the Bending Die's groove. Place a little bending pressure on the tube

soastoseatthetubingintheBendingDie.Notenoughtostartbendingthetubingjustenoughtoseatitinthegroove.

NOTE: If you lay a small length of tubing in the groove of a Bending Die you will notice the tubing does not seat to the

bottom of the groove. The Bending Dies are deliberately machined this way so that during the bending operation a

side force is developed in the tubing. This helps to reduce at spotting and

wrinkles.

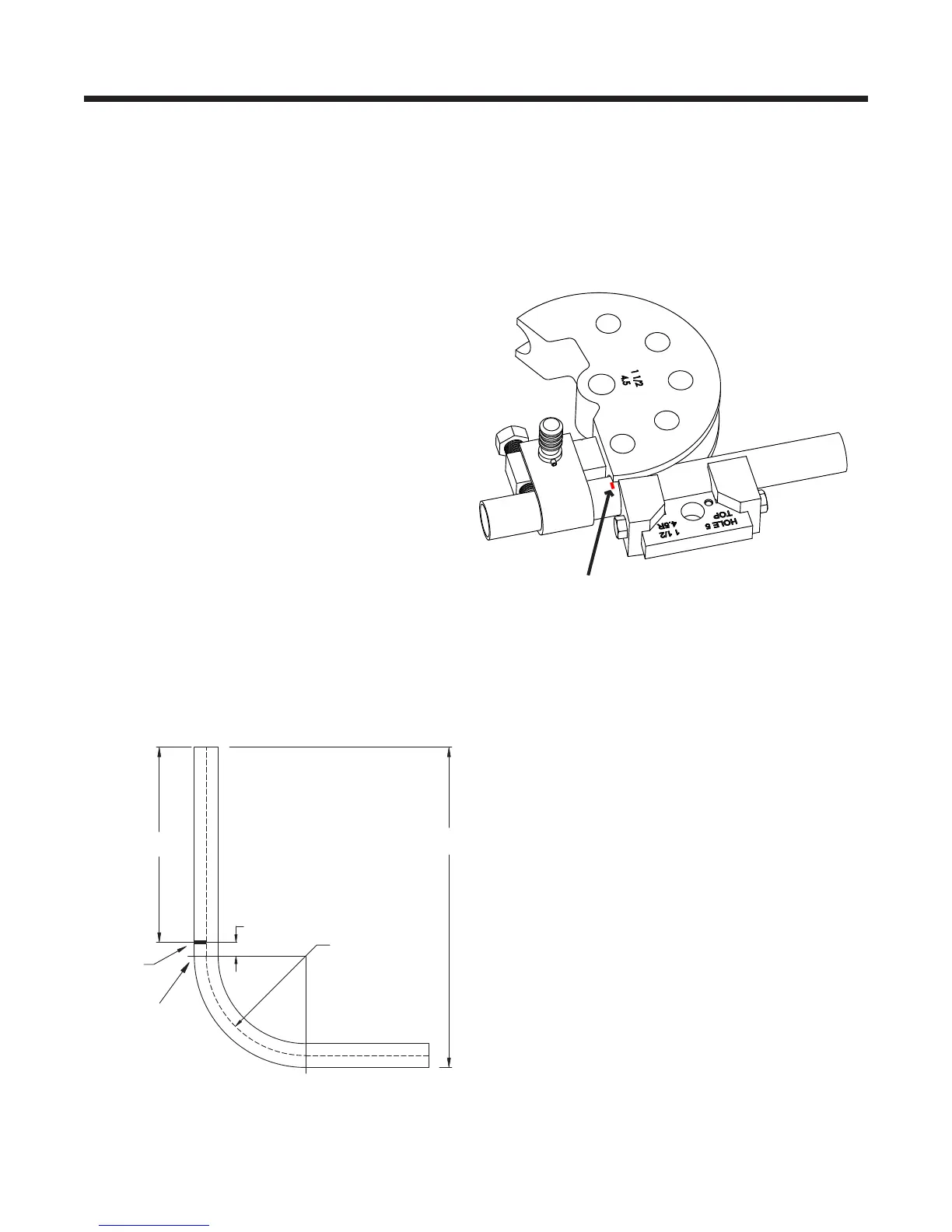

B) Using a Black Magic Marker mark a line on the

tubingpreciselyattheedgeofthedie.Seegure

25.

C) Bend the tube to an exact 90 degrees. Use a

carpenters square to check the angle. You will

have to overbend the tube a little to account for

springback.Howmuchtooverbendwillcomewith

practice. If you overbend the tube a little don't worry.

Becausecoldworkedsteelhasmemory,youcan

place the tube in a vise or anything else that will

retainit,andsimplyunbendit.Obviouslythisonly

works for small amounts of overbend. If the tubing

isunderbent,itwillbenecessarytoputitbackinto

the bender.

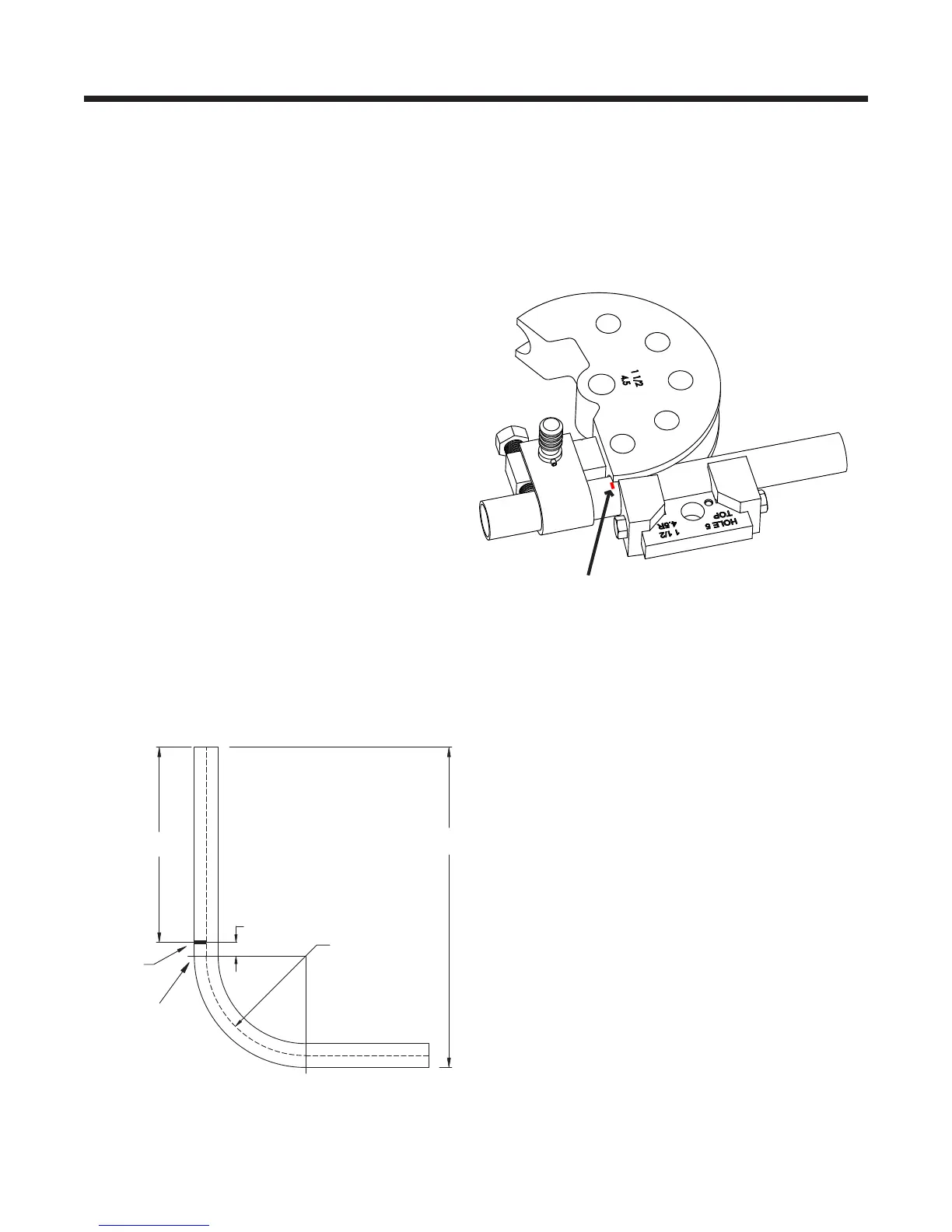

D) Withthetubebentcorrectlyto90degreeslocate

theactualstartofthebend.Todothis,measure

fromtheendofthetubetothefarendofthe90

degreebend.Intheexampleingure26thiscame

outat201/4". Subtract 61/2"forthe centerline

radius(CLR)oftheBendingDie,another3/4"for

theradiusofthetubingnotseatedinthedie,and1/8"forspringback.(SubstitutetheCLRandtuberadiustomatchyour

dieset).The1/8"gureforspringbackisanapproximation,notanexactgure.Howeveritisusuallyveryclosetothe

realthingandmaybeusedwithoutworrytodeterminetheactualstartinglocationofthebend.So:

20 1/4" - 6 1/2" - 3/4" - 1/8" = 12 7/8"

Nowsubtractfromthe127/8"theoriginal12"wehad

markedearlierandyoundthatthebendwillactually

start7/8"infromtheedgeofthebendingdie.Nowwe

knowforexample,ifwewant40"fromtheendofthe

tubingtothestartofthebend,wemustsubtract7/8"

from40"andsetthetubing391/8"fromtheedgeof

the Bending Die.

Anotherexample,youwant36"fromthebottomtothe

top of a rollbar. Tube size is 1 3/4" and you have an

actual bend start 1/2" inside of the Bending Die's edge.

TheCLRoftheBendingDieis71/2".So:36"-1/2"

(ActualBendstart)-71/2"(CLRofdie)-7/8"(Half

ofthetubingdiameter)-1/8"(Springback)=27".Set

the tube 27" from the edge of the Bending Die and

make the bend.

Bending Method #2 - Using Math Formulas

Figure 25

Actual start

of bend

6 1/2" CLR

7/8"

20 1/4"

12"

Mark

Figure 26

Mark here at the saw cut edge of

die (not at the followbar's insert)

- 12 -

Loading...

Loading...