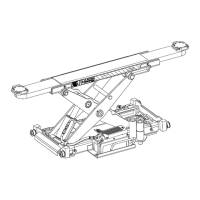

This document is an Installation, Operation & Maintenance Manual for a series of adjustable air-hydraulic rolling jack beams designed for alignment lifts. The models covered are EELS904A, EELS905A, and EELS906A.

Function Description

The rolling jack beam is an adjustable air-hydraulic device used in conjunction with alignment lifts to raise vehicles for service. It is designed to lift a vehicle by its frame engaging points, allowing for wheel-free access. The jack beam is positioned on the runways of an alignment lift and uses an air/hydraulic pump to raise and lower a vehicle. Mechanical safety locks are incorporated to secure the lifted load.

Important Technical Specifications

The manual provides detailed specifications for the three models: EELS904A, EELS905A, and EELS906A.

Capacity:

- EELS904A: 7,000 lbs. (3190kg)

- EELS905A: 7,500 lbs. (3420kg)

- EELS906A: 6,000 lbs. (2720kg)

Dimensions (approximate, varies slightly by model):

- Minimum Arm Reach: 35-7/16" (900mm)

- Maximum Arm Reach: 57-1/8" (1450mm)

- Minimum Drive Over Height With Pad Arm Retracted: 1-3/4" (44.1mm) to 1-13/16" (45.6mm)

- Minimum Pad Height Arm Extended: 2-9/16" (65mm)

- Minimum Lowered Height above Deck Surface (no stack pad): 15/16" (24.1mm) to 1" (25.6mm)

- Maximum Raised Height above Deck Surface (w/ pad): 16-1/2" (419.6mm) to 16-3/4" (426.6mm)

- Width Between Runways: 40" (1016mm) to 43" (1092mm)

- Minimum Floor Clearance: 5/8" (16mm) to 3-3/16" (80.9mm)

- Base Width: 32-1/4" (819mm)

- Adapter Length Range: 36-3/4" to 43" (921mm to 1092mm)

- Total Length: 24-3/4" (629mm)

Operational Requirements:

- Air Requirement @ 20 in3/min (flow rate): 90-120 psi (6-8bar)

- Maximum Operating Pressure @ Rated Load: 4700 psi (324bar)

- Shipping Weight: 408 lbs. (185kg)

- Recommended Hydraulic Oil: ISO 32 (10 weight) non-foaming and non-detergent hydraulic oil (Capacity: 1/2 Gallon / 1.89 L)

Environmental Conditions:

- Intended for indoor installation only.

- Operating environment temperature range: 41 – 104 °F (5 – 40 °C).

Usage Features

The jack beam is designed for ease of use and safety.

- Positioning: It rolls on the runways of the lift, allowing operators to position it precisely under the vehicle's lifting points. Roller adapters can be adjusted to center the jack body between the jack rails.

- Air-Hydraulic Operation: The device uses an air/hydraulic pump for lifting. The "PUMP" end of the pump is pressed and held to raise the jack beam, while the "RELEASE" handle is pressed down to lower it.

- Mechanical Safety Locks: The jack beam incorporates mechanical safety positions that automatically engage as the lift travels up, providing multiple working heights. A Safety Release Handle is used to disengage these locks during lowering.

- Adjustable Lifting Arms: The lifting arms can be extended to reach desired pickup points on the vehicle. It is crucial to extend them equally to avoid off-loading the vehicle.

- Stack Pads & Adapters: The system includes stack pads and adapters (3" and 6" options) to provide additional height as needed. It is important to use the same length stack adapter on each arm and in pairs.

- Low Profile Design: The WHEELFREE® jack system features a low profile, though operators are cautioned to inspect for low-hanging obstructions on vehicles before driving over.

- Storage Position: When not in use, the jack beams should be stored towards the center of the lift with the lift fully collapsed, and lifting pads removed if additional clearance is required.

Maintenance Features

Regular maintenance is essential for the safe and efficient operation of the jack beam.

- Daily Inspections:

- Check for proper working condition.

- Verify automatic engaging safety drops into place and releases correctly.

- Inspect air/hydraulic system for leaks.

- Check for loose bolts, broken/damaged components, and replace as required.

- Keep the entire jack beam clean.

- Ensure lifting arm stops work correctly by fully extending each arm.

- Inspect rubber lifting pads and replace if needed.

- Monthly Maintenance:

- Maintain a clean air source; an FRL (oil/lube/filter and regulator) should be in good working order. The air supply must be lubricated and include a water separator to prevent damage to the air/hydraulic motor and voiding the warranty.

- Check and clean rollers for proper functionality.

- Grease upper and lower slider block areas using multipurpose, extreme pressure grease (e.g., Megaplex XD5, NGLI grade 2 or equivalent).

- Annual Maintenance:

- Change hydraulic oil once a year for best results.

- Troubleshooting Guide: The manual includes a comprehensive troubleshooting section covering common issues such as the pump running but not lifting, pump not starting, lift not holding pressure, and slow lowering, along with their causes and remedies.

- Parts List and Exploded Views: Detailed exploded views and parts lists are provided for the total assembly, arm assembly, scissor assembly, and adapter assemblies (7K and 6K & 7.5K models), facilitating identification and replacement of components.

- Important Warning: Discontinue use immediately if any component is damaged, defective, worn, or broken, and contact customer service.

- Maintenance Schedule Log: A table is provided for recording all lift maintenance and operator training, encouraging systematic record-keeping.