Chapter

9

Brakes

9

-

15

LINES

TO

WHEEL

BRAKE

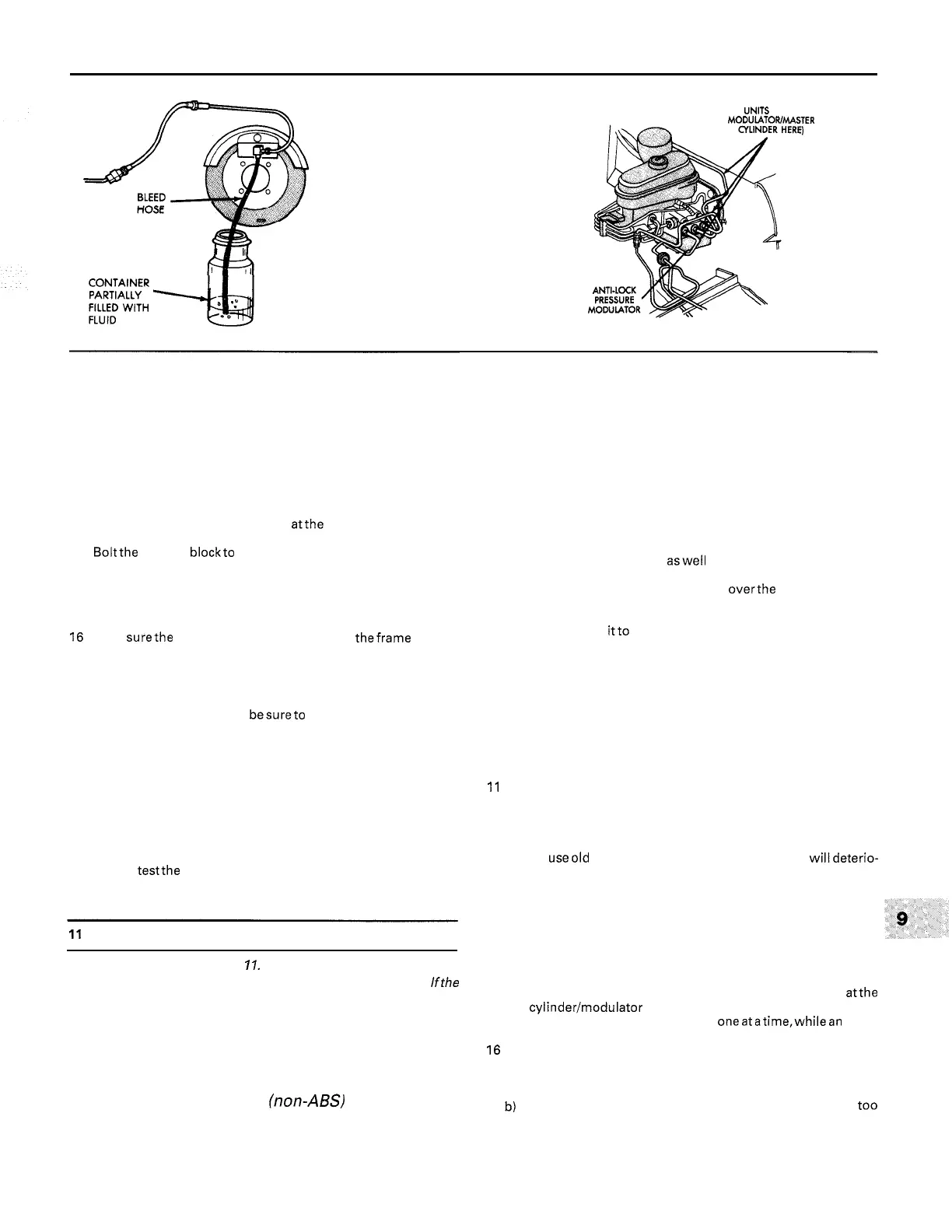

11.8 When bleeding the

UNITS

(BLEED

MODULATOWMASTER

brakes, a hose is connected

to the bleeder valve at the

caliper or wheel cylinder

and then submerged in

brake fluid. Air will be seen

as bubbles in the tube and

container. All air must be

expelled before moving to

the next wheel.

FLUID

11.15 Master cylinderlmodulator bleeding points

9 When the brake hose installation iscomplete, thereshould be no

kinks in the hose. Make sure the hose doesn't contact any part of the

suspension. Check this by turning the wheels to the extreme left and

right positions. If the hose makes contact, remove it and correct the

installation as necessary. Bleed the system (Section 11).

Rear brake hose

10 Using a back

-

up wrench, disconnect the hose at the frame brack

-

et, being careful not to bend the bracket or steel lines.

11 Remove the U

-

clip with a pair of pliers and separate the female

fitting from the bracket.

12 Disconnectthetwo hydraulic lines

atthe junction block, then un

-

bolt and remove the hose.

13

Boltthe junction blockto the axle housing and connectthe lines,

tightening them securely. Without twisting the hose, install the fe

-

male end of the hose in the frame bracket.

14 Install the U

-

clip retaining the female end to the bracket.

15 Using a back

-

up wrench, attach the steel line fittings to the fe

-

male fittings. Again, be careful not to bend the bracket or steel line.

16 Make surethe hose installation did not loosen theframe bracket.

Tighten the bracket if necessary.

17 Fill the master cylinder reservoir and bleed the system (refer to

Section 11).

Metal brake lines

18 When replacing brake lines besureto usethecorrectparts. Don't

use copper tubing for any brake system components. Purchase steel

brake lines from a dealer or auto parts store.

19 Prefabricated brake line, with the tube ends already flared and

fittings installed, is available at auto parts stores and dealers. These

lines are also bent to the proper shapes.

20 When installing the new line, make sure it's securely supported

in the brackets and has plenty of clearance between moving or hot

components.

21 After installation, check the master cylinder fluid level and add

fluid as necessary. Bleed the brake system as outlined in the next

Section and

testthe brakescarefully beforedrivingthevehicle in traf

-

fic.

11 Brake system bleeding

Refer to illustrations

11.8

and

I

I.

15

Warning:

Weareyeprotection when bleeding the brakesystem. Ifthe

fluid comes in contact with your eyes, immediately rinse them with

water and seek medical attention.

Note:

Bleeding the hydraulic system is necessary to remove any air

that manages to find its way into the system when it's been opened

during removal and installation of a hose, line, caliper or master cyl

-

inder.

Vehicles with conventional fnon-ABS) brakes

1

It will probably be necessary to bleed the system at all four

brakes if air has entered the system due to low fluid level, or if the

brake lines have been disconnected at the master cylinder.

2

If a brake line was disconnected only at a wheel, then only that

caliper or wheel cylinder must be bled.

3

If a brake line is disconnected at a fitting located between the

master cylinder and any of the brakes, that part of the system served

by the disconnected line must be bled.

4 Remove any residual vacuum from the brake power booster by

applying the brake several times with the engine off.

5 Removethe master cylinder reservoir cover and fill the reservoir

with brake fluid. Reinstall the cover.

Note:

Check the fluidleveloften

during the bleeding operation and add fluid as necessary to prevent

the fluid level from falling low enough to allow air bubbles into the

master cylinder.

6 Have an assistant on hand, aswell as a supply of new brake fluid,

a clear container partially filled with clean brake fluid, a length of

3116-inch plastic,

rubberorvinyl hosetofit overthe bleedervalveand

a wrench to open and close the bleeder valve.

7 Beginning at the right rear wheel, loosen the bleeder valve

slightly, then tighten

itto a pointwhere it is snug but can still be loos

-

ened quickly and easily.

8 Place one end of the hose over the bleeder valve and submerge

the other end in brake fluid in the container

(see illustration).

9 Have the assistant pump the brakes slowly a few times to get

pressure in the system, then hold the pedal firmly depressed.

10 While the pedal is held depressed, open the bleeder valve just

enough to allow a flow of fluid to leave the valve. Watch for air

bubbles to exit the submerged end of the tube. When the fluid flow

slows after a couple of seconds, close the valve and have your assis

-

tant release the pedal.

11 Repeat Steps 9 and 10 until no more air is seen leaving the tube,

then tighten the bleeder valve and proceed to the left rearwheel, the

right front wheel and the left front wheel, in that order, and perform

the same procedure. Be sure to check the fluid in the master cylinder

reservoir frequently.

12 Never

useold brakefluid. ltcontainsmoisturewhich willdeterio-

rate the brake system components.

13 Refill the master cylinder with fluid at the end of the operation.

14 Check the operation of the brakes. The pedal should feel solid

when depressed, with no sponginess. If necessary, repeat the entire

process.

Warning:

Do not operate the vehicle if you are in doubt

about the effectiveness of the brake system.

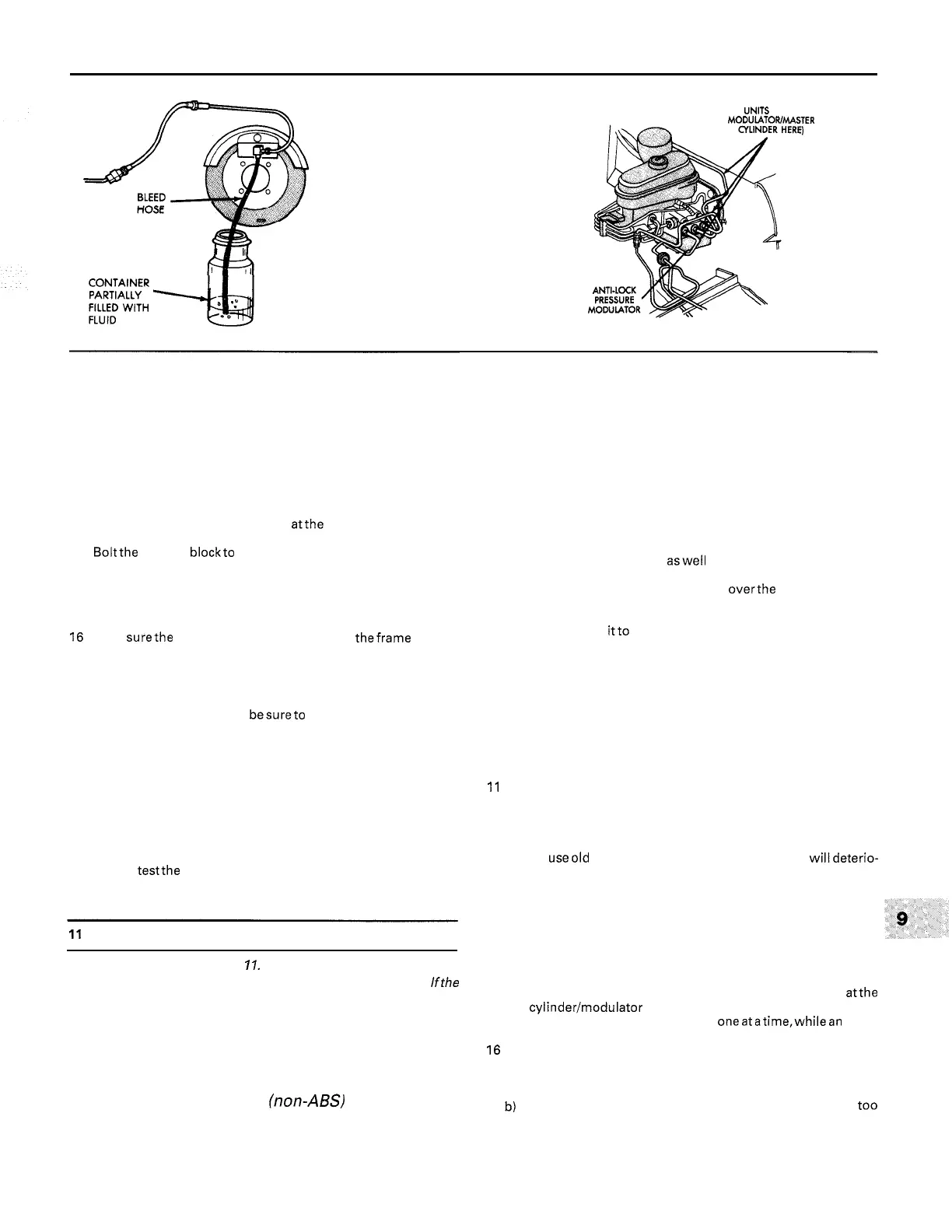

Vehicles with ABS brakes

15 Ifequipped with ABS brakes, begin by bleeding thesystem atthe

master cylinder/modulator

(see illustration).

This is done by loosen

-

ing and tightening the brake linefittings, oneatatime,whilean assis

-

tant operates the brake pedal. The ignition must be on.

16 The remaining bleeding operations are the same as for conven

-

tional brakes. However, note the following:

a) It is imperative that no dirt enter the system with the reservoir

cap off.

b) Insure that the fluid in the master cylinder does not drop too

low during bleeding, since this will lead to severe pump dam

-

age.

Loading...

Loading...