Tube tension needs to be put on both rollers, see section 7. Rates of application are the same as

for a single pump and are detailed in the rate chart. Remember, “L” tubes apply twice as much

product as “B” tubes at the same RPM. You must calculate the effect of the sprockets for both.

4. Hose Arrangement

When you do not require all the squeeze tubes to be used, remove the tubes uniformly starting in

the middle taking one tube first from one side then the other. The plugs supplied should be installed

in the manifold in place of the tubes.

5. Plumbing

John Blue Company recommends using 1-

1

/

4

” ID hose between the tank and the pump. Smaller lines

may starve the pump reducing the application rate. Filters are recommended, but when rates are

lower than anticipated many times it is a filter that is clogged or the strainer mess is too small.

A loop at the end of the delivery line will prevent product from draining as it will stop air from entering

the hose to displace product. Since the pump is holding the product all that will drain is the small

amount that can be displaced by air up to the loop in the line. A ball valve should be used to shut

off any system when not in use to ensure no leakage occurs.

Always use Teflon tape or pipe joint compound on all connections. Never over tighten fittings as this

may cause them to crack. Check the squeeze tube screw clamps, as they may need to be retightened.

The screw clamps when installed on new squeeze tubes can cause the tubes to extrude slightly

under pressure of the clamp. As this occurs over time it is best to retighten the screw clamps slightly

before starting a new pump. Only retighten the screw clamps on the inlet side where the tube

is attached to the manifold. Do not retighten the fittings in the manifold; they are sealed at

the factory.

6. Chain Adjustment

The chain between the John Blue Squeeze Tube coned sprockets is adjusted by removing the

master link and moving the chain to the correctposition.

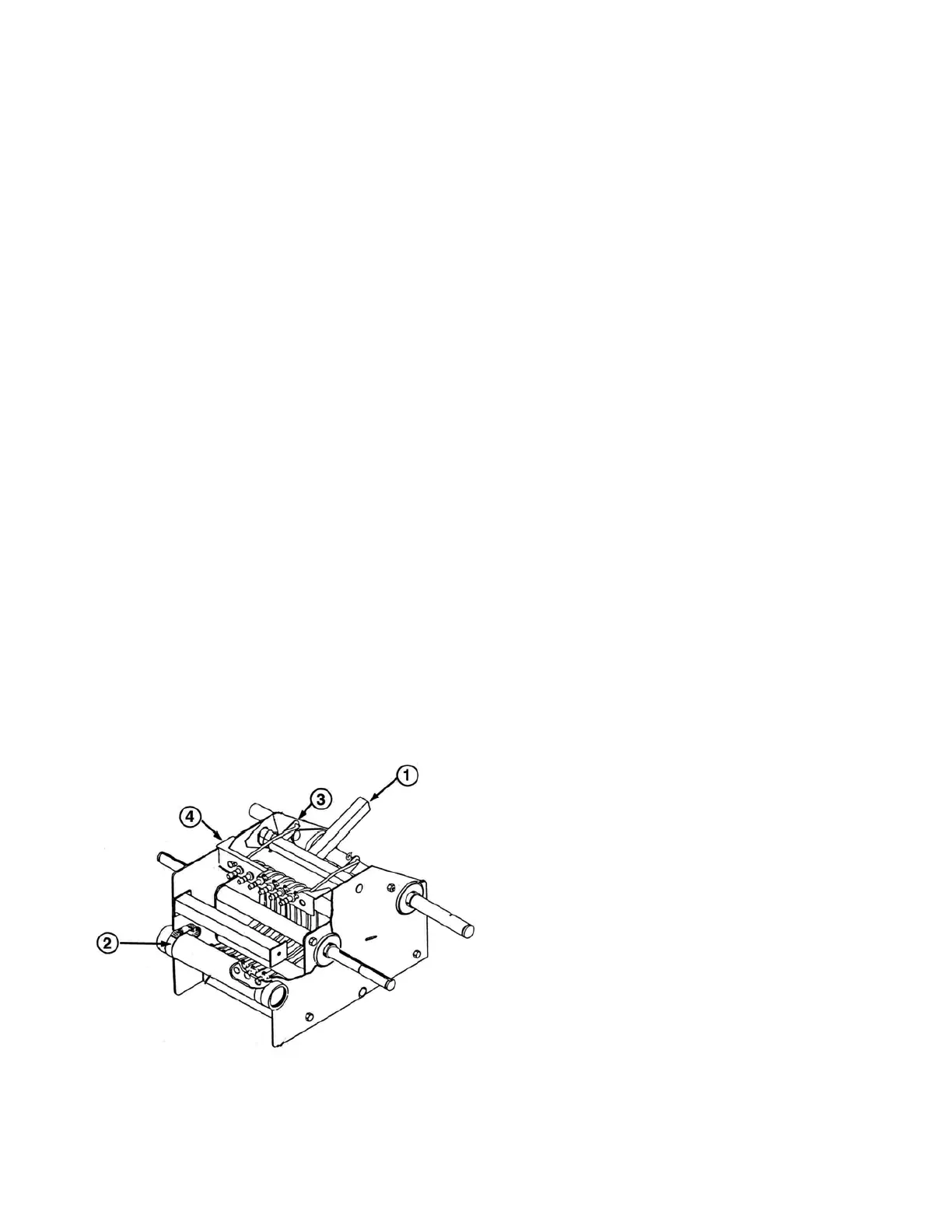

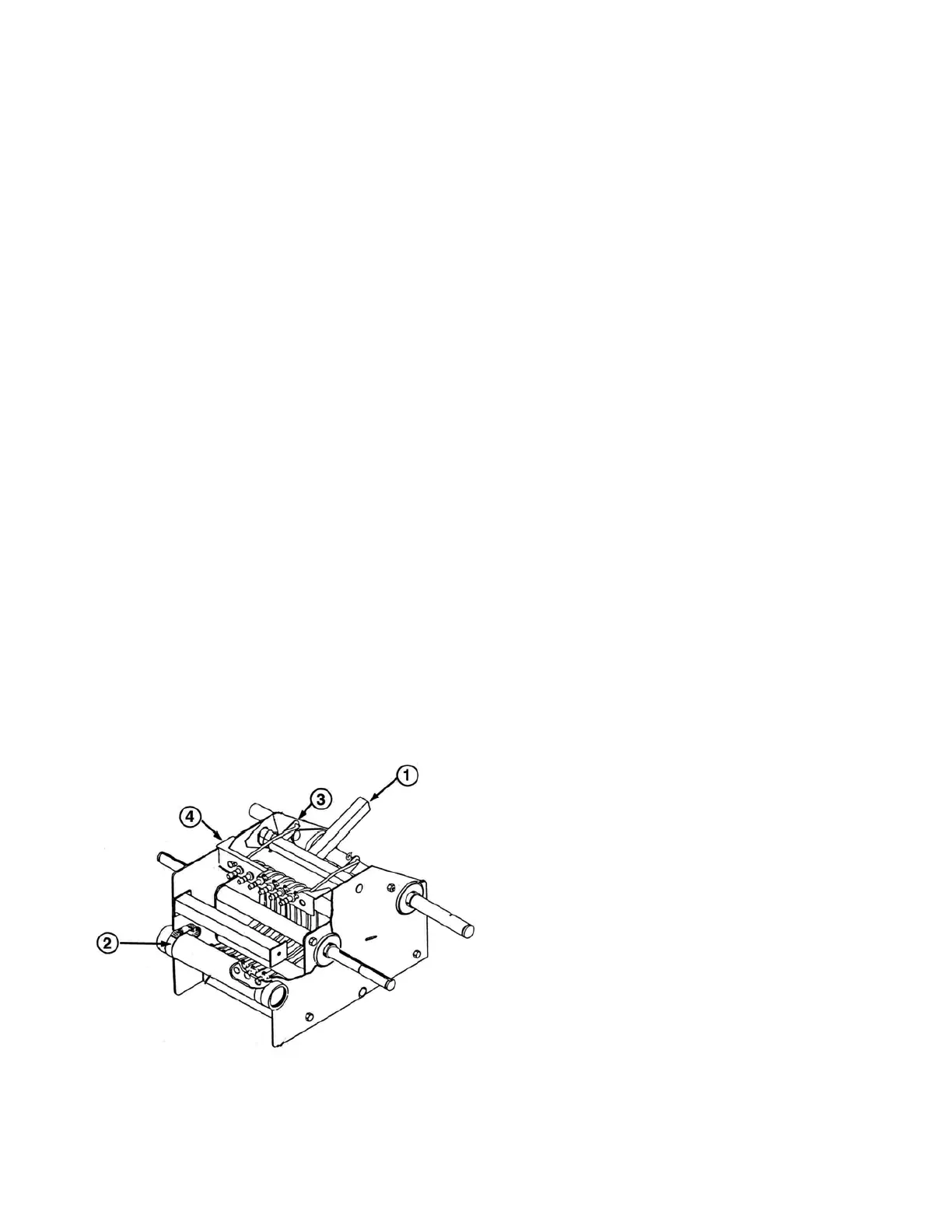

7. Tube Tension Adjustment

The oval-shaped tubes need to be stretched

across the four rollers in order to perform

efficiently. To tighten the tension on the tubes

insert the handle, supplied with the pump, on

the tube tension bar #1 (see drawing). Using

the handle pull forward toward the manifold #2

until the latch #3 engages into the notch on the

frame end plate. When engaged the outlet fitting

rack #4 will have been pushed forward and will

stay in the forward position. There are two

notches on the frame end plate, use only the

minimum tension to stop product from flowing

through the pump. For new pumps this is the

first notch. The pump will not work without tube

tension. When the pump is not being used, the

tension should be taken off the tubes by releasing

the latch #3.

Loading...

Loading...