Models EELR538A and EELR539A

Models EELR540A and EELR541A

Installation, Operation and Maintenance

Page 8

Rev. 08/27/2021

15-18000-IOM-W.doc

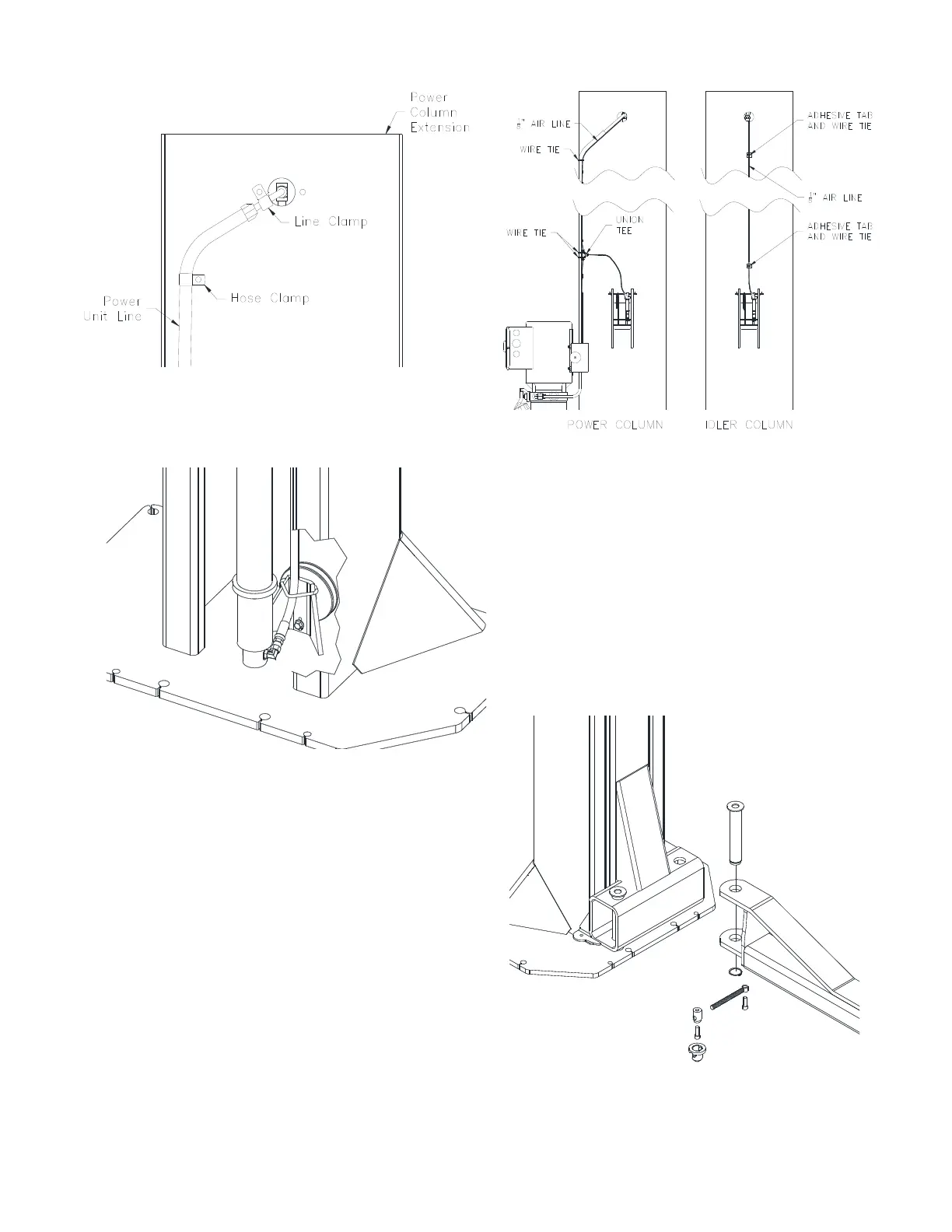

Fig. 13-Hose and Line Clamps

23) Hoses should connect to cylinders with a 90

degree elbow rotated 25 degrees upward and

be routed thru hose guide (Fig. 13B).

Fig. 13B-Hose Connection

24) B

E CERTAIN ALL FITTINGS AND CONNECTIONS ARE

TIGHT. IT IS THE INSTALLERS RESPONSIBILITY TO

INSURE SYSTEM IS LEAK

-FREE. Fill the Power Unit

with three gallons of clean 10wt anti-foam anti-

rust hydraulic oil or Dexron III ATF. D

O NOT USE

OILS WITH DETERGENTS.

L

OCK RELEASE

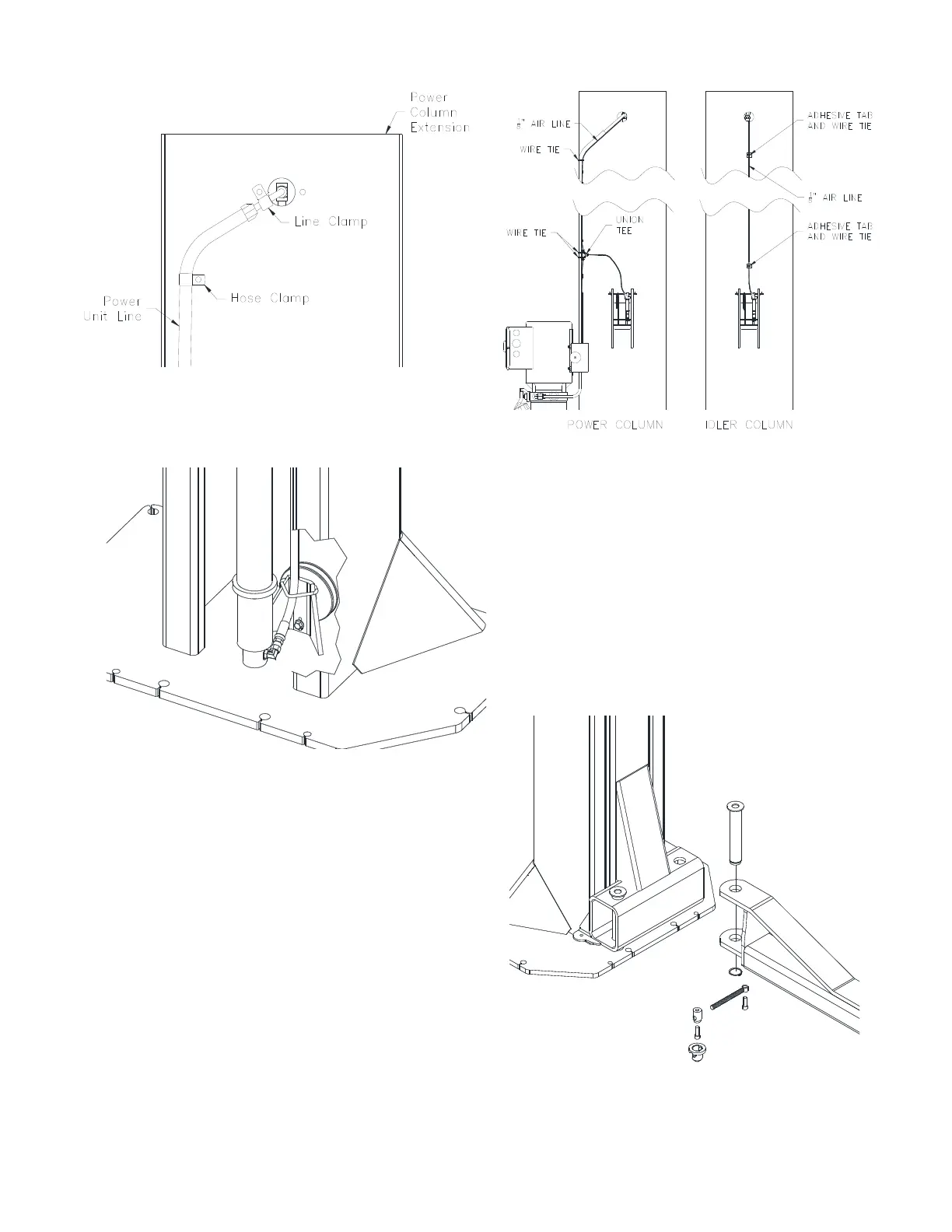

25) On the Power Column, attach the 1/8” air line

from the lock release air cylinder to the push-lock

tee fitting. Run another section of 1/8” air line

from the button valve to the tee (Fig. 14).

26) Connect the rest of the 1/8” air line to the top of

the tee and run it up the column attaching it to

the hydraulic line using wire ties (Fig. 14).

Fig. 14-Lock Release

27) After running the 1/8” air line along the hydraulic

line in the overhead and out the other opening in

the Idler Column (Fig. 14), run the air line down

the column using adhesive tab and wire ties.

Attach it to the lock release air cylinder (Fig. 14).

A

RM INSTALLATION

28) Lubricate the arm pin or carriage arm pin hole

with “anti-seize” and install the arms. Insure that

the arm restraint gears engage and disengage

properly. Arm restraints should disengage when

lift is fully lowered (Fig. 15).

29) Extend the footpad to both extents and apply

“anti-seize” to the retaining ring.

Fig. 15-Arm Installation

30) Make sure all the arm bolts are tight using a 3/8”

hex key. Slide all the arms out so they are fully

extended making sure that the male is retained

in the female.

Loading...

Loading...